This article summarizes:

Reference address:Application characteristics and diameter reduction processing methods of electromagnetic flowmeters in water supply industry

With the advancement of China's urbanization process, the construction scale of industrial water supply and urban water supply has continued to increase, and higher requirements have been put forward for the relevant water supply infrastructure. As an important part of water supply equipment, electromagnetic flowmeter not only monitors the calculation of water supply production efficiency, but also plays a key role in the trade settlement of water supply departments to downstream. As a flow measurement device, electromagnetic flowmeter can be used in many industrial production sites. According to the characteristics of the water supply industry, electromagnetic flowmeters are also different from other places of use in selection, installation and use. This article will explain the characteristics of the use of electromagnetic flowmeters in the water supply industry and the diameter reduction treatment method during installation:

Characteristics of electromagnetic flowmeters in the water supply industry:

Characteristics of electromagnetic flowmeters in the water supply industry:

1. High accuracy requirement: Measurement data is used for trade settlement, and the measurement accuracy requirement is high. According to GB/T17167, the accuracy should reach ±2.5%R. For large-caliber meters, some users require up to ±0.5%R.

2. Small measurement resistance: The flow meter installed on the raw water and tap water main pipeline has a large diameter to reduce pumping costs and requires small resistance.

3. High requirements for measurement conditions: high requirements for measurement range. Household users use water intermittently, and even large enterprises and institutions have very different water consumption between day and night, between different seasons, and in different stages of production, operation, management or service.

4. High requirements for external protection: The environment is harsh, and large-diameter pipelines are usually buried. Therefore, most flow meters are installed in instrument wells. If you are not careful, rainwater will flood the instrument. Therefore, the flow meter should have IP68 environmental protection capabilities.

5. Easy to handle dirty pipes: The cleanliness of raw water is poor, and the pressure is not high. Under the condition of low-speed flow in large-diameter pipes, silt is easy to accumulate on the pipe wall, so the design and selection of instruments should consider the impact of silt, and the cleaning of silt should be considered during engineering design and installation.

According to the above characteristics, the current opinions on instrument selection tend to be consistent. For large-diameter flowmeters used for trade settlement, electromagnetic flowmeters are most suitable, which can fully meet the above requirements. Rotor-type water meters are used for small-diameter water flow measurement. Treatment method of

electromagnetic flowmeter diameter change:

According to the above characteristics, the current opinions on instrument selection tend to be consistent. For large-diameter flowmeters used for trade settlement, electromagnetic flowmeters are most suitable, which can fully meet the above requirements. Rotor-type water meters are used for small-diameter water flow measurement. Treatment method of

electromagnetic flowmeter diameter change:

We all know that the measurement principle of electromagnetic flowmeter is Faraday's law of electromagnetic induction. It is mainly used to measure the volume flow of conductive liquids and slurries in closed pipes. After years of actual operation and observation and comparative analysis, we believe that electromagnetic flowmeter is superior to other metering instruments in the field of water supply metering. In actual applications, it is often the case that the water flow velocity in the pipe is low due to the nature of the user's water, which cannot meet the requirements of the electromagnetic flowmeter for the flow velocity range, so at this time, the pipe needs to be reduced in diameter.

The specific method is to select the diameter of pipes, pipe fittings and valves according to the parameters after the system is combined, and then select an electromagnetic flowmeter with a smaller sensor diameter than the measured pipe diameter. In other words, the pipe diameter of the measured pipe is inconsistent with the meter diameter of the electromagnetic flowmeter. The pipe diameter is large and the meter diameter is small. When installing and connecting, add a reducer before and after the sensor. The result of this is that the flow velocity is increased in the local pipeline where the electromagnetic flowmeter is installed, meeting the flowmeter's requirements for the flow velocity range.

