The author recently designed a standing wave indicator that uses 5 LED lights for display. This indicator uses radio frequency stealing, does not require power, is compact, light, and easy to carry, making it very suitable for amateur radio enthusiasts to use in the field. The directional coupler in the indicator circuit uses a three-magnetic ring structure that does not require debugging, uses a general-purpose operational amplifier as a comparator, and a proportional resistor network for standing wave ratio calibration, and uses different colored LEDs to indicate different standing wave ratio ranges. The entire circuit has no components that need to be adjusted, and it can work normally as long as the connection is correct. In the shortwave range, it can be used without any calibration and adjustment, which is very simple and convenient for enthusiasts to DIY.

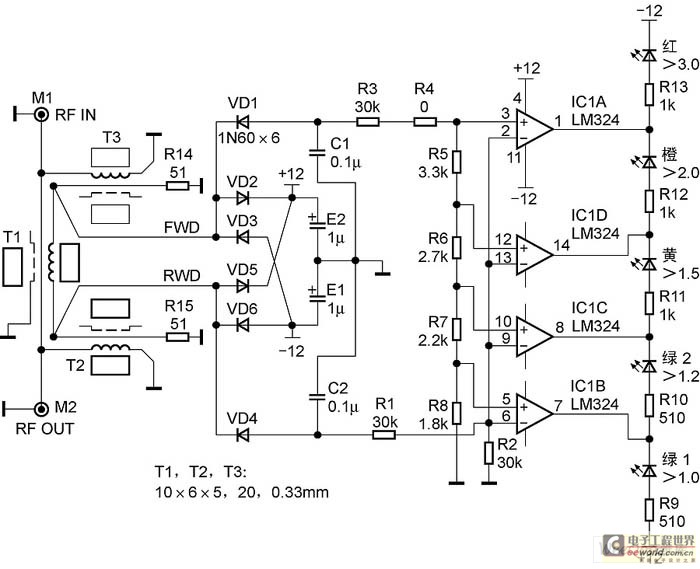

Figure 1 LED standing wave indicator circuit schematic

How it works

The schematic diagram of the LED standing wave indicator is shown in Figure 1. The circuit consists of three parts: a directional coupler, a standing wave ratio comparator, and an LED light display.

There are many kinds of directional couplers working in the shortwave band. Here, a three-magnetic ring structure that does not require debugging is selected. There are many articles introducing its working principle and production, which will not be repeated here.

The forward signal output by the directional coupler is sent to the voltage divider network composed of R3, R4, R5, R6, R7, and R8, and the corresponding voltage divider ratios of 1.2, 1.5, 2.0, and 3.0 are respectively given to the "+" inputs of the four operational amplifiers. The reverse signal output by the directional coupler is sent to the "-" inputs of the four operational amplifiers at the same time after being divided by R1 and R2.

The general-purpose op amps form four simple comparators. When the reflected signal exceeds the positive reference value of the corresponding standing wave ratio, the op amp outputs a voltage close to the positive power supply; when the reflected signal does not reach the positive reference value of the corresponding standing wave ratio, the op amp outputs a voltage close to the negative power supply. If indicator lights are connected to the output terminals of the four op amps, the four standing wave ratio ranges of >1.2, >1.5, >2.0, and >3.0 can be displayed. As long as the indicator light is lower than the maximum standing wave ratio, it will light up. However, this method is not conducive to the situation of RF power supply theft. The more lights are lit, the greater the current, and the RF loss will increase. In the actual circuit, the author adopted the LED connection method in the schematic diagram, and only lit up an LED corresponding to the standing wave ratio range, which increased the standing wave display and reduced the loss. The 5 LEDs are divided into 4 colors: 1.0~1.2 is green (I wanted to use blue, but the blue LED requires a high voltage to light up, and the minimum power requirement is correspondingly high, so I gave up), 1.2~1.5 is also green, 1.5~2.0 is $, 2.0~3.0 is orange, and 3.0 and above are red. In actual use, you can judge the size of the antenna standing wave by just looking at the color of the LED.

The operation of the operational amplifier and LED must have an appropriate power supply, which comes from the RF power stealing circuit. The RF power stealing circuit is composed of VD2, VD3, VD5, VD6, E1, and E2. This part of the circuit rectifies the forward and reverse signals from the three-magnetic ring directional coupler into positive and negative dual power supplies for the operational amplifier IC. The operational amplifier IC can operate in the range of ±1.5~±15V, and all operations are ratio operations, which have nothing to do with the absolute value of the voltage. Therefore, changes in the power supply voltage will not affect the calibration of the standing wave ratio, but will only have a greater impact on the brightness of the LED lamp. According to the changes in the brightness of the LED, we can also judge the changes in the RF power within a certain range.

