Mitsubishi PLC FX3U series is a very popular small PLC with high performance, high reliability, ease of use, etc. In practical applications, remote I/O settings are one of the common requirements.

-

Basic Concepts of Remote I/O

Remote I/O (Remote Input/Output) refers to separating the input/output devices from the PLC and realizing remote control and data exchange through a communication network. Remote I/O can improve the flexibility and scalability of the system, reduce wiring costs, and improve the reliability and safety of the system.

In the Mitsubishi PLC FX3U series, remote I/O can be implemented in a variety of ways, such as using special function modules, expansion modules, remote I/O modules, etc. These modules can be connected to the PLC through communication interfaces such as RS-232, RS-485, and Ethernet.

-

Hardware Hookup

Before setting up remote I/O, you need to understand the PLC hardware connection method. The following are some common hardware connection methods:

2.1 Use special function modules

Special function modules are modules designed for specific applications, such as analog input/output modules, communication modules, etc. These modules can be directly installed on the PLC substrate and communicate with the CPU module through the PLC's internal bus.

2.2 Using extension modules

The expansion module can expand the number of input/output points of the PLC and improve the scalability of the system. The expansion module is connected to the CPU module through the expansion interface of the PLC to realize remote I/O settings.

2.3 Using Remote I/O Modules

Remote I/O modules are independent input/output devices that can be connected to PLC through communication interfaces. These modules can be installed far away from PLC to achieve remote control and data exchange.

-

Software Setup

After the hardware connection is completed, software settings are required to realize the remote I/O function. The following are some common software setting methods:

3.1 Configuring Communication Parameters

When setting up remote I/O, you need to configure communication parameters such as baud rate, data bits, stop bits, parity, etc. These parameters need to be consistent with the parameters of the remote I/O module to ensure the reliability of communication.

3.2 Setting the network address

Remote I/O modules usually have unique network addresses to identify different modules. In the software, these addresses need to be set to achieve control of remote I/O modules.

3.3 Configuring input/output mapping

In the software, the input/output points of the remote I/O module need to be mapped to the input/output address space of the PLC. In this way, the remote I/O module can be controlled by the PLC program.

-

Programming Methods

After completing the hardware connection and software settings, you can start programming to realize the remote I/O function. The following are some common programming methods:

4.1 Using special function instructions

Mitsubishi PLC FX3U series provides some special function instructions, such as DMOV, DCMP, etc., for realizing remote I/O control. These instructions can directly operate the data of remote I/O modules to realize input/output control.

4.2 Using communication commands

Mitsubishi PLC FX3U series supports multiple communication protocols, such as RS-232, RS-485, Ethernet, etc. By using communication instructions, data exchange with remote I/O modules can be achieved.

4.3 Using the PLCopen Motion Control Library

Mitsubishi PLC FX3U series supports PLCopen motion control library, which can easily realize the control of remote I/O modules. These libraries provide rich motion control functions, such as point control, speed control, acceleration control, etc.

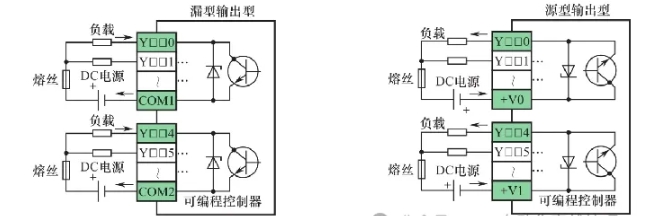

5. Introduction to the output terminal wiring diagram of Mitsubishi plcfx3u:

-

The output types of Mitsubishi FX3U series PLC include relay output and transistor output.

-

When wiring the relay output, pay attention to the voltage range. For DC, use a power supply below DC30V, and for AC, use a power supply below AC240V.

-

The output of the PLC with transistor output is connected to a power supply of DC5V~Dc30V. Transistor output can be divided into two types: source output and sink output. The common end of the source output is positive, represented by +V; the common end of the sink output is negative, represented by Com.

-

Mitsubishi PLC FX3U series remote I/O settings have broad application prospects and can improve the flexibility, scalability and reliability of the system. Through reasonable hardware connection, software settings and programming methods, various complex remote I/O control functions can be realized.

Previous article:Mitsubishi PLCfx3U master control instructions

Next article:Mitsubishi PLC programming instructions

- Popular Resources

- Popular amplifiers

- "Cross-chip" quantum entanglement helps build more powerful quantum computing capabilities

- Why is the vehicle operating system (Vehicle OS) becoming more and more important?

- Car Sensors - A detailed explanation of LiDAR

- Simple differences between automotive (ultrasonic, millimeter wave, laser) radars

- Comprehensive knowledge about automobile circuits

- Introduction of domestic automotive-grade bipolar latch Hall chip CHA44X

- Infineon Technologies and Magneti Marelli to Drive Regional Control Unit Innovation with AURIX™ TC4x MCU Family

- Power of E-band millimeter-wave radar

- Hardware design of power supply system for automobile controller

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Intel promotes AI with multi-dimensional efforts in technology, application, and ecology

- ChinaJoy Qualcomm Snapdragon Theme Pavilion takes you to experience the new changes in digital entertainment in the 5G era

- Infineon's latest generation IGBT technology platform enables precise control of speed and position

- Two test methods for LED lighting life

- Don't Let Lightning Induced Surges Scare You

- Application of brushless motor controller ML4425/4426

- Easy identification of LED power supply quality

- World's first integrated photovoltaic solar system completed in Israel

- Sliding window mean filter for avr microcontroller AD conversion

- What does call mean in the detailed explanation of ABB robot programming instructions?

- STMicroelectronics discloses its 2027-2028 financial model and path to achieve its 2030 goals

- 2024 China Automotive Charging and Battery Swapping Ecosystem Conference held in Taiyuan

- State-owned enterprises team up to invest in solid-state battery giant

- The evolution of electronic and electrical architecture is accelerating

- The first! National Automotive Chip Quality Inspection Center established

- BYD releases self-developed automotive chip using 4nm process, with a running score of up to 1.15 million

- GEODNET launches GEO-PULSE, a car GPS navigation device

- Should Chinese car companies develop their own high-computing chips?

- Infineon and Siemens combine embedded automotive software platform with microcontrollers to provide the necessary functions for next-generation SDVs

- Continental launches invisible biometric sensor display to monitor passengers' vital signs

- BOOST Circuit

- 【Portable Environmental Status Detector】Work Submission

- Are there any electromagnetic radiation issues with LED luminous characters?

- [Share] Solving the problem of operational amplifier instability caused by capacitive load

- Development Background and Characteristics of 5G Industrial Gateway in the Internet of Things

- Smart antenna technology can effectively improve the transmission quality of wireless channels

- MSP430 FRAM Technology – How-tos and Best Practices

- ESP32-CAM Video Surveillance Robot

- Ask the Experts | Confused about DC-DC selection? MPS can help you solve it!

- A comprehensive analysis of dipole antennas

MAX4474EKA+

MAX4474EKA+

京公网安备 11010802033920号

京公网安备 11010802033920号