Home >

Communication Circuits >Wireless Reception > Circuit principle and production of six-tube radio

Circuit principle and production of six-tube radio

Source: InternetPublisher:拳制龙 Keywords: Radio Circuit Updated: 2024/11/15

The six-tube radio is a medium-band AM pocket-sized semiconductor radio. The frequency coverage range is 535-1605kHz, and the output power is 50mW without distortion and 150mW at maximum.

1. Circuit composition and functions of each circuit

The circuit composition of this radio is shown in the figure below. It mainly includes receiving circuit, high frequency amplification and frequency conversion circuit, intermediate frequency amplification, detection, audio amplification (including power amplification), etc. The functions of each circuit are as follows.

1. The receiving

circuit is composed of a magnetic bar coil L1 and a variable capacitor C1a connected in series.

When the receiving circuit resonates in series with the frequency signal of the airborne radio station, the current in the circuit is the largest. This signal can be coupled to the frequency conversion stage through L2 for processing, while the radio signal that does not resonate is suppressed and cannot enter the radio. Therefore, the receiving circuit is also called a station selection circuit.

2.

The radio signal selected by the receiving circuit is coupled to the base of VT1 through L2, and after amplification and frequency conversion with the local oscillation signal input from its emitter, the intermediate frequency signal (f本-f和=f中=465kHz) is selected by the intermediate frequency resonator B3 connected in series in the collector and sent to the next intermediate frequency amplifier.

3. The two intermediate frequency amplifiers VT2 and VT3

further select and amplify the intermediate frequency signal.

4. The detection circuit

is completed by the nonlinearity and low-pass filtering of VT3. Its function is to detect the audio modulation signal (useful signal), remove the intermediate frequency carrier signal, and then send the audio signal to the volume potentiometer W through the resistor R6. Then it is sent to the base of the preamplifier VT4 through the capacitor C8. Capacitors C5 and C6 are bypass capacitors for the intermediate frequency signal.

5. The audio preamplifier

VT4 is an audio preamplifier. Its function is to amplify the input audio signal and use the secondary of the input transformer to divide it into two groups of signals with opposite polarities to input the push-pull power amplifier.

6. The audio power amplifier

is composed of VT5 and VT6 to form a push-pull power amplifier. Among them, vT5 amplifies the positive half cycle of the audio signal, VT6 amplifies the negative half cycle of the audio signal, and uses the secondary of the output transformer to combine the positive and negative half cycles of the audio signal to drive the speaker to sound.

2. Selection and testing of circuit components

This is an important step to ensure the quality of the whole machine. Only when the components are qualified products can a good quality radio be assembled.

1. Resistors and potentiometers

This machine has a total of 8 color ring resistors and 1 potentiometer.

(1) Color ring resistors

The resistors used in this machine are four-ring color ring resistors. The last ring is gold or silver, which is the error ring. The remaining three rings are resistance rings. The number represented by the first color ring is the first significant digit of the resistance value, the number represented by the second color ring is the second significant digit of the resistance value, and the number represented by the third color ring is the resistance value multiplied by 10n (n is the number represented by the color J.

The fourth color ring represents the error of the component, and the unit of resistance is ohm. The color code symbol regulations are shown in the table below.

This is an important step to ensure the quality of the whole machine. Only when the components are qualified products can a good quality radio be assembled.

1. Resistors and potentiometers

This machine has a total of 8 color ring resistors and 1 potentiometer.

(1) Color ring resistors

The resistors used in this machine are four-ring color ring resistors. The last ring is gold or silver, which is the error ring. The remaining three rings are resistance rings. The number represented by the first color ring is the first significant digit of the resistance value, the number represented by the second color ring is the second significant digit of the resistance value, and the number represented by the third color ring is the resistance value multiplied by 10n (n is the number represented by the color J.

The fourth color ring represents the error of the component, and the unit of resistance is ohm. The color code symbol regulations are shown in the table below.

