Since the Italian scientist Spallanzani, who first discovered ultrasound in 1793, discovered the existence of ultrasound from bats, people have been more and more aware of and studied ultrasound. Because of the unique characteristics of ultrasound, ultrasonic sensors have increasingly reflected their importance in production and life. With the rapid advancement of science and technology today, ultrasonic sensors have been widely used in many fields of life and production and have played an important role. Through this article, readers can not only understand the difference between ultrasound and audible sound waves, understand the working principle of ultrasonic sensors, but also have a deeper understanding of the wide application of ultrasonic sensors (such as clamp-on ultrasonic flowmeters) in pipeline flow measurement, medical treatment, industrial production, liquid level measurement, ranging systems and other fields.

1. Overview of Ultrasonic Sensors

From the above, we can get the following characteristics of ultrasound: (1) Ultrasonic waves are highly directional when propagating and can be easily concentrated; (2) Ultrasonic waves can propagate in various media and can propagate over a sufficiently long distance; (3) The interaction between ultrasound and the sound-transmitting medium is moderate, and it is easy to carry information about the state of the sound-transmitting medium (diagnosis or effect on the sound-transmitting medium).

2. Working principle and structural composition of ultrasonic sensors.

Ultrasonic sensors are sensors developed using the characteristics of ultrasound. Using ultrasound as a means, ultrasound must be generated and received. The device that performs this function is an ultrasonic sensor, which is usually called an ultrasonic transducer or ultrasonic probe.

Ultrasonic probes are mainly composed of piezoelectric chips, which can both emit and receive ultrasound. The core of an ultrasonic probe is a piezoelectric chip in its plastic or metal jacket. The chip can be made of many materials. The main materials of ultrasonic sensors are piezoelectric crystals (electrostrictive) and nickel-iron-aluminum alloys (magnetostrictive). Electrostrictive materials include lead zirconate titanate (PZT) and the like. The ultrasonic sensor composed of piezoelectric crystals is a reversible sensor that can convert electrical energy into mechanical vibrations to generate ultrasonic waves. At the same time, when it receives ultrasonic waves, it can also convert them into electrical energy, so it can be divided into a transmitter and a receiver.

3. Practical application of ultrasonic sensors in production and life

1. Application of ultrasonic wave in pipeline flow measurement field

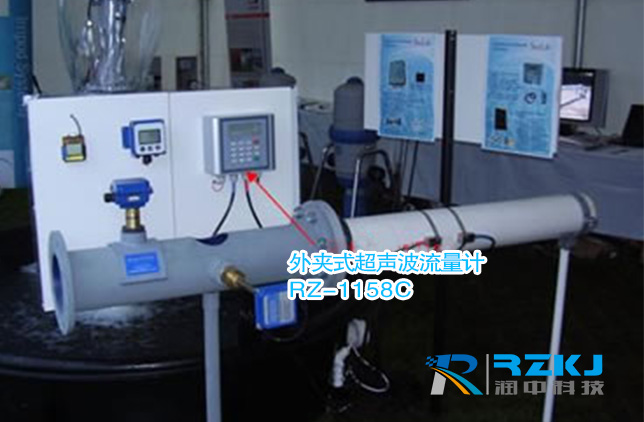

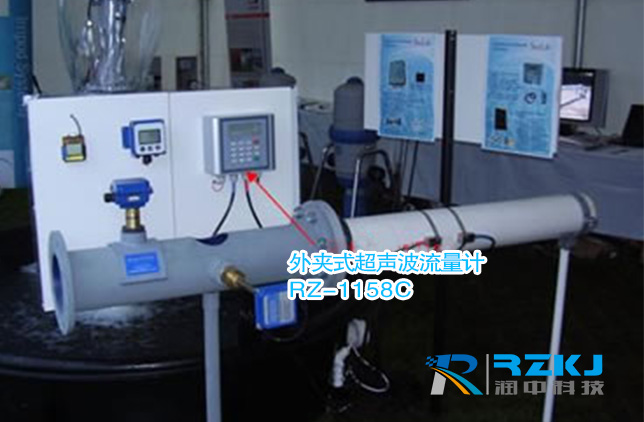

The clamp-on ultrasonic flowmeter adopts the time difference measurement principle: a probe transmits a signal through the pipe wall, the medium, and the other side of the pipe wall, and is received by another probe. At the same time, the second probe also transmits a signal and is received by the first probe. Due to the influence of the medium flow rate, there is a time difference Δt between the two. According to the calculation, the conversion relationship between the flow rate V and the time difference Δt can be obtained, V=(C2/2L)×Δt, and then the flow value Q can be obtained.