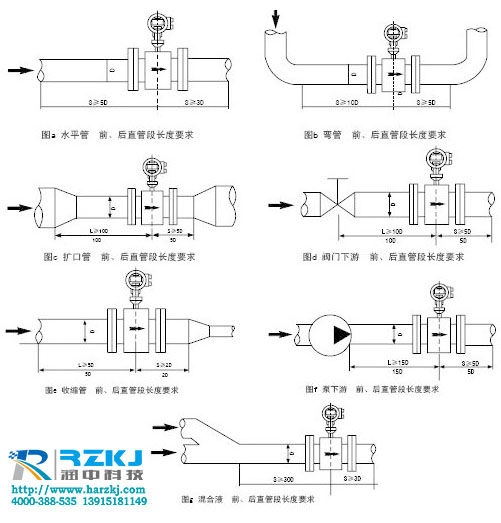

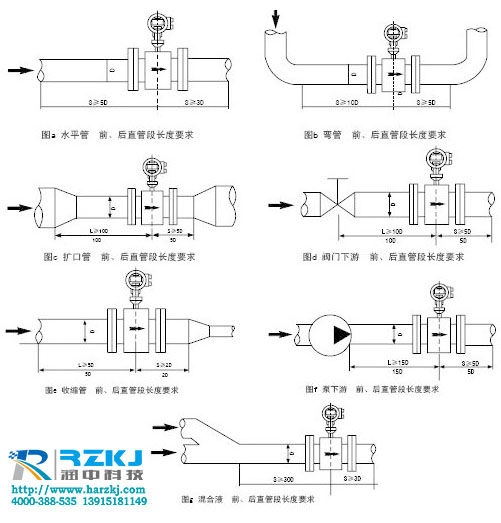

When performing the diameter reduction process, it is important to note that the reducer must meet the taper requirements. The inlet and outlet straight pipe sections of the electromagnetic flowmeter have length requirements. If the reducers added before and after the sensor are to be considered as part of the straight pipe section, they must meet the product's requirements that the tapered angle of the pipe sections before and after the sensor should be less than 15°. When the reducer cannot meet the taper requirements, an extended expanding or contracting pipe must be ordered.

When electromagnetic flowmeter is used for water supply metering, because its sensor has flow rate requirements, but the flow rate range is wide, the designer can make some flexible changes according to the user's water consumption and the actual situation on site, which not only saves the investment of water meter group, but also enables the flowmeter to operate in a better working state. By the way, the upstream side of the electromagnetic flowmeter should have a straight pipe section of no less than 5D times the pipe diameter, and the downstream side should have a straight pipe section of no less than 3 times the inner diameter of the pipe. If there is a non-fully open gate valve or regulating valve upstream, the length of the upstream straight pipe section of the flowmeter should be increased to 10 times the inner diameter of the pipe.

Previous article:Why is there a lining inside the electromagnetic flowmeter?

Next article:Introduction to the most common types of electromagnetic flowmeter lining materials

- Popular Resources

- Popular amplifiers

Recommended Content

Latest Test Measurement Articles

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- In what situations are non-contact temperature sensors widely used?

- How non-contact temperature sensors measure internal temperature

MoreSelected Circuit Diagrams

MorePopular Articles

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

MoreDaily News

- CGD and Qorvo to jointly revolutionize motor control solutions

- CGD and Qorvo to jointly revolutionize motor control solutions

- Keysight Technologies FieldFox handheld analyzer with VDI spread spectrum module to achieve millimeter wave analysis function

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- A new chapter in Great Wall Motors R&D: solid-state battery technology leads the future

- Naxin Micro provides full-scenario GaN driver IC solutions

- Interpreting Huawei’s new solid-state battery patent, will it challenge CATL in 2030?

- Are pure electric/plug-in hybrid vehicles going crazy? A Chinese company has launched the world's first -40℃ dischargeable hybrid battery that is not afraid of cold

Guess you like

- [FM33LG0 series development board evaluation] 02. Basic engineering (LED, KEY, LPUART, LPTIM, SHELL)

- TMS320F28027F for power stage control

- [TI recommended course] #DC/DC switching regulator packaging innovation#

- How to set BGA area ROOM rules in Altium Designer

- How to choose E907 boot mode for Allwinner V853 under Tina

- How to isolate power modules and non-isolated power supplies respectively

- High Voltage Impedance Tuning Quick Guide

- Will 5G really bring about big changes?

- Today I suddenly thought of this: If resistors of the same resistance are first connected in series and then in parallel, what is the resistance after N?

- Let’s talk about high technology today… Why is a chip so difficult to make?

9216501MPA

9216501MPA

京公网安备 11010802033920号

京公网安备 11010802033920号