1. Introduction

Light control circuit plays a vital role in urban street lamps or corridor lighting. With light control circuit, the lights can be automatically turned on and off according to the light intensity, so as to achieve unmanned automatic control, reduce the labor intensity of workers and effectively save energy. However, light control circuit has its defects, that is, when there is no light at night, the lights will keep working, which will cause a waste of resources and shorten the life of the lights.

At this time, if a sound control circuit is added to the light control circuit, the lighting circuit will be controlled only by sound when there is no light, and the lighting circuit will automatically work when there are footsteps or other strong sounds. When the sound disappears, the lighting will automatically go out. This requires adding a delay circuit under the condition that the light control circuit and the sound control circuit work together, so that the lighting will automatically go out after a certain delay after being lit.

This article designs a sound and light control lighting lamp. When there is a sound signal at night, the lighting lamp (simulated by LED light-emitting tube) lights up; when there is no sound, it will go out after a delay of 5 seconds; if the sound interval is less than 5 seconds, the LED will continue to light up. During the day, it will not light up with or without sound. This small, beautiful, practical and energy-saving device can be fixed at the door of your home with mosquito nails or installed in the corridor. It can also be used in factories and construction sites.

With this lighting circuit, people don't have to fumble for switches in the dark, and don't have to worry about wasting electricity and damaging bulbs by turning on lights all the time. At night, as long as there are footsteps or other strong sounds, the lights will automatically light up and automatically turn off after a certain delay. It is particularly suitable for automatically controlling street lighting and short-term lighting in corridors and stairways.

2. Corridor sound-controlled light circuit design

2.1 Basic principles of corridor sound-controlled lights

This circuit is composed of a sound control circuit, a light control circuit, an amplifier circuit, and a monostable delay circuit. The functions are analyzed one by one and the circuit structure is determined as follows.

The light control circuit determines the light on and off of the lamp according to the intensity of the light. The sound signal is received by the electret microphone BM, and after inverse amplification, the amplified signal is sent to the 2nd and 6th pins of the NE555 timer. This circuit can control the sound control delay circuit. When the light is strong during the day, the circuit is in a closed state under the action of the light control circuit and does not respond to any sound signal. When the light is weak at night, the light control circuit turns on the function of the circuit, so that the circuit can respond accordingly to the external sound signal. The output of the NE555 timer controls the 74HC123 sound control delay circuit. This circuit mainly works when the light is weak. This is mainly controlled by the output of the light control circuit.

Figure 1 Corridor sound-controlled light circuit diagram

2.2 Introduction of components

Device List

Table 1 Device List

|

74HC123

one piece

|

NE555

one

|

LM358

one

|

One electret microphone

|

|

Resistors:

330

Ω

2;1K/4;4.7K/5;10K/2;150K/2

|

Potentiometer single turn blue square one

22K

Ω

|

Capacitor:

One

16V 47uF

;

Two

16V 10uF

;

|

Photoresistor; One light-emitting diode

LED

;

|

2.2.1 Resistors

There are many types of resistors, which are usually divided into three categories: fixed resistors, variable resistors, and special resistors.

A photoresistor is a component whose resistance value changes with the intensity of external light (brightness or darkness). The stronger the light, the smaller the resistance value, and the weaker the light, the larger the resistance value. A photoresistor, also known as a photoresistor, is a resistor made using the photoelectric effect of a semiconductor. Its resistance value changes with the intensity of the incident light. It is generally used for light measurement, light control, and photoelectric conversion (converting light changes into electrical changes).

Usually, photoresistors are made into thin-film structures to absorb more light energy. When it is irradiated by light, electron-hole pairs are excited in the semiconductor sheet (photosensitive layer) to participate in conduction and increase the current in the circuit.

2.2.2 Electret Microphone BM

The electret microphone has the characteristics of small size, simple structure, good electroacoustic performance and low price. It is widely used in cassette recorders, wireless microphones and voice control circuits. It is the most commonly used condenser microphone. Because the input and output impedances are very high, a field effect tube must be set in the shell of this microphone as an impedance converter. For this reason, the electret condenser microphone requires a DC working voltage when working. Structure and principle The electret microphone consists of two parts: acoustic-electric conversion and impedance conversion.

The key element of acoustic-electric conversion is the electret vibrating membrane. It is an extremely thin plastic membrane with a layer of pure gold film evaporated on one side. Then after being electret in a high-voltage electric field, opposite charges are respectively deposited on both sides. The evaporated gold side of the membrane faces outward and is connected to the metal shell. The other side of the membrane is separated from the metal plate by a thin insulating liner. In this way, a capacitor is formed between the evaporated gold film and the metal plate. When the electret membrane encounters sound wave vibration, the electric field at both ends of the capacitor changes, thereby generating an alternating voltage that changes with the sound wave. The capacitance between the electret membrane and the metal plate is relatively small, generally tens of pF. Therefore, its output impedance value is very high (Xc = 1/2 ~ tfc), about tens of megohms or more. Such a high impedance cannot be directly matched with an audio amplifier. Therefore, a junction field effect transistor is connected to the microphone for impedance conversion. The characteristics of the field effect transistor are extremely high input impedance and low noise coefficient. Ordinary field effect tubes have three electrodes: source (S), gate (G) and drain (D). Here we use a special field effect tube with a diode compounded between the internal source and gate. The purpose of connecting the diode is to protect the field effect tube when it is impacted by a strong signal. The gate of the field effect tube is connected to the metal plate. In this way, the output line of the electret microphone has three wires. That is, the source S, which is generally made of blue plastic wire, the drain D, which is generally made of red plastic wire and a braided shielding wire connected to the metal shell.

