In actual industrial production, pipeline electromagnetic flowmeter is one of the most commonly used flow measurement instruments. During the measurement signal sampling process of the electromagnetic flowmeter fluid medium, there will be various factors that affect the measurement data. The components of the interference signal are relatively complex, some are very strong, and sometimes even exceed the flow signal. How to eliminate these interference signals and improve the signal-to-noise ratio has always been a difficult problem in the installation and use of electromagnetic flowmeters, and is the key to the design and installation of electromagnetic flowmeters.

The electrode of the pipeline electromagnetic flowmeter is a metal substance. Although there are matching measuring electrodes for different media, the measured electrolyte liquid will undergo an electrochemical reaction when it contacts the metal electrode (that is, the process of electrode material corrosion, which is very common when the measured medium is salt, acid, or alkali liquid), and a polarization voltage will be generated on the electrode.

While the metal material of the measuring electrode undergoes an electrochemical reaction with the liquid medium, an oxide protective film will be produced on its surface to balance the electrochemical reaction. However, whenever a slurry fluid containing solid particles or fibers flows through the electrode, the solid particles will destroy the protective film on the electrode during the friction with the electrode, breaking the balance of the electrochemical reaction. The protective film will be re-formed on the measuring electrode surface. When the electrode repeats this process, a large polarization voltage will be generated on the electrode of the pipeline electromagnetic flowmeter, thus affecting the measured signal.

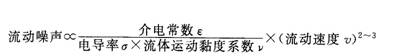

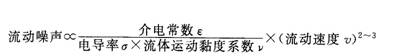

In another case, when we measure a very low conductivity fluid, a swinging DC polarization voltage will also appear. We call this phenomenon "flow noise" of low conductivity measurement. When the conductivity of the measured fluid is low to a certain extent, such as when the medium such as alcohol and pure water flows, the displacement current is not negligible, just like the movement of charges in a capacitor. The following formula can be used to approximately express the size of the flow noise. The flow friction lining surface of

the pipeline electromagnetic flowmeter fluid causes the charges near the electrode to follow the movement, so the changing polarization noise is induced on the electrode. Obviously, if the dielectric constant of the medium is high, the displacement current is large, the charges moving near the electrode also increase, and the flow noise increases with the increase of the dielectric constant E of the medium. According to the excitation frequency of the electromagnetic flowmeter, it may be between 100 and 400 Hz.

The DC interference potential often drifts randomly. The asymmetric DC interference potential of the two electrodes to the ground will convert the DC common mode voltage into a DC differential mode voltage. If the DC differential mode voltage amplitude is too large, it will cause the amplifier to block the pipeline electromagnetic flowmeter and destroy its linearity. In the converter measurement circuit, the capacitor isolation and sampling signal removal circuit can make the DC interference voltage output very small. In the actual application of the pipeline electromagnetic flowmeter, measures should also be taken to prevent the inner wall of the measured pipeline from being corroded by the pipeline electromagnetic flowmeter medium to produce a large potential difference. When this happens, we need to take timely measures to connect the front and rear metal pipes with equal potential to reduce the occurrence of DC interference potential and ensure the stability of the electromagnetic flowmeter measurement signal.

Reference address:Briefly describe the reasons for the generation of DC interference potential of pipeline electromagnetic flowmeter

The electrode of the pipeline electromagnetic flowmeter is a metal substance. Although there are matching measuring electrodes for different media, the measured electrolyte liquid will undergo an electrochemical reaction when it contacts the metal electrode (that is, the process of electrode material corrosion, which is very common when the measured medium is salt, acid, or alkali liquid), and a polarization voltage will be generated on the electrode.

While the metal material of the measuring electrode undergoes an electrochemical reaction with the liquid medium, an oxide protective film will be produced on its surface to balance the electrochemical reaction. However, whenever a slurry fluid containing solid particles or fibers flows through the electrode, the solid particles will destroy the protective film on the electrode during the friction with the electrode, breaking the balance of the electrochemical reaction. The protective film will be re-formed on the measuring electrode surface. When the electrode repeats this process, a large polarization voltage will be generated on the electrode of the pipeline electromagnetic flowmeter, thus affecting the measured signal.

In another case, when we measure a very low conductivity fluid, a swinging DC polarization voltage will also appear. We call this phenomenon "flow noise" of low conductivity measurement. When the conductivity of the measured fluid is low to a certain extent, such as when the medium such as alcohol and pure water flows, the displacement current is not negligible, just like the movement of charges in a capacitor. The following formula can be used to approximately express the size of the flow noise. The flow friction lining surface of

the pipeline electromagnetic flowmeter fluid causes the charges near the electrode to follow the movement, so the changing polarization noise is induced on the electrode. Obviously, if the dielectric constant of the medium is high, the displacement current is large, the charges moving near the electrode also increase, and the flow noise increases with the increase of the dielectric constant E of the medium. According to the excitation frequency of the electromagnetic flowmeter, it may be between 100 and 400 Hz.

The DC interference potential often drifts randomly. The asymmetric DC interference potential of the two electrodes to the ground will convert the DC common mode voltage into a DC differential mode voltage. If the DC differential mode voltage amplitude is too large, it will cause the amplifier to block the pipeline electromagnetic flowmeter and destroy its linearity. In the converter measurement circuit, the capacitor isolation and sampling signal removal circuit can make the DC interference voltage output very small. In the actual application of the pipeline electromagnetic flowmeter, measures should also be taken to prevent the inner wall of the measured pipeline from being corroded by the pipeline electromagnetic flowmeter medium to produce a large potential difference. When this happens, we need to take timely measures to connect the front and rear metal pipes with equal potential to reduce the occurrence of DC interference potential and ensure the stability of the electromagnetic flowmeter measurement signal.

Previous article:Solution for Changes in the Accuracy of Pipeline Electromagnetic Flowmeters

Next article:Several key points to pay attention to when purchasing domestic electromagnetic flowmeter products

- Popular Resources

- Popular amplifiers

Recommended Content

Latest Test Measurement Articles

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- In what situations are non-contact temperature sensors widely used?

MoreSelected Circuit Diagrams

MorePopular Articles

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

MoreDaily News

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Download from the Internet--ARM Getting Started Notes

- Learn ARM development(22)

- Learn ARM development(21)

- Learn ARM development(20)

- Learn ARM development(19)

- Learn ARM development(14)

- Learn ARM development(15)

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

Guess you like

- 2020 Share my thoughts on Qian'an, a national healthy and civilized county-level city

- MOS tube drain ringing

- [Pre-register to win a multimeter and JD card] Prize live broadcast | ADI's latest switches and multiplexers, technical parameters, design...

- Awesome, liquid metal circuit printing, fast plate making, no need to wait anymore~

- Current detection methods

- [CB5654 Intelligent Voice Development Board Review] Hardware Review

- FPGA Implementation of Floating-Point LMS Algorithm

- MPLABX Compilation Failure

- Selection of aluminum electrolytic capacitors

- EEWORLD University Hall ---- FanySkill Installation Instructions For Allegro 16.617.2 Version

TL081CP3

TL081CP3

京公网安备 11010802033920号

京公网安备 11010802033920号