Representative significance | silver | gold | black | Brown | red | orange | yellow | green | blue | purple | Ash | white | none |

Significant Figures | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |||

Multiplier (order of magnitude) | 10/-2 square) | 10/-01 | 10/0 | 10/(1st power | 10/2 | 10/3 | 10/4 | 10/5th power) | 10/6 | 10/7 | 10/8 | 10/9 | |

Resistance tolerance (%) | ±10 | ±5 | ±20 |

For example: the ring color is red, yellow, orange, and gold, and the resistance is 24x103 (±5%), that is, 24kΩ, and the error is ±5%. Another example is that the ring color is green, brown, black, and silver, and the resistance is 51×10° (±10%), that is, 51Ω, and the error is ±10%.

Read the resistor value according to the color ring and verify it with the resistance block of the multimeter. Pin them on white paper in order and mark the resistance value on the side for easy access during installation. "*" is the symbol of the undetermined resistor.

(2) The potentiometer

should be a potentiometer with a switch. There are 5 pins on it, the two wider pins are switches, and the other 3 narrower pins are the 3 pins of the variable resistor. The two sides are the fixed ends of the resistor, and the middle terminal is the movable end of the resistor. During the test, turn the multimeter to the resistance block, use the resistance × 100 block, connect one probe to the middle movable end, and the other probe to the two fixed ends respectively. When the shaft is rotated, the resistance value should change continuously from 0 to 5kΩ or from 5 to 0kΩ. The middle needle cannot move, indicating that the potentiometer is intact.

2. Capacitors and double-connected variable capacitors

This machine has a total of 7 non-polar capacitors and 1 double-connected variable capacitor.

For non-polar capacitors with a capacitance less than 1μF, the resistance value between the two pins can be measured with the 1k block of the multimeter. The two movable plates of the double-connected capacitor are connected together and grounded. Use the 1k block of the multimeter, connect one probe to the middle lead, and the other probe to the pins of the fixed plate. Rotate the shaft, and the pointer of the multimeter should stop at the position of infinite resistance and not move, indicating that the variable capacitor has no touching phenomenon, so it can be applied.

In addition, for polar capacitors with larger capacitance, the multimeter resistance is 1k block, the black probe is connected to the positive pole (long pin) of the capacitor, and the red probe is connected to the negative pole (short pin) of the capacitor. The needle should swing to the right at a certain angle, and then swing to the left to the infinite position.

This machine has a total of 7 non-polar capacitors and 1 double-connected variable capacitor.

For non-polar capacitors with a capacitance less than 1μF, the resistance value between the two pins can be measured with the 1k block of the multimeter. The two movable plates of the double-connected capacitor are connected together and grounded. Use the 1k block of the multimeter, connect one probe to the middle lead, and the other probe to the pins of the fixed plate. Rotate the shaft, and the pointer of the multimeter should stop at the position of infinite resistance and not move, indicating that the variable capacitor has no touching phenomenon, so it can be applied.

In addition, for polar capacitors with larger capacitance, the multimeter resistance is 1k block, the black probe is connected to the positive pole (long pin) of the capacitor, and the red probe is connected to the negative pole (short pin) of the capacitor. The needle should swing to the right at a certain angle, and then swing to the left to the infinite position.

3. Antenna coil, local oscillator coil, intermediate frequency transformer and input/output transformer

(1) Antenna coil

The antenna coil is a set of two coils wound on the magnetic rod with enameled wire through a nylon sheet as shown in the figure on the right. The purpose of the nylon sheet is to enable the coil to move on the magnetic rod. When measured with the resistance block of a multimeter, there should be a path between pins 1 and 2, and a path between pins 3 and 4 (the paint on the lead head should be scraped off and tinned).

(2) Local oscillator coil

B2 is a local oscillator coil, and its size is the same as that of the intermediate frequency. The number of pins is exactly the same. There is a path between pins 1, 2, and 3 of the local oscillator coil, which is a coil with a middle tap. There should be a path between pins 4 and 5, which is a coil.