Figure 2 Electret microphone

2.3. Working principle of electret microphone

The electret microphone has a small size, simple structure, good electroacoustic performance, low price and is widely used.

A certain permanent charge (Q) is injected into the polymer polarization film during production. Since there is no discharge circuit, the amount of charge remains unchanged. Under the action of sound waves, the polarization film vibrates with the sound, so the distance from the back electrode also changes. That is, the capacitance between the polarization-locked film and the back electrode changes with the sound waves.

We know that the formula for the charge on a capacitor is Q = C × V, and vice versa V = Q/C. The total charge of the electret remains unchanged. When the plate retreats under the pressure of the sound wave, the capacitance decreases, and the voltage between the two poles of the capacitor will increase inversely proportionally. Conversely, when the capacitance increases, the voltage between the two poles of the capacitor will decrease inversely proportionally. Finally, the voltage across the capacitor is taken out through the field effect with very high impedance, and amplified at the same time, we can get the voltage corresponding to the sound. Since the field effect tube is an active device, it requires a certain bias and current to work in the amplified state. Therefore, the electret microphone must add a DC bias to work.

2.4. Notes on choosing electret microphones

The price of electret microphones is very low, and they can be replaced after being damaged. The following points should be noted when selecting electret microphones:

(1) Two-pin and three-pin electret microphones cannot be directly substituted, and generally the circuits cannot be changed.

(2) There is no model distinction for this type of microphone. Microphones with the same number of pins can be replaced, with only differences in performance.

2.5 555 Timer Circuit

The integrated timer 555 circuit is a medium-scale integrated circuit with a digital and analog hybrid type, which is widely used. It is a circuit that generates time delays and multiple pulse signals.

The standard uses three 5K resistors, so it is named 555 circuit. There are two types of circuits: bipolar and CMOS. The structure and working principle of the two are similar. The logical function and pin arrangement of the two are exactly the same, and they are easy to interchange.

The 555 circuit constitutes a monostable trigger, as shown in Figure 3.

Figure 3 Monostable trigger

The internal circuit of the 555 timer is shown in Figure 4.

Figure 4 Internal structure of 555 timer

2.6 74HC123

74HC123 is a monostable trigger. Its RxCx (7,15) and Cx terminals (6,14) are connected to the timing resistor and capacitor, which determines the width of the single pulse generated at the Q terminal after triggering. Rbar (3,11) is a low-level reset, and is a high level when not reset. Abar (1,9) is a falling edge trigger input terminal, which is triggered by a negative pulse through Abar and remains high when not in use. B (2,10) is a rising edge trigger input terminal, which is triggered by a positive pulse through B and is set low when not in use... Q (5,13) and Qbar (4,12) output positive and negative timing single pulses respectively.

The function of the monostable trigger in the device is to restore the state before the trigger by only maintaining the period of time given by the external resistors and capacitors, no matter how long the trigger signal lasts. The external resistors and capacitors determine the monostable time, because the trigger is triggered by the edge, rising or falling edge. The difference between the retriggerable monostable is that the monostable after the previous trigger has not restored the state before the trigger and there is a trigger signal, the retriggerable monostable will continue to maintain the monostable time given by the resistors and capacitors at the beginning of the trigger edge, while the monostable will ignore the trigger signal after the flip. This chip can also be used as a multivibrator.

74HC123 monostable trigger. It has two inputs, A is valid for low level, B is valid for high level. There are two outputs, which are just opposite. Use external resistors and capacitors as timing elements, set the time by yourself, which is easier to use than the 74LS circuit. The monostable trigger 74HC123 and peripheral circuits realize this function. 74HC123 is a double-repeatable monostable. The width of its output pulse mainly depends on the timing resistor R and the timing capacitor C. The pulse width is calculated as the product of the capacitance value and the resistance value, that is, WP=R?C. In the actual design, R=5kW, C=80pF, the output pulse width is 400ns, and the amplitude is about 5V. The pulse fast edge amplification and emitter follower output circuit mainly accelerates and amplifies the shaped and widened trigger pulse, so as to obtain a pulse signal with a higher amplitude and a faster rising edge to trigger the field effect tube 2SC3306.