2. Application of ultrasonic distance sensor technology.

The ultrasonic sensor consists of three parts: ultrasonic transducer, processing unit and output stage. First, the processing unit excites the ultrasonic transducer with voltage, and it emits ultrasonic waves in the form of pulses after being excited. Then the ultrasonic transducer enters the receiving state. The processing unit analyzes the received ultrasonic pulse to determine whether the received signal is the echo of the emitted ultrasonic wave. If it is, the travel time of the ultrasonic wave is measured, and the measured time is converted into travel. Divided by 2, it is the distance of the object reflecting the ultrasonic wave. Install the ultrasonic sensor in a suitable position, aim at the direction of change of the object to be measured and emit ultrasonic waves, and the distance between the surface of the object and the sensor can be measured. Ultrasonic sensors have transmitters and receivers, but an ultrasonic sensor can also have the dual functions of transmitting and receiving sound waves. Ultrasonic sensors use the principle of piezoelectric effect to convert electrical energy and ultrasonic waves into each other, that is, when transmitting ultrasonic waves, electrical energy is converted to transmit ultrasonic waves; and when receiving echoes, ultrasonic vibrations are converted into electrical signals. 3. Application

of ultrasonic sensors in medicine.

The application of ultrasound in medicine is mainly to diagnose diseases, and it has become an indispensable diagnostic method in clinical medicine. The advantages of ultrasonic diagnosis are: no pain, no damage to the subject, simple method, clear imaging, high diagnostic accuracy, etc.

4. Application of ultrasonic sensors in measuring liquid level.

The basic principle of ultrasonic measurement of liquid level is: the ultrasonic pulse signal emitted by the ultrasonic probe propagates in the gas, encounters the interface between air and liquid and is reflected. After receiving the echo signal, the round-trip propagation time of the ultrasonic wave is calculated, and the distance or liquid level height can be converted. The ultrasonic measurement method has many advantages that other methods cannot match: (1) It does not have any mechanical transmission parts and does not contact the measured liquid. It is a non-contact measurement, not afraid of electromagnetic interference, not afraid of strong corrosive liquids such as acids and alkalis, etc., so it has stable performance, high reliability and long life; (2) Its short response time can be conveniently practiced for real-time measurement without lag.

5. Application of ultrasonic sensors in ranging systems.

There are roughly the following methods for ultrasonic distance measurement: 1. Take the average voltage of the output pulse. This voltage (its amplitude is basically fixed) is proportional to the distance. The distance can be measured by measuring the voltage; 2. Measure the width of the output pulse, that is, the time interval t between transmitting and receiving the ultrasonic wave. The measured distance is s=1/2vt. If the measured accuracy is very high, it should be corrected by temperature compensation. Ultrasonic distance is suitable for high-precision medium and long distance measurements.

IV. Conclusion of the article

This article discusses the principles and characteristics of ultrasonic sensors, and summarizes the wide application of ultrasonic sensors in various aspects of production and life, such as external clamp-on ultrasonic flowmeters for pipeline flow measurement. However, ultrasonic sensors also have their own shortcomings, such as emission problems, noise problems, etc. These related technical difficulties still need to be further optimized, and the related basic research supporting ultrasonic products still has room for further expansion and extension. Therefore, further research and study of ultrasonic sensors is still of great value.

Reference address:A brief analysis of the working principle of ultrasonic sensors and their applications in flow measurement and other fields

1. Overview of Ultrasonic Sensors

From the above, we can get the following characteristics of ultrasound: (1) Ultrasonic waves are highly directional when propagating and can be easily concentrated; (2) Ultrasonic waves can propagate in various media and can propagate over a sufficiently long distance; (3) The interaction between ultrasound and the sound-transmitting medium is moderate, and it is easy to carry information about the state of the sound-transmitting medium (diagnosis or effect on the sound-transmitting medium).

2. Working principle and structural composition of ultrasonic sensors.

Ultrasonic sensors are sensors developed using the characteristics of ultrasound. Using ultrasound as a means, ultrasound must be generated and received. The device that performs this function is an ultrasonic sensor, which is usually called an ultrasonic transducer or ultrasonic probe.

Ultrasonic probes are mainly composed of piezoelectric chips, which can both emit and receive ultrasound. The core of an ultrasonic probe is a piezoelectric chip in its plastic or metal jacket. The chip can be made of many materials. The main materials of ultrasonic sensors are piezoelectric crystals (electrostrictive) and nickel-iron-aluminum alloys (magnetostrictive). Electrostrictive materials include lead zirconate titanate (PZT) and the like. The ultrasonic sensor composed of piezoelectric crystals is a reversible sensor that can convert electrical energy into mechanical vibrations to generate ultrasonic waves. At the same time, when it receives ultrasonic waves, it can also convert them into electrical energy, so it can be divided into a transmitter and a receiver.

