Introduction

Radio technology has been used for communication for nearly a hundred years. From the original radio broadcasting and wireless telegraph, it has developed into satellite and microwave communication, as well as mobile communication, wireless network, GPS, etc. that are popularized to almost every individual in the world. Wireless communication has greatly changed people's production and lifestyle. Without wireless communication, the goal of information society is unthinkable.

However, wireless communication transmits weak information, not high-power/energy. Therefore, many portable mobile products that are extremely convenient to use have to be connected to the power grid for charging from time to time, and therefore have to leave various sockets and connecting cables. This makes it difficult to achieve a sealing process with waterproof performance, and this personalized cable makes it difficult for chargers of different products to be universal. If these tails are completely removed, mobile terminal devices can gain real freedom. It is also easy to achieve sealing and waterproofing. This goal must require that energy can be transmitted wirelessly like information.

The transmission of energy and the transmission of signals are obviously different. The latter requires the integrity and authenticity of its content, and does not require efficiency, while the former requires power and efficiency. Although the idea of wireless transmission of energy has long been around, it has not been able to enter the practical field because it has not been able to break through the bottleneck of efficiency.

At present, there is still no substantial breakthrough in this bottleneck. However, if there is no strict requirement for the transmission distance (not compared with wireless communication), for example, within a few centimeters (referred to as macro distance in this article), its transmission efficiency can be easily improved to a satisfactory level. If relatively simple equipment can be used to achieve wireless energy transmission under macro distance conditions and form commercial promotion and application, mobile electronic devices that can be seen everywhere in today's society may face a new change.

Working principle

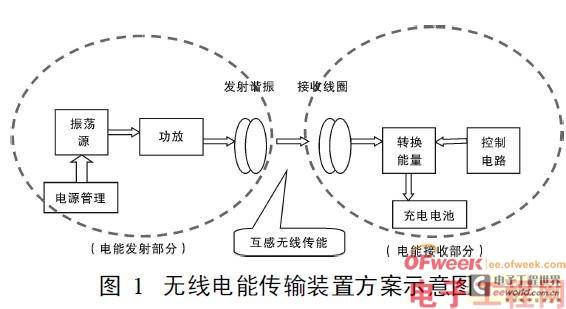

Convert direct current into high-frequency alternating current, and then realize wireless feeding of electric energy through mutual inductance coupling between the primary and secondary coils without any wired connection. The basic scheme is shown in Figure 1.

1 Power transmission part

1 Power transmission part

As shown in Figure 2, there are two power supplies for the wireless power transmission unit: 220V AC and 24V DC (such as car power), which are selected by relay J. According to the principle of AC priority, the normally closed contact of relay J in the figure is connected to DC (battery BT1). Under normal circumstances, S3 is in the on state.

Wireless charging module

When there is AC power supply, the rectified and filtered 26V DC makes relay J close, and the transmission circuit unit works in AC power supply mode. At this time, the DC power supply BT1 is disconnected from the power transmission circuit, and LED1 (green) lights up to show this state.

The +24V DC selected by relay J is mainly used to power the transmitting coil L1. In addition, it is used to power the integrated circuit IC2 after being stepped down by IC1 (78L12). To ensure that the action of J does not affect the stable operation of the transmission circuit, the capacity of capacitor C3 must not be less than 2200uF.

IC1 is a CMOS six-inverter CD4069. Only three inverters are used here. F1 and F2 form a square wave oscillator to generate a square wave of about 1.6MHz. After buffering and shaping by F3, a square wave with an amplitude of about 11V is obtained to excite the VMOS power amplifier tube IRF640. It is enough to make it work in the switching state (class D) to ensure the highest possible conversion efficiency. To ensure that it is consistent with the resonant frequency of the L1C8 loop. C4 can be set to 100pF, and R1 is to be adjusted. For this reason, R1 is temporarily set to 3K and connected in series with the adjustable resistor RP1. In the resonant state, although the excitation is a square wave, the voltage in L1 is a sine wave of the same frequency.

It can be seen that this part is actually a frequency converter, which converts the 50Hz sine into a 1.6MHz sine.

2 Power receiving and charging control part

Under normal circumstances, the receiving coil L2 and the transmitting coil L1 are only a few centimeters apart and are close to coaxial, so a higher transmission efficiency can be obtained.

