In the past, LED bulb drivers required a large number of external components, expensive isolation components, and special design strategies to prevent long-term aging problems of key components (such as electrolytic capacitors). Now, the integration of driver circuits makes bulbs more prone to reliability problems, such as early failure or reduced MTTF (mean time to failure) rates.

MTTF is a measure of the time to first failure, usually calculated as the FIT rate (failure rate per billion hours) of each component in the circuit. Since the driver circuit needs to reduce the large AC voltage (100Vac/220V ac) to a DC voltage that can power the LED, electrical isolation is required for safety reasons.

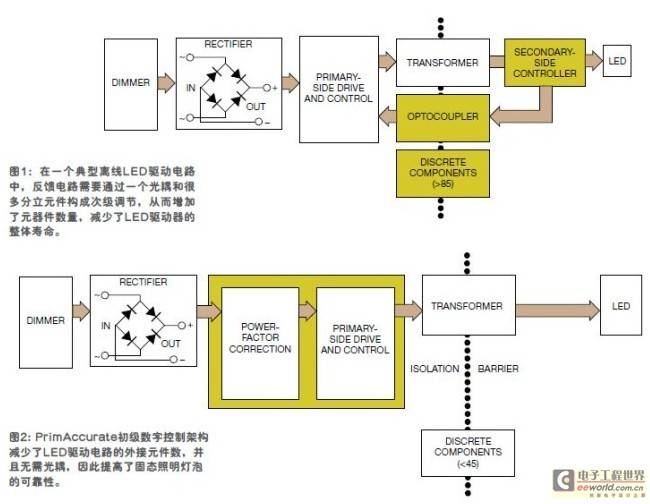

In a typical electrically isolated AC/DC converter, a discrete optical isolator (or optocoupler) is used to provide feedback from the secondary side to the primary side controller. It converts an electrical signal into an optical signal, passes the signal through an optical barrier, and then converts it back to an electrical signal (Figure 1). Because the FIT rate of the optocoupler is higher than that of semiconductor components, it reduces the MTTF of the entire circuit.

In addition, due to the effects of aging, the current transfer rate of the optocoupler may change over time and temperature. This change will affect the circuit stability of the power supply and shorten the life of the LED driver circuit. Although many LED lamps and luminaires can operate at high PCB temperatures, designers must eliminate these weak links to achieve longer life.

Figure 2 shows iWatt's primary-side digital control technology, PrimAccurate. This patented solution uses real-time waveform analysis to detect the LED current through the primary side of the isolation transformer without requiring direct feedback from the output, while maintaining tight constant-current regulation of the LED string.

Another benefit of this technology is the internal feedback loop compensation, which simplifies the design, reduces the number of external components, and especially eliminates the need for optocouplers, which have the highest FIT rate, improving the reliability of the LED driver circuit and thus improving the overall reliability of the bulb.

LED bulbs produced today must also be backwards compatible with existing lighting technology in the home. Dimmers provide mood lighting in the home, and one benefit of LED lighting as an incandescent replacement is that it can be easily dimmed, matching the characteristics of incandescent bulbs more efficiently than fluorescent lamps.

However, to support dimming functions, LED drivers need to control multiple factors, including dimmer detection, compatibility, and light flicker. To optimize the operating life of the lighting system, one concern when using dimmers with LED drivers is durability.

A typical A-type incandescent bulb is purely resistive. When a dimmer is used to control the brightness of an ordinary A-type bulb, the load on the dimmer is also purely resistive, and a constant current passes through the dimmer, which can be controlled.

The LED driver is actually a current source, and its input terminal has high capacitance to the dimmer. When powered on, a huge surge current will appear to charge the capacitive load, and then stabilize to a much lower current level. This surge current may damage the standard dimmer, and this current must be reduced to avoid damaging the life of the dimming circuit.

One solution to the dimmer inrush problem is to use a two-stage solution to drive the LED instead of a direct flyback converter approach, which has a high capacitive input impedance. In a two-stage solution, the primary is used to increase the impedance to a controllable level, thereby reducing the inrush current and providing the required safety and protection for the dimmer.

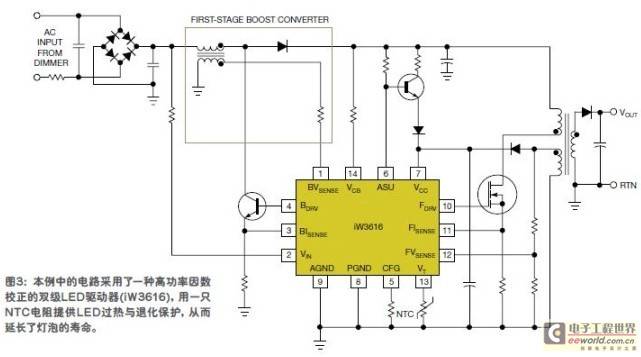

iWatt's iW3616 LED driver (Figure 3) uses a two-stage solution, which has an initial boost converter with a dual function: first, to provide the required load impedance for the dimmer and reduce inrush current; second, to keep the input current in the same phase as the supply current to improve the power factor of the entire circuit. This solution not only prolongs the life of the dimmer, but also produces a high power factor. The digital block that provides primary-side control in the iW3616 contains a detection algorithm that can be used with almost all off-the-shelf dimmers on the market. The same algorithm also controls the boost converter, optimizing the circuit's dynamic input impedance to improve the power factor and reduce inrush current.