(3) Intermediate frequency transformer

B3 and B4 are intermediate frequency transformers, and there should be a path between pins 1 and 2, and there should be a path between pins 3, 4, and 5. The difference from the local oscillator coil is that there is a capacitor installed at the bottom, and its schematic diagram is shown in the figure below.

(4) Input and output transformers

B5 and B6 are input and output transformers. Their appearance, size and pin arrangement are exactly the same. Among them, pins 1 and 2 are a coil, which should be a passage; pins 3, 4, and 5 are coils with center taps, which should be a passage. The schematic diagram is shown below. The main difference between the input and output transformers is that the resistance value (number of turns) between pins 1 and 2 is different. The resistance value of the input transformer is larger, and the resistance value of the output transformer is smaller (measured with R×10 block).

B5 and B6 are input and output transformers. Their appearance, size and pin arrangement are exactly the same. Among them, pins 1 and 2 are a coil, which should be a passage; pins 3, 4, and 5 are coils with center taps, which should be a passage. The schematic diagram is shown below. The main difference between the input and output transformers is that the resistance value (number of turns) between pins 1 and 2 is different. The resistance value of the input transformer is larger, and the resistance value of the output transformer is smaller (measured with R×10 block).

4. Crystal transistors and diodes

VTI, VT2, VT3, VT4, and VT5 are NPN crystal transistors. Their appearance and pin arrangement are exactly the same. The pins are identified as follows: facing the plane of the model, the left pin is the emitter e, the middle pin is the base b, and the right pin is the collector C.

The method of using the ohm range (1k range) of the multimeter to measure its amplification ability is: the black test lead (positive battery) is connected to the transistor C. The red test lead (negative battery) is connected to e. At this time, the needle does not move, and then a resistance of about 100kΩ is connected between the C pole and the base b. At this time, the pointer swings to the right at an angle, indicating that the transistor has amplification ability. Under the same conditions, the greater the angle of the pointer swinging to the right, the stronger the amplification ability.

VD is a crystal diode. Using the ohm 1k range to measure its resistance value, the resistance value in one direction is large (or small), and the resistance value in the other direction is small (or large). The one with a small resistance value, the black test lead is connected to the positive pole of the diode. The end of the crystal diode used in this machine with a black ring is its cathode.

VTI, VT2, VT3, VT4, and VT5 are NPN crystal transistors. Their appearance and pin arrangement are exactly the same. The pins are identified as follows: facing the plane of the model, the left pin is the emitter e, the middle pin is the base b, and the right pin is the collector C.

The method of using the ohm range (1k range) of the multimeter to measure its amplification ability is: the black test lead (positive battery) is connected to the transistor C. The red test lead (negative battery) is connected to e. At this time, the needle does not move, and then a resistance of about 100kΩ is connected between the C pole and the base b. At this time, the pointer swings to the right at an angle, indicating that the transistor has amplification ability. Under the same conditions, the greater the angle of the pointer swinging to the right, the stronger the amplification ability.

VD is a crystal diode. Using the ohm 1k range to measure its resistance value, the resistance value in one direction is large (or small), and the resistance value in the other direction is small (or large). The one with a small resistance value, the black test lead is connected to the positive pole of the diode. The end of the crystal diode used in this machine with a black ring is its cathode.

3. Assembly of the whole machine

1. Installation principle

The general installation principle is to install components (resistance, capacitance, voltage) first and then devices, small first and then large, short first and then tall, light first and then heavy. If the distance between the two pads is greater than the length of the component body, use horizontal installation, and if it is less than the length of the component body, use vertical installation.

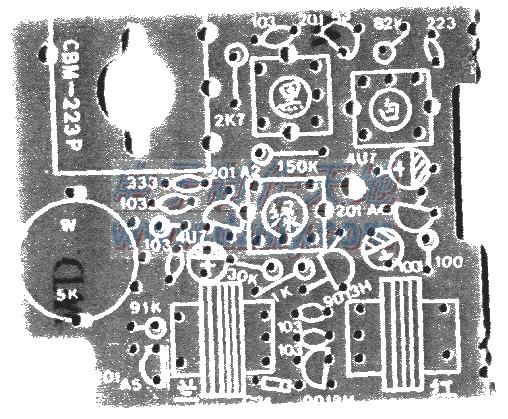

2. Processing of printed circuit boards

Because printed circuit boards are generally stored for a long time, the pads will oxidize and are not easy to weld. This requires applying flux, that is, rosin water, to the pads. The method of making rosin water is: soak the rosin block or foam in alcohol and wait for it to completely dissolve. The printed circuit board circuit is shown in the figure below.