The principle of the power receiving and charging control circuit unit is shown in Figure 3.

The effective value of the 1.6MHz sine voltage induced by L2 is about 16V (no load). After bridge rectification (composed of 4 1N4148 high-frequency switching diodes) and C5 filtering, a DC of about 20V is obtained. As the only power supply for the charging control part.

The precise reference voltage 4.15V (charging termination voltage of lithium-ion batteries) composed of R4, RP2 and TL431 is connected to the in-phase input terminal 3 of the op amp IC through R12. When the inverting input terminal 2 of IC2 is lower than 4.15V (during the charging process), the high potential output by IC3 saturates Q4, thereby obtaining a stable voltage of about 2V across LED2 (the forward conduction of LED has a voltage-stabilizing characteristic), and Q5, R6, and R7 thus form a constant current circuit I0=2-0.7R6+R7. On the other hand, R5 turns off Q3, and LED3 does not light up.

1 Coupling performance

When the receiving unit is unloaded (not connected to the charged battery), keep L1 and L2 coaxial, change the distance between L1 and L2, and measure the voltage DCV across C5 of the receiving unit. Within

5cm, the charging control circuit can ensure accurate and reliable operation, and charging can still be performed at 6cm.

Disconnect SW, the ammeter reading is 10mA, this is the slow charging working mode; connect SW, the ammeter reading is 30mA, this is the fast charging working mode.

When charging makes the voltmeter reading reach 4.15V, LED3 goes out and LED2 lights up, and the ammeter reading is zero, indicating that the battery BT2 has been fully charged and automatically stops charging, and this state is displayed.

During the test, the battery to be charged can be replaced by a 20000uF capacitor to shorten the charging time and facilitate testing.

3 Energy conversion efficiency

Still keep L1 and L2 coaxial and 2cm apart, and the charger works in fast charging, slow charging and stop charging respectively, and measures.

4 Power switching

Disconnect S1, the relay is reset, and the power is supplied by the DC power supply BT1; connect S1, the relay is energized, and the power is supplied by the AC power supply, and BT1 is disconnected at this time.

The two power supply methods have exactly the same test results for the above.

S3 is used for manual switching of the two power supply methods or forced use of DC, and is generally in the on state.

Conclusion

As a prototype for feasibility exploration experiments, this design is only for small-capacity lithium-ion batteries and lithium polymer batteries of about 100mAh, suitable for pocket digital products such as MP3, MP4 and Bluetooth headsets. There is no principled obstacle to extending it to large-capacity batteries. Of course, from laboratory prototypes to products on the market, there may be relatively long and difficult work, such as electromagnetic radiation leakage problems, cost control and product technology, as well as market entry and consumer startup.

Reference address:Design of wireless charger (schematic diagram + main material bom)

Radio technology has been used for communication for nearly a hundred years. From the original radio broadcasting and wireless telegraph, it has developed into satellite and microwave communication, as well as mobile communication, wireless network, GPS, etc. that are popularized to almost every individual in the world. Wireless communication has greatly changed people's production and lifestyle. Without wireless communication, the goal of information society is unthinkable.

However, wireless communication transmits weak information, not high-power/energy. Therefore, many portable mobile products that are extremely convenient to use have to be connected to the power grid for charging from time to time, and therefore have to leave various sockets and connecting cables. This makes it difficult to achieve a sealing process with waterproof performance, and this personalized cable makes it difficult for chargers of different products to be universal. If these tails are completely removed, mobile terminal devices can gain real freedom. It is also easy to achieve sealing and waterproofing. This goal must require that energy can be transmitted wirelessly like information.

The transmission of energy and the transmission of signals are obviously different. The latter requires the integrity and authenticity of its content, and does not require efficiency, while the former requires power and efficiency. Although the idea of wireless transmission of energy has long been around, it has not been able to enter the practical field because it has not been able to break through the bottleneck of efficiency.

At present, there is still no substantial breakthrough in this bottleneck. However, if there is no strict requirement for the transmission distance (not compared with wireless communication), for example, within a few centimeters (referred to as macro distance in this article), its transmission efficiency can be easily improved to a satisfactory level. If relatively simple equipment can be used to achieve wireless energy transmission under macro distance conditions and form commercial promotion and application, mobile electronic devices that can be seen everywhere in today's society may face a new change.