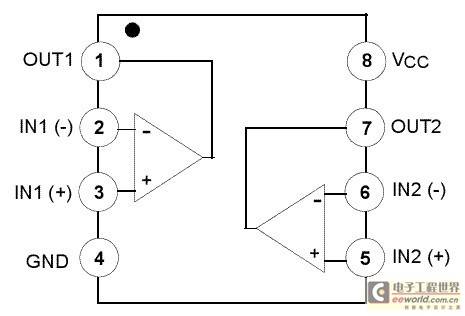

2.7 LM358

The LM358 includes two high-gain, independent, internally frequency-compensated dual op amps that are suitable for single power supplies with a wide voltage range, and are also suitable for dual power supply operation. Its application range includes sensor amplifiers, DC gain modules, and all other places where op amps can be used with a single power supply.

LM358 pin diagram and pin functions

The LM358 package has two types: plastic-sealed 8-lead dual in-line package and surface mount package.

Features of LM358:

. Internal frequency compensation

. Low input bias current

. Low input offset voltage and offset current

. Wide common-mode input voltage range, including ground

. Wide differential input voltage range, equal to the power supply voltage range

. High DC voltage gain (about 100dB)

. Unity gain bandwidth (approximately 1MHz)

. Wide power supply voltage range: single power supply (3-30V);

. Dual power supply (±1.5 to ±15V)

. Low power consumption, suitable for battery power supply

. Large output voltage swing (0 to Vcc-1.5V)

3. Hardware circuit installation and debugging

We encountered many problems during the hardware installation process. It was the first time to use the circuit board and we were not familiar with its internal connections, so many errors occurred.

The first step is to install the components and put them in the right position. The relationship between the two components should be well reflected on the circuit board, so that people can see it at a glance, and it should be beautiful and easy to connect the lines, and try to use the least amount of lines so that it does not look messy.

Then what needs to be done is to analyze the circuit diagram and wire the circuit board. The tools used include various pliers, tweezers, etc. For welding, solder is usually used as solder. It has good fluidity and adhesion. It has sufficient mechanical strength under certain temperature, humidity and vibration impact. It also has the advantages of corrosion resistance and easy use.

Flux: Its function is to remove oil stains, prevent the weldment from oxidation due to heat, and enhance the fluidity of solder.

Commonly used electric soldering irons include external heating, internal heating and rapid heating. Generally, the power should not be too large. If the power selected is too large, it is difficult to control the temperature, which can easily cause the component to overheat and be damaged.

The quality of solder joints is directly related to whether the entire circuit board can work properly, and it is also a basic skill that every operator must learn and master.

Welding sequence and method

First measure, make records, clean, tin, and finally check and measure.

Welding method:

1. Hold the soldering iron in your right hand. Use needle-nosed pliers or tweezers in your left hand to hold the component or wire. Before soldering, the soldering iron should be fully preheated. The blade of the soldering iron tip should be tinned and have a certain amount of solder.

2. Place the tip of the soldering iron close to the soldering point. The soldering iron should be at an angle of about 60 degrees to the horizontal plane. This will allow the molten tin to flow from the tip to the soldering point. The time the tip stays at the soldering point should be controlled to be 2 to 3 seconds.

3. Lift the soldering iron tip. Keep holding the component with your left hand. Wait until the tin at the soldering point cools and solidifies before releasing your left hand.

4. Use tweezers to turn the lead wire to make sure it is not loose, then use side cutting pliers to cut off the excess lead wire.

After the circuit is connected, debug it. The correct phenomenon is that the light turns on for a while and then turns off after the power is turned on. Cover the photoresistor, clap your hands, the light turns on, and then turns off after a few seconds. However, errors occurred during our design process: first, the circuit is short-circuited, the internal connection of the circuit board is not measured well, and the ground wires are not connected together.

Previous article:Design of 4-level intelligent dimmable fluorescent lamp electronic ballast circuit based on IRS2530D

Next article:Energy-saving and environmentally friendly light-controlled lighting

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- New breakthrough! Ultra-fast memory accelerates Intel Xeon 6-core processors

- New breakthrough! Ultra-fast memory accelerates Intel Xeon 6-core processors

- Consolidating vRAN sites onto a single server helps operators reduce total cost of ownership

- Consolidating vRAN sites onto a single server helps operators reduce total cost of ownership

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The difference between civilian-grade, industrial-grade and military-grade chips

- Silk screen 385 034T package SOP-8 power chip

- Development trends of automotive electronics, automotive integrated circuits, and automotive computing platforms

- My e-sports sharing + my little experience and suggestions

- Added performance test for STM32L432

- New predictions for cloud computing in 2019

- Typical applications of Zigbee technology in street light control systems

- Bluetooth BLE - BlueNRG2 VTimer

- Celebrate National Day and wish our motherland a happy 70th birthday!

- Automobile informatization: ITS becomes the fuse for the formation of a new industrial chain

Dual Radar: A Dual 4D Radar Multimodal Dataset for Autonomous Driving

Dual Radar: A Dual 4D Radar Multimodal Dataset for Autonomous Driving ICCV2023 Paper Summary: Vision, Graphics, and Robotics

ICCV2023 Paper Summary: Vision, Graphics, and Robotics

京公网安备 11010802033920号

京公网安备 11010802033920号