The general installation principle is to install components (resistance, capacitance, voltage) first and then devices, small first and then large, short first and then tall, light first and then heavy. If the distance between the two pads is greater than the length of the component body, use horizontal installation, and if it is less than the length of the component body, use vertical installation.

2. Processing of printed circuit boards

Because printed circuit boards are generally stored for a long time, the pads will oxidize and are not easy to weld. This requires applying flux, that is, rosin water, to the pads. The method of making rosin water is: soak the rosin block or foam in alcohol and wait for it to completely dissolve. The printed circuit board circuit is shown in the figure below.

3. Installation of components

According to the installation principle, install the resistors that do not need to be adjusted first. Horizontal resistors should be close to the printed circuit board, and the resistor body should be in the middle of the two welding holes; the direction of the color ring should be arranged as consistent as possible. For vertical resistors, the error ring should face downward, and the other leg should be bent into an arc and parallel to the resistor body before inserting into the two pads. Then, after checking that there is no error, solder it and cut off the excess pins.

Secondly, plug in the non-polar capacitor, the lower the better, and then plug in the electrolytic capacitor. Pay attention to the polarity not to be inserted incorrectly (the long leg is positive and the short leg is negative). It must be inserted to the bottom to avoid being too high and not being able to cover the box cover. After checking that there is no error, solder and cut off the excess pins.

Then plug in the double-connected capacitor (fix it with the antenna nylon frame with screws), volume potentiometer, local oscillator coil, two intermediate circuits, input, input transformer, diode vD, and solder after checking that there is no error, and cut off the excess pins.

After the above components are installed, check again to ensure that there is no error connection, no cold soldering, and no overlap. Finally, install the transistor, and be careful not to connect the three electrodes of the transistor incorrectly.

4. Debugging of the whole machine

1. Adjust the static working point of the transistor (i.e. adjust the bias current).

The transistors in each level of the radio circuit should work at a certain static working point. Whether the working point is appropriate can be measured by the current value indicated by the ammeter connected to the collector circuit. Connect the ammeter in series to the point marked with an X in the circuit (see the figure below), and the current value indicated by the needle is the collector current value. Under normal circumstances, lc, -0.4mA, IC2-0.9mA, lc3-1mA, Ic4-1.5mA, lc5&6: -2-5mA.

When adjusting. Connect the DC ammeter in series to the collector circuit to be adjusted, and then adjust the bias resistance of its base. The method used is: connect a potentiometer to the bias resistor position (the resistance of the potentiometer is close to the resistance value to be determined, and it must be connected in series with a fixed resistor of half the resistance value to be determined), and adjust the resistance of the potentiometer to the maximum. Then connect the DC power supply and see the indication of the ammeter. If the current value is less than the normal value of the level, reduce the value of the potentiometer until it is adjusted to the specified value. If the indication of the ammeter is greater than the normal value of the level after the power supply is connected, then you need to change a potentiometer with a larger resistance value for debugging until it is adjusted to the normal value. Then remove the potentiometer after it is adjusted to the normal value, measure its resistance value with a resistance block, and finally select a fixed resistor with a resistance value very close to its resistance value and weld it to the position of the resistance to be determined, and then turn on the power to see the collector current. If the change is not large, it meets the requirements. After

the static operating point current of each level is adjusted to the required value, the metal part of the small screwdriver in the hand touches the center end (active end) of the volume potentiometer. If the speaker makes a "click" sound, it means that the low-level circuit of the radio is normal; if you can't hear the "click" sound, you need to further debug the static operating point of the low-level circuit until you hear the "click" sound.