Working principle

Convert direct current into high-frequency alternating current, and then realize wireless feeding of electric energy through mutual inductance coupling between the primary and secondary coils without any wired connection. The basic scheme is shown in Figure 1.

1 Power transmission part

1 Power transmission part

As shown in Figure 2, there are two power supplies for the wireless power transmission unit: 220V AC and 24V DC (such as car power), which are selected by relay J. According to the principle of AC priority, the normally closed contact of relay J in the figure is connected to DC (battery BT1). Under normal circumstances, S3 is in the on state.

Wireless charging module

When there is AC power supply, the rectified and filtered 26V DC makes relay J close, and the transmission circuit unit works in AC power supply mode. At this time, the DC power supply BT1 is disconnected from the power transmission circuit, and LED1 (green) lights up to show this state.

The +24V DC selected by relay J is mainly used to power the transmitting coil L1. In addition, it is used to power the integrated circuit IC2 after being stepped down by IC1 (78L12). To ensure that the action of J does not affect the stable operation of the transmission circuit, the capacity of capacitor C3 must not be less than 2200uF.

Figure 2 Circuit diagram of wireless power transmission unit

The wireless transmission of electric energy is actually achieved through the mutual inductance of the transmitting coil L1 and the receiving coil L2. Here, L1 and L2 form the primary and secondary coils of a coreless transformer. In order to ensure sufficient power and the highest possible efficiency, a higher modulation frequency should be selected. At the same time, the high-frequency characteristics of the device should be taken into consideration. After experiments, 1.6MHz is more suitable.IC1 is a CMOS six-inverter CD4069. Only three inverters are used here. F1 and F2 form a square wave oscillator to generate a square wave of about 1.6MHz. After buffering and shaping by F3, a square wave with an amplitude of about 11V is obtained to excite the VMOS power amplifier tube IRF640. It is enough to make it work in the switching state (class D) to ensure the highest possible conversion efficiency. To ensure that it is consistent with the resonant frequency of the L1C8 loop. C4 can be set to 100pF, and R1 is to be adjusted. For this reason, R1 is temporarily set to 3K and connected in series with the adjustable resistor RP1. In the resonant state, although the excitation is a square wave, the voltage in L1 is a sine wave of the same frequency.

It can be seen that this part is actually a frequency converter, which converts the 50Hz sine into a 1.6MHz sine.

2 Power receiving and charging control part

Under normal circumstances, the receiving coil L2 and the transmitting coil L1 are only a few centimeters apart and are close to coaxial, so a higher transmission efficiency can be obtained.

The principle of the power receiving and charging control circuit unit is shown in Figure 3.

The effective value of the 1.6MHz sine voltage induced by L2 is about 16V (no load). After bridge rectification (composed of 4 1N4148 high-frequency switching diodes) and C5 filtering, a DC of about 20V is obtained. As the only power supply for the charging control part.

The precise reference voltage 4.15V (charging termination voltage of lithium-ion batteries) composed of R4, RP2 and TL431 is connected to the in-phase input terminal 3 of the op amp IC through R12. When the inverting input terminal 2 of IC2 is lower than 4.15V (during the charging process), the high potential output by IC3 saturates Q4, thereby obtaining a stable voltage of about 2V across LED2 (the forward conduction of LED has a voltage-stabilizing characteristic), and Q5, R6, and R7 thus form a constant current circuit I0=2-0.7R6+R7. On the other hand, R5 turns off Q3, and LED3 does not light up.

Visitor, if you want to view the hidden content of this post, please

reply

Performance Testing

Make sure there is no other metal or magnetic medium near L1 and L2.

1 Coupling performance

When the receiving unit is unloaded (not connected to the charged battery), keep L1 and L2 coaxial, change the distance between L1 and L2, and measure the voltage DCV across C5 of the receiving unit. Within

5cm, the charging control circuit can ensure accurate and reliable operation, and charging can still be performed at 6cm.

2 Charging Control

Keep L1 and L2 coaxial and fixed at a distance of 2cm, connect the battery to be charged, and connect the voltmeter.Disconnect SW, the ammeter reading is 10mA, this is the slow charging working mode; connect SW, the ammeter reading is 30mA, this is the fast charging working mode.

