When an alternate path to ground is established, a residual current operated device (RCD) or residual current circuit breaker (RCCB) detects leakage current. RCDs isolate the power source from the leakage path by breaking the circuit. Unlike fuses, these types of circuit breakers can be reset and reused, and they play an important role in protecting people and equipment.

In this article, the requirements for RCD leakage current detection and tripping will be reviewed, and how ultra-low power voltage monitors or reset ICs can be used as leakage current detectors. It will also be shown how voltage monitors benefit medium voltage circuit breakers such as air circuit breakers (ACBs) and molded case circuit breakers (MCCBs) using microcontrollers.

Using Voltage Monitors as Leakage Current Threshold Detectors

Leakage current occurs when faulty equipment or electric shock occurs, and RCDs are designed to respond to currents of 5 mA-500 mA. As stated in the International Electrotechnical Commission TS60479-1 standard, a person will experience muscle contraction within 200 ms at 50 mA, and exposure for more than 3 seconds will increase the likelihood of ventricular fibrillation.

RCDs detect leakage current by sensing the difference between the active line and neutral currents. If the line current and neutral current are unbalanced and the leakage current exceeds a predetermined threshold, the circuit breaker trips, interrupting and isolating the power supply. RCD devices can be divided into three main stages. The first is the sensing stage, during which the leakage sensor senses the leakage current. In the second stage, the detection circuit sets the leakage current threshold. In the third stage, the relay trips to isolate the leakage source.

In the past, relays were used as detection circuits to set the leakage current threshold. Modern RCDs use integrated circuits such as voltage monitors to improve the accuracy and response time of detecting leakage current and driving solenoid relays.

Figure 1 shows how TI's TPS3840 voltage monitor detects leakage current. In this example, the leakage sensor (such as a differential current transformer or a zero-phase current transformer) is represented by a current source. For the current sensing circuit, a resistor divider is used to convert the input current to a voltage, which is then detected by the TPS3840. The TPS3840 integrates a precise reference voltage bandgap and a voltage comparator. The trigger point is programmed at the factory via a one-time nonvolatile memory (OTP), and the voltage threshold can be set from 1.6 V to 4.9 V with a typical accuracy of 1%.

When the voltage on the VDD pin rises above the threshold, the RESET pin will pull high to interrupt the microcontroller or drive an electromagnetic relay. In addition, a single external capacitor can be used to extend the RESET response time to meet varying RCD response times depending on the magnitude of the leakage current.

Figure 1: Nanopower, wide input voltage (up to 12V) supervisor reference design used as a comparator or power sequencer

This reference design highlights the common use cases of low-power reset ICs and watchdog timers. With a current consumption of less than 1µA, the TPS3840 device can be configured to act as a comparator (via a simple 3-pin configuration) or as a general-purpose power supervisor, which can be daisy-chained as a sequencer. In addition, the response and delay times can be configured via external capacitors. For applications that require a running watchdog, the TPS3431 device can be used, which is a stand-alone programmable watchdog timer with an accuracy of ±2.5% (typical).

Features

Threshold Detection (TPS3840): Self-powered threshold detector using a voltage monitor as a comparator (via 3-pin configuration, no external power supply).

Very low quiescent current (<700nA) architecture with a set threshold range of 1.6V–4.9V (0.1V step); fast power-up (startup delay <250µs) with user-controllable response time (80µs to 600ms via external capacitor).

Power Supply Monitoring and Sequencing Reset (TPS3840): Can be used for multi-rail reset monitoring and startup sequencing.

Available in active-low and active-high configurations, with a threshold range of 1.6V–4.9V and a TD range of 80µs–600ms.

Watchdog Timer (TPS3431): User-adjustable timer with enable pin and wide input range.

Low current consumption (up to 20µA) for watchdog functions and user-configurable timeout functions with external resistors and capacitors.

This reference design highlights common use cases for low-power reset ICs and watchdog timers. The TPS3840 device consumes less than 1µA and can be configured to operate as a comparator (with a simple 3-pin configuration) or as a general-purpose power monitor and can be daisy-chained into a sequencer. In addition, the response and delay times can be configured using external capacitors. For applications that require watchdog operation, the TPS3431 device can be used, which is a stand-alone programmable watchdog timer with ±2.5% accuracy (typical). The

voltage monitor in this reference design meets three key specifications:

fast power-up and programmable response time. When the voltage monitor rises from zero input voltage to the trip point or above the threshold voltage, it takes a certain amount of time to start and react. Circuit breakers need to detect leakage current levels quickly and have the flexibility to configure the trip response time based on the leakage level and duration to avoid nuisance tripping caused by transients. The TPS3840 has a startup time of 200 µs for fast response.

Ultra-low input current. In Figure 1, the power supply pin (VDD) of the supervisor IC is aligned with the input signal monitoring pin (SENSE). Since it is powered by the input signal, the voltage supervisor should have high input impedance to minimize the error (IIN) across the voltage divider (IDIV). The TPS3840 voltage supervisor consumes ultra-low current with a typical IQ of 350 nA and

a low VPOR to achieve a low VOL. VPOR is the minimum input voltage required for the controlled output state. When VIN < VPOR, the output tracks the input and may trigger a relay. VPOR should be as low as possible to provide margin between the enable voltage level of the relay and the voltage supervisor low output voltage level (VOL). The TPS3840 is available in an active-low configuration with a low VPOR and a VOL of 300 mV to avoid false resets.