Then hold the metal part of the screwdriver and touch the base of VT3, and the speaker sound should be further increased than before. Use the same method to touch the base of VT2, and the speaker will sound louder. Use the same method to touch the base of VT1, and the speaker should sound the loudest. This means that the DC working state of the radio is basically normal.

At this time, rotating the double-connected shaft can generally receive the radio audio signal.

The transistors in each level of the radio circuit should work at a certain static working point. Whether the working point is appropriate can be measured by the current value indicated by the ammeter connected to the collector circuit. Connect the ammeter in series to the point marked with an X in the circuit (see the figure below), and the current value indicated by the needle is the collector current value. Under normal circumstances, lc, -0.4mA, IC2-0.9mA, lc3-1mA, Ic4-1.5mA, lc5&6: -2-5mA.

When adjusting. Connect the DC ammeter in series to the collector circuit to be adjusted, and then adjust the bias resistance of its base. The method used is: connect a potentiometer to the bias resistor position (the resistance of the potentiometer is close to the resistance value to be determined, and it must be connected in series with a fixed resistor of half the resistance value to be determined), and adjust the resistance of the potentiometer to the maximum. Then connect the DC power supply and see the indication of the ammeter. If the current value is less than the normal value of the level, reduce the value of the potentiometer until it is adjusted to the specified value. If the indication of the ammeter is greater than the normal value of the level after the power supply is connected, then you need to change a potentiometer with a larger resistance value for debugging until it is adjusted to the normal value. Then remove the potentiometer after it is adjusted to the normal value, measure its resistance value with a resistance block, and finally select a fixed resistor with a resistance value very close to its resistance value and weld it to the position of the resistance to be determined, and then turn on the power to see the collector current. If the change is not large, it meets the requirements. After

the static operating point current of each level is adjusted to the required value, the metal part of the small screwdriver in the hand touches the center end (active end) of the volume potentiometer. If the speaker makes a "click" sound, it means that the low-level circuit of the radio is normal; if you can't hear the "click" sound, you need to further debug the static operating point of the low-level circuit until you hear the "click" sound.

Then hold the metal part of the screwdriver and touch the base of VT3, and the speaker sound should be further increased than before. Use the same method to touch the base of VT2, and the speaker will sound louder. Use the same method to touch the base of VT1, and the speaker should sound the loudest. This means that the DC working state of the radio is basically normal.

At this time, rotating the double-connected shaft can generally receive the radio audio signal.

2. Adjust the intermediate frequency (adjust the intermediate frequency)

The purpose is to adjust the resonant frequency of the two intermediate frequencies to a fixed intermediate frequency of 465kHz. When adjusting the intermediate frequency, use a non-inductive screwdriver (a small flat-blade screwdriver made of bamboo strips, waste toothbrush handles, hard plastic sheets or bakelite sheets) to adjust the intermediate frequency core. It is not advisable to use a metal screwdriver, because metal screwdrivers are prone to human body induction and inaccurate adjustment.

The adjustment method is: turn on the radio and listen to a radio station at random, then use a wire or a screwdriver to short-circuit the double-connected oscillation stator (that is, use a wire, one end is grounded, and the other end touches the oscillation stator). If the sound disappears immediately or weakens significantly, it means that the frequency conversion stage and the local oscillation circuit are both working. If there is no effect on the sound, it means that the local oscillation is not working, and the signal is passed through the intermediate amplifier stage. At this time, the adjustment of the intermediate frequency will become more and more chaotic. In this case, the fault of non-oscillation should be found and eliminated before adjusting the intermediate frequency.

