High-end measuring instruments are composed of many electronic components. When the instrument is working, the heat generated by the electronic components gathers, causing the internal temperature of the instrument to rise, resulting in a decrease in the accuracy of the instrument. How do high-end measuring instruments solve the impact of temperature on their own accuracy?

Temperature affects the performance of electronic components

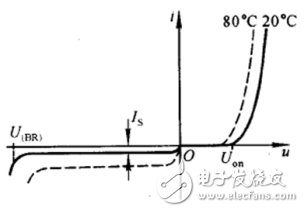

1. Impact on diode volt-ampere characteristics

When the ambient temperature rises, the forward characteristic curve of the diode will shift to the left, and the reverse characteristic curve will shift downward, as shown in Figure 1. Near room temperature, the forward voltage drop decreases by 2~2.5mV for every 1℃ increase in temperature; the reverse current increases by about one-fold for every 10℃ increase in temperature. It can be seen that the characteristics of the diode are very sensitive to temperature.

Figure 1. The volt-ampere characteristics of a diode

2. Impact on transistor input and output characteristics

Due to the thermal sensitivity of semiconductor materials, almost all parameters of transistors are related to temperature.

The influence of temperature on input characteristics: Similar to the diode volt-ampere characteristics, when the temperature rises, the positive offset will shift to the left, and vice versa, it will shift to the right, as shown in Figure 2.

The influence of temperature on output characteristics: As shown in Figure 3, the solid line and the dotted line are the characteristic curves at 20℃ and 60℃ respectively. It can be seen that when the temperature rises, the collector current increases due to the left shift of the input characteristics.

Figure 2 Effect of temperature on transistor output characteristics

Figure 3 Effect of temperature on transistor input characteristics

Stable static operating point suppresses temperature drift

Among the many factors that cause the instability of the static operating point, the influence of temperature on transistor parameters is the most important. The so-called stable static operating point and suppressed temperature drift usually means that when the ambient temperature changes, the static collector current and tube voltage drop of the transistor remain basically unchanged, and the change of the base electrode current must be relied upon to offset the change of the collector current. The commonly used method is to use DC negative feedback or temperature compensation to make the base current produce a change opposite to the collector current when the temperature changes.

Necessity of instrument preheating

Depending on the purpose and precision level of the instrument, some need to be preheated, while others do not. The preheating of the instrument is to achieve thermal stability and balance of the internal electronic components. It takes a certain amount of time for the capacitors, inductors, transistors, etc. in the circuit to reach a steady state, and preheating is necessary to reduce measurement errors. The more precise the instrument, the longer the preheating time.

How does ZHIYUAN Electronics power analyzer make the measurement results more accurate:

1. Before using the instrument, it needs to be preheated;

2. Before the measurement begins, a zero adjustment operation is required. Zero adjustment refers to the process of creating a state where the input signal is zero in the internal circuit of the power analyzer and setting the calculation result in this state to a zero level in a numerical sense;

3. Selecting the appropriate range, update rate and synchronization source is crucial to the measurement accuracy of the power analyzer. For example, when the update period is less than the period of the measured signal, as shown in Figure 4 below, the data within the entire update period becomes the measurement interval, and the sampled data within the entire update period will be averaged, thus affecting the accuracy of the measurement result. In this case, the update period needs to be increased so that the measured signal containing more periods enters the measurement interval;

Figure 4 Comparison of update cycles

4. Reduce the influence of stray capacitance on the measurement results. Since the instrument housing and the shielding box of the internal measurement circuit are insulated, there is stray capacitance between the two. Connecting the current measurement loop to the low voltage side, as shown in Figure 5, that is, connecting the current input terminal of the instrument to the end close to the ground potential of the power supply (Source), can effectively reduce the influence of stray capacitance on the measurement accuracy.

Figure 5 Wiring diagram

5. Reduce the impact of power loss. When measuring large currents, the voltage measurement loop needs to be connected to the side close to the load. The result measured by the current measurement loop is the sum of the currents flowing through the load and the voltage measurement loop. The measurement error is only the current flowing through the voltage measurement loop. When measuring small currents, the current measurement loop needs to be connected to the side close to the load. The result measured by the voltage measurement loop is the sum of the load voltage and the voltage of the current measurement loop. The measurement error is only the voltage at both ends of the current measurement loop; as shown in Figure 6.

Figure 6 Wiring diagram under different currents

At the same time, ZHIYUAN Electronics' PA power analyzer uses a high-stability temperature-compensated 100M synchronous clock to ensure the phase synchronization of ADC sampling of each channel, and the voltage and current phase error is within 10ns. In the module control unit of the host part, we use a high-stability temperature-compensated 100M synchronous clock. This clock signal will be sent to the ADC of each channel to ensure the ADC sampling phase synchronization. The voltage and current errors between single channels can be guaranteed to be within 10ns, reducing the error introduced by the instrument itself when measuring the U and I angles, and ensuring the accuracy of active power and power factor measurement! The industry has the problem that the power factor is too low or too low to be accurately measured, which has a lot to do with the error introduced by the instrument itself and the test method. Before the launch of ZHIYUAN Electronics' power analyzer, early instruments basically relied on post-calibration rather than hardware synchronization clock source, which is due to the advancement of electronic technology! As shown in Figure 7.

Figure 7 PA power analyzer architecture

Previous article:Design of filter analyzer based on LabWindows

Next article:Design of Audio Analyzer Based on LPC2148

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- In what situations are non-contact temperature sensors widely used?

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Download from the Internet--ARM Getting Started Notes

- Learn ARM development(22)

- Learn ARM development(21)

- Learn ARM development(20)

- Learn ARM development(19)

- Learn ARM development(14)

- Learn ARM development(15)

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- Jingzao Wireless Charging Mouse Pad Disassembly Report

- The data of the differential resistance sensor is fluctuating greatly, with about 11 bits fluctuating.

- TI - MCU - MSP430 User Guide 3 -> SYS System Control

- What parameters should be considered when changing a product from 422 communication to 485 communication?

- Looking for a chip that can output 1/3 or 1/2 input voltage and 1.5A current

- Is there anything you want to DIY now? What do you lack the most?

- 【Scene Reproduction Project Based on AI Camera】Project Submission

- bluenrg-2 cannot connect to other devices directly when it is the host

- Using STM32's MPU (Memory Protection Unit) to implement code isolation and access control

- FPGA embedded system design.part1.rar

Evaluating Roadside Perception for Autonomous Vehicles: Insights from Field Testing

Evaluating Roadside Perception for Autonomous Vehicles: Insights from Field Testing

京公网安备 11010802033920号

京公网安备 11010802033920号