Production process

The author installed the entire indicator in a standard aluminum alloy profile shielding box of 25mm×25mm×40mm, which has a compact structure.

The PCB I designed is double-sided, with components on both sides. Generally, the side with IC is soldered first. The corresponding components should be soldered according to the schematic diagram and the silk screen of the PCB, and there should be no cold soldering or short circuit. Then solder the 51Ω resistor and IN60 on the other side of the PCB, as shown in Figure 2.

Figure 2: Soldering IC on PCB

Bend the LED pins into right angles 1mm from the root, making sure the long leg is straight. After the LED pins are formed, solder the LEDs according to the required installation height (vertical length of the pins is 4.5mm), adjust them appropriately, and arrange them neatly, as shown in Figure 3.

Figure 3 The side of the PCB where the LED is soldered

Figure 4: Install the soldered PCB into the shielding box

Figure 5 Connectors installed at both ends of the shielding box

Install the soldered PCB into the shielding box, as shown in Figure 4. File off the plating and tin the parts behind the two SL16-KF head flanges, and install the connectors at both ends of the shielding box, as shown in Figure 5.

Open the back half of the shielding box, first solder the PCB and the tinned parts on the connector, then remove the front half of the shielding box, and solder the PCB on the LED lamp side and the tinned parts on the connector, as shown in Figure 6.

Figure 6 Solder the tinned parts of the PCB and the connector.

Use a 0.33mm diameter polyurethane enameled wire to wind 20 turns on a 10×6×5 nickel-zinc magnetic ring, 3 turns in total, with the winding direction consistent and even, and appropriate tightness, as shown in Figure 7. Take a 3cm 50-3 coaxial cable, cut it into shape as shown in the figure, and pass it through a magnetic ring, as shown in Figure 8.

Figure 7 Magnetic ring around finger

Figure 8 Passing the coaxial cable through the magnetic ring

Solder the three magnetic rings as shown in the schematic diagram and the figure. The cable shield can only be connected to the conductor outside the connector at one end. Use hot melt glue to fix the three magnetic rings. Put the shielding box back and fix the screws of the connector flange. A small and exquisite LED standing wave indicator is ready, see Figure 9.

Figure 9 Installed indicator circuit and appearance

test

As long as the assembly is correct, this standing wave indicator can be used normally. The IN terminal of the circuit is connected to the transmitter, and the OUT terminal is connected to the antenna or load. The light will be on when there is transmission (RF power>5W). In order to verify whether the standing wave ratio indication is correct, you can use a dummy load (SWR is 1.0) and some resistors, such as 68Ω (SWR about 1.3), 82Ω (SWR about 1.6), 30Ω (SWR about 1.7), 100Ω (SWR about 2.0), 16Ω (SWR about 3.2), etc. The power should be larger. You can also use multiple resistors in parallel, but not in series. Below 20MHz, the resistors of the general pins in parallel can reduce the influence of distributed inductance and improve high-frequency response, while series connection makes the frequency characteristics worse. If the indicator light is incorrect or the deviation is large, you need to open the shielding box, check carefully against the schematic diagram, and eliminate the error.

'

'

Figure 10: Actual measurement picture

Figure 10 shows some photos of the author's test. Actual tests show that the minimum LED lighting power is more than 5W, and the insertion loss is less than 0.3dB. Due to the small size and compact structure of this standing wave indicator, it is recommended that the maximum power does not exceed 50W. Its operating frequency can cover the short wave band and 6m band. If the coupler is well made, the high frequency end can exceed 160MHz.

Previous article:How to use LED as a photodiode

Next article:Research and design of heat dissipation issues of LED street lamps

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Will the GaN RF market be big?

- [RVB2601 Creative Application Development] 1 Unboxing and Environment Setup

- Practical tips on HGI MCU HC32L110

- Introduction to RF and Wireless Technology

- Help

- ODX-based diagnostic application software INTEWORK-OBT

- Share the MSP430F5529 clock UCS programming considerations

- RK3288 Information

- Occupy the posting position, ESP32---WS2812 16*16 dot matrix drawing points, lines and surfaces

- ASM1117 SOT-323 heat sink problem?

Follow me Season 2 Episode 1 All Codes

Follow me Season 2 Episode 1 All Codes Automobile LED lighting drive circuit design example

Automobile LED lighting drive circuit design example

京公网安备 11010802033920号

京公网安备 11010802033920号