Target

This experiment investigates how to use the ΔVBE concept to produce a stable (less sensitive to changes in input voltage levels) output current. Use feedback to build a circuit that produces a constant or regulated output current over a range of supply voltages.

Material

► ADALM2000 active learning module

►Solderless Breadboard

►A 500 Ω variable resistor, potentiometer

► One 100 Ω resistor

►Three small signal NPN transistors (2N3904)

►Three small signal PNP transistors (2N3906)

illustrate

Construct the circuit shown in Figure 1 on a solderless breadboard. The blue boxes indicate where to connect the ADALM2000. PNP transistors Q1, Q2, and Q3 form a current mirror with a gain of 2; the output current is twice the input current. NPN transistors Q4, Q5, and Q6 and variable resistor R1 form the ΔVBE portion of the circuit. Resistor R2 is used to measure the current flowing in the circuit (scope channel 2) as the voltage across the circuit changes (scope channel 1).

Figure 1. Floating current source (current sink connected to negative supply)

The output current is set by R1. The difference in VBE (ΔVBE) between Q4 and the parallel combination of Q5 and Q6 appears across R1. The gain of the PNP mirror (Q1, Q2, and Q3) is 2 (assuming they are the same size). Therefore, the current in Q4 is twice the current in Q5 and Q6 combined. If we further assume that Q4, Q5, and Q6 are also the same size and the current density ratio is 4, the difference in VBE will be:

Because of the absolute temperature term in this equation, the current will be proportional to the absolute temperature. This feature may be useful in some cases, but may not be desirable in other cases.

Figure 2. Floating current source (current sink connected to negative supply) breadboard circuit

Hardware Setup

The circuit connections of the breadboard are shown in Figure 2.

Procedure

Configure waveform generator W1 for a triangle wave with a frequency of 100 Hz, an amplitude of 10 V pp, and an offset of 0 V. The oscilloscope display should be set in both voltage and time and XY mode, with channel 1 on the horizontal axis and channel 2 on the vertical axis. Make sure to turn on the power supply after completing and double-checking the wiring.

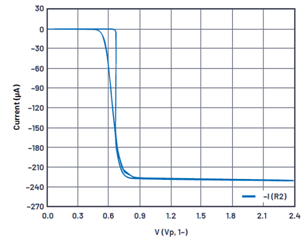

Figure 3. Example of an oscilloscope XY plot of a floating current source (current sink connected to negative supply).

Figure 4. Example of an LTspice XY plot of a floating current source (current sink connected to negative supply) using ideal components

Prove the floating nature of the circuit

In Figure 1, we used the negative supply as the negative reference for the circuit. To prove that this circuit is a true floating current source, rearrange the breadboard as shown in Figure 5 and repeat the measurement.

Figure 5. Floating current source (source current connected to positive supply)

Figure 6. Floating current source (current sink connected to positive supply) breadboard circuit

Hardware Setup

The breadboard circuit connections are shown in Figure 6.

Procedure

Configure waveform generator W1 for a triangle wave with a frequency of 100 Hz, an amplitude of 10 V pp, and an offset of 0 V. The oscilloscope display should be set in both voltage and time and XY mode, with channel 1 on the horizontal axis and channel 2 on the vertical axis. Make sure to turn on the power supply after completing and double-checking the wiring.

Figure 7. Floating current source (current sink connected to positive supply) XY plot

Figure 8. Example of an LTspice XY plot of a floating current source (current sink connected to positive supply) using ideal components

question:

By analyzing the LTspice® diagram of the circuit, what is the minimum voltage required for the current source to maintain a relatively constant current?

You can find the answers to your questions on the StudentZone blog.

About the Author

Doug Mercer graduated from Rensselaer Polytechnic Institute (RPI) in 1977 with a bachelor’s degree in electrical engineering. Since joining Analog Devices in 1977, he has contributed directly or indirectly to more than 30 data converter products and holds 13 patents. He was named an ADI Fellow in 1995. In 2009, he transitioned from full-time employment and continues to serve as a consultant to ADI as a Fellow Emeritus, contributing to the Active Learning Program. In 2016, he was named Engineer-in-Residence for the ECSE Department at RPI. He can be reached at doug.mercer@analog.com.

Antoniu Miclaus is a system applications engineer at Analog Devices, working on ADI educational projects and developing embedded software for Circuits from the Lab®, QA automation, and process management. He joined Analog Devices in February 2017 in Cluj-Napoca, Romania. He is currently an MSc student in the Master’s program in Software Engineering at Bebis Bolyai University and holds a B.A. in Electronics and Telecommunications Engineering from the Technical University of Cluj-Napoca. He can be contacted at antoniu.miclaus@analog.com.

Previous article:How to Select a Boost Regulator/Controller IC and Choose Peripheral Components Using LTspice

Next article:Double Pulse Testing Basics Series: Basic Principles and Applications

- Popular Resources

- Popular amplifiers

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Download from the Internet--ARM Getting Started Notes

- Learn ARM development(22)

- Learn ARM development(21)

- Learn ARM development(20)

- Learn ARM development(19)

- Learn ARM development(14)

- Learn ARM development(15)

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- What is the maximum output current of LM358?

- [ESP32-S2-Kaluga-1 Review] 2. Run littlevgl?

- MSP430F5438A upgrade failed

- Salt spray test chamber shows the solution to the problem

- "Playing with the board" + The first article #Running ModbusTcp on EK-TM4C1294XL

- trinamic open source KICAD stepper motor control board

- [Bluesun AB32VG1 RISC-V Evaluation Board] Settings and selections for program development

- Get a gift when you grab a building | Infineon Tmall store gives you a surprise!

- Why can't this circuit achieve bistable state?

- Power Management Guide

LF156H/883/NOPB

LF156H/883/NOPB

京公网安备 11010802033920号

京公网安备 11010802033920号