When optimizing the operating life of an LED bulb, an equally important consideration is the life expectancy of the LED itself. As with all semiconductor components, the higher the operating junction temperature of the LED, the shorter its life expectancy. Electrolytic capacitors also have a life expectancy that is also dependent on the operating temperature.

One solution is to reduce the rated drive current of the LED and simply use more LEDs to produce a specific amount of light output, so that less heat is generated on a single LED, thereby reducing the junction temperature. This approach can extend the operating life of the bulb, but in exchange for a higher solution cost because more LEDs are required. In addition, it cannot adapt to external factors, such as the physical size characteristics of the lamp, which may generate more heat than expected.

Another method is to optimize the maximum current of the LED, that is, to set a maximum junction temperature, which will trigger a drop in the LED current to avoid aging. Existing digital LED driver controllers implement a two-level protection mechanism, and designers can set the maximum LED temperature with an external device. An NTC (negative temperature coefficient) resistor is placed near the LED junction as a temperature monitor. The NTC resistor is connected to the LED driver IC, and a temperature feedback device is used to protect the LED.

The iW3616 in Figure 3 uses an NTC device to protect the LED in the LED bulb. If the LED junction reaches the maximum temperature threshold set by the NTC element, the controller reduces the LED current in 10% intervals until the temperature stabilizes. If the temperature drops, the LED current gradually returns to its maximum setting value in the same reverse 10% step, with an appropriate amount of hysteresis to prevent oscillation. If a major fault event occurs, the failure recovery mode can reduce the current through the LED to 1% of the preset output current. This overheat protection structure provides design flexibility for LED bulbs, and will still provide complete protection for the bulb under extreme working conditions, and designers no longer have to worry about such problems.

LEDs have developed to a stage where cost and light output are comparable to other competing solutions, and LED lighting is striving to become a practical alternative to incandescent lighting in homes. The key to the success of this new technology is the implementation of the driver. In order to ensure that LEDs truly have the long working life they claim to have, in addition to the efficiency and cost parameters that designers are working hard to optimize, other factors are also very critical, such as temperature, dimming control and reliability.

LEDs require a circuit driver to convert the standard AC voltage into a usable DC current and voltage.

To make LED bulbs compatible with standard lamp sockets without sacrificing their operating life, designers must integrate the driver circuitry with the bulb in a way that does not increase the potential failure mechanisms of the bulb.

The drive circuit needs to convert the high AC voltage into a low DC voltage, so electrical isolation is necessary. One solution is to use real-time waveform analysis to detect the LED current through the primary side of the isolation transformer. In this way, strict constant current regulation of the LED string can be maintained without direct feedback from the output.

The two-step approach to driving LEDs uses a boost converter in front to provide the required load impedance for the dimmer (reducing potentially damaging inrush current) and to bring the input current into phase with the line current, thereby improving the overall power factor of the circuit.

Governments around the world have introduced regulations requiring the gradual phase-out of incandescent bulbs, which has driven the transition to solid-state lighting technology. LED lighting has obvious advantages over traditional methods, especially LED bulbs have improved lumen performance per watt and reduced cost per lumen.

The main benefits of LED technology over the traditional incandescent bulbs they replaced are longer operating life and lower operating cost per watt-hour. The robustness of solid-state lighting technology is a major selling point to consumers compared to the relatively fragile incandescent and fluorescent bulbs. The typical life of an incandescent bulb is about 1,000 hours (Reference 1). LED bulbs are claimed to have an operating life of more than 50,000 hours (Reference 2) while consuming only about 20% of the power of the former at equivalent light output.

However, if designers do not take some necessary precautions, LED lighting may not be able to deliver on its promise to consumers of approximately 25 years without the need to replace a bulb. The complexity and reliability of LEDs and their driver circuits (which must also be compatible with traditional dimming techniques) are issues that designers must consider and address in order to obtain the longest operating life of LED lighting systems.

LEDs require a constant DC current for normal operation, and the voltage is much lower than the rectified AC line voltage, so a driver circuit is needed to reduce the standard AC voltage to a usable level. To make LED bulbs compatible with standard lamp sockets, designers must integrate the driver circuit into the bulb. If not handled properly, this integration will increase the possibility of mechanical failure of LED bulbs.

Previous article:LED circuit knowledge

Next article:Synchronous buck switching power supply driving LED array

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Mobile phone calculators are all dead: What is 10% + 10%? [Have you ever calculated it?]

- When the serial port is connected, if the host receives wrong data, it will return to the initial state.

- How to set the temperature of the battery temperature detection pin TS of BQ24650 to -10℃-50℃

- Summary of DSP CMD file writing method

- IC WKN Driver Laser Diode

- [Live broadcast on May 9] Discussing solutions to reduce downtime in the new manufacturing era, ADI live broadcast expert Zhao Yanhui is here again

- MOS tube isolation drive circuit, if we drive high voltage MOS tube, we need to use transformer drive and integrated...

- Watch NXP LPC55S69 live broadcast and get the book "Embedded Security Processor Application and Practice" for free

- EEWORLD University ---- SimpleLink Academy: Develop your Bluetooth? Low Energy project

- dsPIC33EP32MC204PWM current limiting function problem

Multimodal perception parameterized decision making for autonomous driving

Multimodal perception parameterized decision making for autonomous driving CVPR 2023 Paper Summary: Robotics

CVPR 2023 Paper Summary: Robotics

京公网安备 11010802033920号

京公网安备 11010802033920号