When charging makes the voltmeter reading reach 4.15V, LED3 goes out and LED2 lights up, and the ammeter reading is zero, indicating that the battery BT2 has been fully charged and automatically stops charging, and this state is displayed.

During the test, the battery to be charged can be replaced by a 20000uF capacitor to shorten the charging time and facilitate testing.

3 Energy conversion efficiency

Still keep L1 and L2 coaxial and 2cm apart, and the charger works in fast charging, slow charging and stop charging respectively, and measures.

4 Power switching

Disconnect S1, the relay is reset, and the power is supplied by the DC power supply BT1; connect S1, the relay is energized, and the power is supplied by the AC power supply, and BT1 is disconnected at this time.

The two power supply methods have exactly the same test results for the above.

S3 is used for manual switching of the two power supply methods or forced use of DC, and is generally in the on state.

Conclusion

As a prototype for feasibility exploration experiments, this design is only for small-capacity lithium-ion batteries and lithium polymer batteries of about 100mAh, suitable for pocket digital products such as MP3, MP4 and Bluetooth headsets. There is no principled obstacle to extending it to large-capacity batteries. Of course, from laboratory prototypes to products on the market, there may be relatively long and difficult work, such as electromagnetic radiation leakage problems, cost control and product technology, as well as market entry and consumer startup.

Previous article:High Frequency, High Input Voltage DC/DC Converter Design Challenges

Next article:Solution to Insufficient IC Driving Current in Power Supply Design

- Popular Resources

- Popular amplifiers

-

iPad Mini drawing + bitmap LB 820-3243 schematic diagram and PCB layout.pdf

iPad Mini drawing + bitmap LB 820-3243 schematic diagram and PCB layout.pdf -

USB Complete The Developer\'s Guide 5ed (USB Development Complete 5th Edition)

USB Complete The Developer\'s Guide 5ed (USB Development Complete 5th Edition) -

Automatic detection of bad blocks in MCU Flash memory

Automatic detection of bad blocks in MCU Flash memory -

A section includes USB, thetouchscreen liquid crystal and so on rich peripheral device monolithicint

A section includes USB, thetouchscreen liquid crystal and so on rich peripheral device monolithicint

Recommended Content

Latest Mobile phone portable Articles

- Apple faces class action lawsuit from 40 million UK iCloud users, faces $27.6 billion in claims

- Apple and Samsung reportedly failed to develop ultra-thin high-density batteries, iPhone 17 Air and Galaxy S25 Slim phones became thicker

- Micron will appear at the 2024 CIIE, continue to deepen its presence in the Chinese market and lead sustainable development

- Qorvo: Innovative technologies lead the next generation of mobile industry

- BOE exclusively supplies Nubia and Red Magic flagship new products with a new generation of under-screen display technology, leading the industry into the era of true full-screen

- OPPO and Hong Kong Polytechnic University renew cooperation to upgrade innovation research center and expand new boundaries of AI imaging

- Gurman: Vision Pro will upgrade the chip, Apple is also considering launching glasses connected to the iPhone

- OnePlus 13 officially released: the first flagship of the new decade is "Super Pro in every aspect"

- Goodix Technology helps iQOO 13 create a new flagship experience for e-sports performance

MoreSelected Circuit Diagrams

MorePopular Articles

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

MoreDaily News

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

Guess you like

- Switching Power Supply PCB Layout Technology

- [NXP Rapid IoT Review] + Unfortunately, connection failed

- How to disable ADC to reduce power consumption in ESP32

- After using MAX735 to convert +5V to -5V, the dual-power op amp is powered and -5V is pulled down to 0V

- E104-BT02 Bluetooth wireless transmission module IoT chip intelligent control, collection

- TI CC3200 WIFI Training Development Kit (OURS-SDK-WFB Debug 2 - Familiarity with IAR for ARM.

- Wi-Fi Solutions for IoT Wireless Designs

- Practical Applications of IoT

- MP28GA five-wire four-phase stepper motor debugging

- Adjustment of lv space usage in linux system lvm

iPad Mini drawing + bitmap LB 820-3243 schematic diagram and PCB layout.pdf

iPad Mini drawing + bitmap LB 820-3243 schematic diagram and PCB layout.pdf Automatic detection of bad blocks in MCU Flash memory

Automatic detection of bad blocks in MCU Flash memory

京公网安备 11010802033920号

京公网安备 11010802033920号