After the above inspection, if it is determined that the frequency conversion level is working, you can turn up the volume potentiometer, use the magnetic antenna to sense the directional characteristics of the radio signal, and rotate the magnetic antenna. Make the input external signal as small as possible, and then move the position of the antenna coil on the magnetic rod to make the sound as loud as possible. Then use a homemade non-inductive screwdriver to slowly rotate the magnetic cap on the middle cycle in a clockwise direction to make the sound the loudest. The adjustment order is from back to front, that is, from B4 to B2, but when the sound is very loud, it is often difficult for the human ear to distinguish the changes in the sound, and it is not easy to adjust more accurately. Therefore, after the first adjustment, the intensity of the external signal should be weakened and adjusted again; you can also use the volume potentiometer to reduce the volume, and then use the above method to adjust from back to front two or three times.

After the adjustment of the middle cycle is completed, the magnetic cap and core screws of each middle cycle are sealed with wax.

The purpose is to adjust the resonant frequency of the two intermediate frequencies to a fixed intermediate frequency of 465kHz. When adjusting the intermediate frequency, use a non-inductive screwdriver (a small flat-blade screwdriver made of bamboo strips, waste toothbrush handles, hard plastic sheets or bakelite sheets) to adjust the intermediate frequency core. It is not advisable to use a metal screwdriver, because metal screwdrivers are prone to human body induction and inaccurate adjustment.

The adjustment method is: turn on the radio and listen to a radio station at random, then use a wire or a screwdriver to short-circuit the double-connected oscillation stator (that is, use a wire, one end is grounded, and the other end touches the oscillation stator). If the sound disappears immediately or weakens significantly, it means that the frequency conversion stage and the local oscillation circuit are both working. If there is no effect on the sound, it means that the local oscillation is not working, and the signal is passed through the intermediate amplifier stage. At this time, the adjustment of the intermediate frequency will become more and more chaotic. In this case, the fault of non-oscillation should be found and eliminated before adjusting the intermediate frequency.

After the above inspection, if it is determined that the frequency conversion level is working, you can turn up the volume potentiometer, use the magnetic antenna to sense the directional characteristics of the radio signal, and rotate the magnetic antenna. Make the input external signal as small as possible, and then move the position of the antenna coil on the magnetic rod to make the sound as loud as possible. Then use a homemade non-inductive screwdriver to slowly rotate the magnetic cap on the middle cycle in a clockwise direction to make the sound the loudest. The adjustment order is from back to front, that is, from B4 to B2, but when the sound is very loud, it is often difficult for the human ear to distinguish the changes in the sound, and it is not easy to adjust more accurately. Therefore, after the first adjustment, the intensity of the external signal should be weakened and adjusted again; you can also use the volume potentiometer to reduce the volume, and then use the above method to adjust from back to front two or three times.

After the adjustment of the middle cycle is completed, the magnetic cap and core screws of each middle cycle are sealed with wax.

3. Adjust the frequency range (to the scale)

to include the entire band (535-1605kHz) from the lowest frequency when the double link is fully rotated in to the highest frequency when it is fully rotated out. This goal is achieved by adjusting the magnetic core of the oscillation coil of the machine and the compensation capacitor Cb0 of the oscillation circuit.

When the double link is fully rotated in, the dial pointer points to 53 (i.e. 530kHz), and when the double link is fully rotated out, the pointer points to 160 (i.e. 1600kHz). Then, listen to a low-end radio station. For example, China National Radio 640kHz. Rotate the double link so that the pointer points to 640 (i.e. 640kHz). If you cannot receive at this position, you can rotate the double connection again. If you can receive at a position where the pointer is less than 640, it means that the inductance of the oscillation coil is insufficient. You can rotate the magnetic cap of the oscillation coil a little bit until you can receive at 640kHz; if you can receive at a position where the pointer is greater than 640kHz, it means that the inductance of the oscillation coil is large. You can rotate the magnetic cap of the oscillation coil a little bit until you can receive at 640kHz.

Next, choose a high-end radio station to listen to. If the position is a little off, you can adjust the fine-tuning capacitor Cb0 to receive this radio station. It is worth noting that if the fine-tuning capacitor C∞ changes, the low end will be out of tune again, so you need to go back to the low end to adjust. In this way, adjust the magnetic cap of the oscillation coil at the low end, adjust the compensation capacitor at the high end... It takes several times to adjust it.