Using a Voltage Supervisor as a Supervisor for a Microcontroller

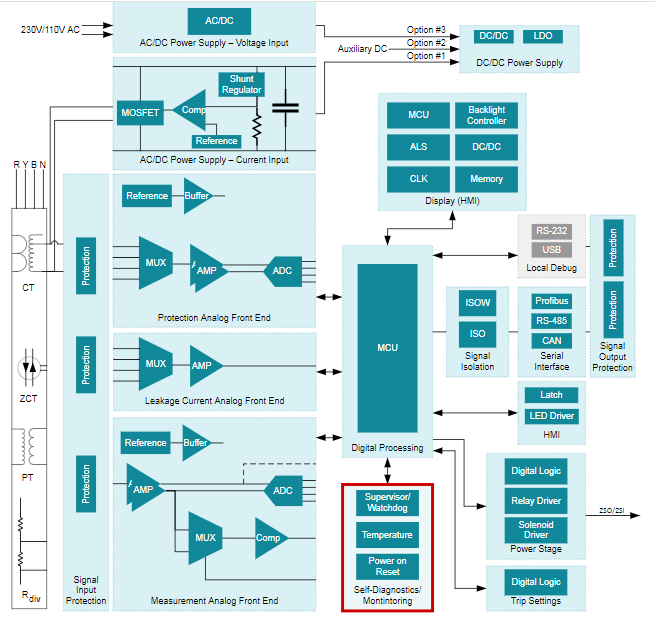

Figure 2 shows the block diagram of the reference design for air circuit breakers (ACB) and molded case circuit breakers (MCCB), which require a microcontroller that can detect overcurrent and ground current faults. Low IQ voltage supervisors such as the LM8364 or TPS3840 can monitor the power rails. The TPS3840 has a wider operating temperature range and lower IQ than the LM8364.

If the voltage supervisor is integrated into the microcontroller, an external watchdog timer is recommended. The external watchdog ensures that the microcontroller does not latch up by periodically detecting pulses sent by the microcontroller's general purpose input/output pins. If the software fails and misses a pulse, the external watchdog timer can reset the microcontroller. The

TPS3430 programmable watchdog timer is a good choice because it provides a programmable watchdog, monitors timeouts, and reset delays to meet the timing requirements of any microcontroller. If higher reliability is required, a voltage supervisor and watchdog should be used together. The TPS3823 integrated watchdog and voltage supervisor is a good choice, providing fixed threshold and watchdog timeout options.

Figure 2: Signal processing subsystem and current input-based self-powered (ACB/MCCB)

voltage monitor for circuit breaker applications not only monitors the microcontroller's voltage supply to ensure proper operation, but also acts as a leakage current detector, helping to enhance your circuit breaker design.

The reference design uses a signal processing front end and self-powered modules for electronic trip units (ETUs) used in circuit breakers. This design uses a FRAM-based microcontroller to process current inputs from signal conditioning amplifiers to obtain three-phase neutral-ground currents. Two gains are used to extend the phase current measurement range.

This reference design can also be self-powered using rectified current inputs. The TIDA-00498 is designed to achieve fast and repetitive tripping (within 30mS) over a wide current and temperature range.

Features

measure three currents (phase) with an input range of (0.2 to 12 INOMINAL) and two currents (neutral, ground) with an input range of (0.05 to 2 INOMINAL) with an accuracy of ±3%.

Fast startup using TI's MSP430 FRAM MCU, startup time including single cycle RMS compensation is less than 30ms.

Brown-out detection provides a reset time of approximately 200μs after power-on.

Self-powered supply (from rectified current input) with MOSFET-based shunt regulation.

Previous article:What are the requirements for voltage monitors in smart meters?

Next article:Four days and three nights of the national competition "brick moving team"

- Popular Resources

- Popular amplifiers

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Please tell me the role of these two resistors in the circuit

- Is the naked-eye 3D large screen also made of light-emitting diodes (LED)? What is the principle?

- Comparison of TI's tms320 series DSP

- Playing with Zynq Serial 45——[ex64] Image Laplace Sharpening Processing of MT9V034 Camera

- New employee: I am the most idle person in the company, so my boss assigned me to write the bootloader

- I feel like I can't stay in this stupid company any longer.

- TI High Power Density Solution Analysis!

- Can the CH246 & CH241 wireless charging kit be used like this?

- Thank you for your strong faith

- Overview of MCU bus, three-bus structure of MCU

A 1.6 V 80 μW rail-to-rail constant-GM bipolar adaptive biased op-amp input...

A 1.6 V 80 μW rail-to-rail constant-GM bipolar adaptive biased op-amp input...

京公网安备 11010802033920号

京公网安备 11010802033920号