3. Practical application of ultrasonic sensors in production and life

1. Application of ultrasonic wave in pipeline flow measurement field

The clamp-on ultrasonic flowmeter adopts the time difference measurement principle: a probe transmits a signal through the pipe wall, the medium, and the other side of the pipe wall, and is received by another probe. At the same time, the second probe also transmits a signal and is received by the first probe. Due to the influence of the medium flow rate, there is a time difference Δt between the two. According to the calculation, the conversion relationship between the flow rate V and the time difference Δt can be obtained, V=(C2/2L)×Δt, and then the flow value Q can be obtained.

2. Application of ultrasonic distance sensor technology.

The ultrasonic sensor consists of three parts: ultrasonic transducer, processing unit and output stage. First, the processing unit excites the ultrasonic transducer with voltage, and it emits ultrasonic waves in the form of pulses after being excited. Then the ultrasonic transducer enters the receiving state. The processing unit analyzes the received ultrasonic pulse to determine whether the received signal is the echo of the emitted ultrasonic wave. If it is, the travel time of the ultrasonic wave is measured, and the measured time is converted into travel. Divided by 2, it is the distance of the object reflecting the ultrasonic wave. Install the ultrasonic sensor in a suitable position, aim at the direction of change of the object to be measured and emit ultrasonic waves, and the distance between the surface of the object and the sensor can be measured. Ultrasonic sensors have transmitters and receivers, but an ultrasonic sensor can also have the dual functions of transmitting and receiving sound waves. Ultrasonic sensors use the principle of piezoelectric effect to convert electrical energy and ultrasonic waves into each other, that is, when transmitting ultrasonic waves, electrical energy is converted to transmit ultrasonic waves; and when receiving echoes, ultrasonic vibrations are converted into electrical signals. 3. Application

of ultrasonic sensors in medicine.

The application of ultrasound in medicine is mainly to diagnose diseases, and it has become an indispensable diagnostic method in clinical medicine. The advantages of ultrasonic diagnosis are: no pain, no damage to the subject, simple method, clear imaging, high diagnostic accuracy, etc.

4. Application of ultrasonic sensors in measuring liquid level.

The basic principle of ultrasonic measurement of liquid level is: the ultrasonic pulse signal emitted by the ultrasonic probe propagates in the gas, encounters the interface between air and liquid and is reflected. After receiving the echo signal, the round-trip propagation time of the ultrasonic wave is calculated, and the distance or liquid level height can be converted. The ultrasonic measurement method has many advantages that other methods cannot match: (1) It does not have any mechanical transmission parts and does not contact the measured liquid. It is a non-contact measurement, not afraid of electromagnetic interference, not afraid of strong corrosive liquids such as acids and alkalis, etc., so it has stable performance, high reliability and long life; (2) Its short response time can be conveniently practiced for real-time measurement without lag.

5. Application of ultrasonic sensors in ranging systems.

There are roughly the following methods for ultrasonic distance measurement: 1. Take the average voltage of the output pulse. This voltage (its amplitude is basically fixed) is proportional to the distance. The distance can be measured by measuring the voltage; 2. Measure the width of the output pulse, that is, the time interval t between transmitting and receiving the ultrasonic wave. The measured distance is s=1/2vt. If the measured accuracy is very high, it should be corrected by temperature compensation. Ultrasonic distance is suitable for high-precision medium and long distance measurements.

IV. Conclusion of the article

This article discusses the principles and characteristics of ultrasonic sensors, and summarizes the wide application of ultrasonic sensors in various aspects of production and life, such as external clamp-on ultrasonic flowmeters for pipeline flow measurement. However, ultrasonic sensors also have their own shortcomings, such as emission problems, noise problems, etc. These related technical difficulties still need to be further optimized, and the related basic research supporting ultrasonic products still has room for further expansion and extension. Therefore, further research and study of ultrasonic sensors is still of great value.

Previous article:Analysis of solutions to effectively improve the ultrasonic flowmeter's ability to resist external noise interference

Next article:Overview of the advantages of ultrasonic flowmeters and actual cases of flow measurement in power plants

Recommended Content

Latest Test Measurement Articles

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

MoreSelected Circuit Diagrams

MorePopular Articles

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

MoreDaily News

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

Guess you like

- Notes on programming the Hezhongda DM6446 development board

- IMX6 development board creates the first Android application HelloWorld

- Why does the cell phone turn off as soon as it rings?

- PADS9.5 installation package

- Please help me find out what microcontroller this is

- MicroPython Hands-on (37) - Driving LCD and Graphic Display

- This video gives you a feel of what it feels like to be surrounded by the Earth

- FPGA Implementation of 32-bit Single-precision Floating-point Multiplier

- A question about the data sheet

- TI low-power wireless charging solution

Signal Integrity and Power Integrity Analysis (Eric Bogatin)

Signal Integrity and Power Integrity Analysis (Eric Bogatin)

京公网安备 11010802033920号

京公网安备 11010802033920号