The simplest method is to use the tuned radio to find the high and low-end radio stations for adjustment.

4. The purpose of unified adjustment (i.e. adjusting the sensitivity of the whole machine)

is to make the local oscillation frequency always higher than the received signal by a fixed frequency of 465kHz. That is to say, their difference frequency is a fixed intermediate frequency of 465kHz, and the intermediate frequency can pass smoothly through the intermediate frequency amplifier.

Therefore, adjusting the local oscillator frequency is the main factor in improving the station selection ability. However, it is difficult to achieve that the local oscillator frequency is higher than the received signal by a fixed intermediate frequency of 465kHz everywhere. At present, the local oscillator frequency can only be higher than the received signal by an intermediate frequency of 465kHz at the high end, middle and low end of the frequency band. This is what is usually called "three-point unified adjustment" or "three-point synchronization".

The specific method is: use the low-end radio station received when adjusting the frequency range to move the position of the magnetic antenna coil on the magnetic rod to maximize the volume, so that the low end is initially adjusted. Then. Use the high-end radio station received when adjusting the frequency range to adjust the fine-tuning capacitor Ca0 in the input circuit to make the sound the loudest, so that the high end is also initially adjusted.

But it should be noted that, like the frequency modulation range, the high and low ends must be adjusted repeatedly several times.

When the high and low ends are initially adjusted, the mid-range can be fine-tuned. For this purpose, you can listen to a radio station near 1000kHz. The sound of the fine-tuning capacitor Ca0 is relatively loud. There are three situations at this time: First, when the capacitor Ca0 is in its original position, the sound is the loudest, which means that the high, medium and low points have been tuned; second, the sound can only be maximized by increasing the capacitance of Ca0, which means that the capacitor Cb1 in the oscillation circuit should be increased (see the figure below) and re-tuned; third, the sound can only be maximized by reducing the capacitance of Ca0, which means that the capacitor Cb1 should be reduced and re-tuned. In short, the sound of Ca0 at the high, medium and low points at the fixed position is the loudest, which is the purpose of the three-point tuning. After tuning, fix the antenna coil with wax.

Finally, it should be explained that the capacitor Cb1 is not set in this radio, and only the high and low ends can be adjusted.

5. Assembly of the radio

When all the radio installation and debugging work is completed, it can be installed. The method is to remove the speaker and power cord, and place the printed circuit board component face down close to the upper cover of the box. Put the speaker into the slot, connect the battery clip, and you are done.

When all the radio installation and debugging work is completed, it can be installed. The method is to remove the speaker and power cord, and place the printed circuit board component face down close to the upper cover of the box. Put the speaker into the slot, connect the battery clip, and you are done.

Latest Communication Circuits Circuits

- Wireless transmission of integrated TV signals for amateur productions

- A cheap and easy-to-make infrared TV signal repeater

- S9018 single tube super regenerative FM receiving circuit

- Convenient and practical telephone automatic redial controller

- MCl3175/MCl3176 FM/AM 928~902 MHz/470~260 MHz Transmitter

- DKl000R OOK 315 MHz Receiver Module

- Cordless phone transmitter circuit

- RF2926 AM/FMASK/FSK/OOK 915/ 868/433 MHz Dual Conversion Transceiver

- rfPICl2C509AG/509AF ASK/FSK 480~310 MHz with 8-bit microcontroller transmitter

- CYWUSB6932 GFSK 2.4 GHz Wireless USB Interface Transmitter

Popular Circuits

- FM-AM two-band radio circuit composed of ULN2204

- USB communication circuit

- Integrated AM and FM radio circuits for household appliances

- Car AM radio circuit diagram

- High quality AM/FM radio circuits

- AM/FM radio circuit using three integrated circuits

- Two-way communication circuit circuit diagram

- Walkman radio circuit diagram

- Clever use of LM386 as a multi-purpose radio circuit diagram

- Clever use of KD-28 as a single-chip radio circuit diagram

京公网安备 11010802033920号

京公网安备 11010802033920号