one

Flying welding

Laser flying welding combines the advantages of remote welding, galvanometer and manipulator, and cooperates with professional graphics processing software to achieve instantaneous multi-track welding in three-dimensional space. It is mainly used in: automobile bodies, seats and common automobile accessories and other products. In terms of materials, it can be applied to various common materials such as steel plates, cold-rolled plates, aluminum alloys, and can also be applied to composite materials and alloy materials such as magnesium-aluminum alloys.

★Advantages ● Any weld form ● Any weld direction ● User-defined weld/point distribution ● Optimized force distribution ● High-speed spot welding, seam welding, stack welding, butt welding, fillet welding and lap welding ● Real-time synchronization between welding head and robot to accelerate the laser welding process ● Less floor space ● Less maintenance and logistics costs

two

Spiral welding

A double wedge laser oscillation laser welding method is realized by configuring a special wobble oscillation module on the welding head. The focused spot produces a spiral weld when the welding head moves. It is mainly used in: hinge welding, heat exchangers, tubular heat exchangers, thick pipe welding of oil and gas, flange welding and aluminum alloy welding, etc.

Spiral welding trajectory diagram

★Advantages ● Widened weld ● High processing repeatability/process stability ● Better weld formability ● Easier post-processing, smoother welded workpiece surface ● Excellent aluminum alloy welding capability

three

Laser brazing

Laser brazing refers to a method of using a filler metal with a lower melting point than the base metal, heating the brazing material to a temperature higher than the melting point of the brazing material and lower than the melting temperature of the base metal, using the liquid brazing material to wet the base metal, fill the joint gap and diffuse with the base metal to achieve the connection of the welded parts. It is mainly used in the welding of aluminum body frame structures, such as the connection between the top cover and the surround, car doors and other products.

Brazing Principle

● Reduce pure laser welding defects, such as pores, cracks, and excessive product clearance ● Improve weld strength and obtain a more perfect weld ● Brazing is the process of melting the brazing material while the parent material does not melt ● Brazing has small deformation, smooth and beautiful joints, and is suitable for welding precise, complex components made of different materials ● Small heat-affected area and high compressive strength

Four

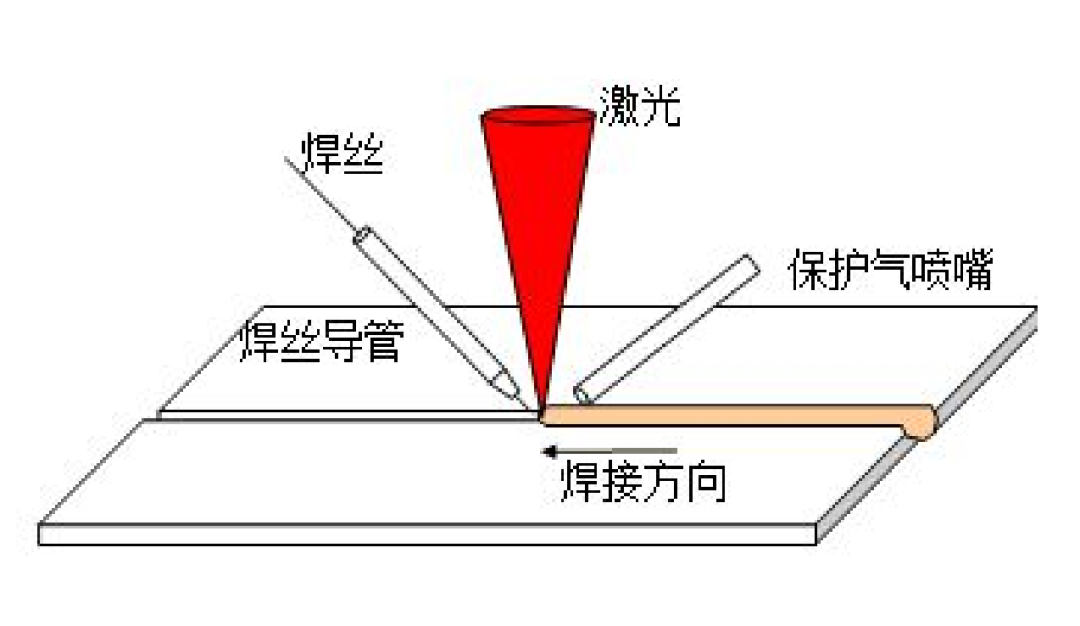

Laser welding with filler wire

Laser wire welding is a method of using filler metal of the same or similar material as the base material to melt the base material and the brazing material and then condense to form a weld. It is mainly used in: vehicle body structural parts and auto parts products.

Welding metallographic diagram

★Advantages ● Reduce pure laser welding defects, such as pores and cracks ● Improve the difference rate of welding products, allowing a slightly larger gap between welding products ● The welding base material is melted, and the welding strength is stronger than the base material

five

Swing brazing

ALO3 integrates beam shaping and weld tracking functions in the same device. Filler wire can be used as a mechanical sensor. It is mainly used in laser welding of body-in-white, including laser brazing of roof cover and trunk lid, and brazing of automotive parts. The fluctuation of parts and the error of fixtures often increase the difficulty of laser brazing, making the laser welding debugging process extremely difficult, but swing brazing can effectively adjust its own welding direction, weld tracking and automatic focal length compensation functions, which can make the laser beam easy to guide and focus, realize the transformation of various directions, with high degree of automation, fast welding speed and high efficiency, so that it can maintain welding quality.

ALO3 ★Advantages ● Weld seam tracking, real-time determination of workpiece weld seam trajectory ● According to the different deviations of different workpieces, the welding trajectory can be adaptively adjusted in three directions, XYZ, to obtain good welding quality ● Improve product welding consistency

six

Three-spot brazing

Add a dual spot module to the lens. During welding, the three spot module in the brazing optics distributes one beam into three beams, providing a solution for brazing hot-dip galvanized steel sheets. Make the weld smoother and crack-free. Mainly used in: aluminum alloy brazing of white body, laser brazing of roof cover and trunk cover, and brazing of automotive parts. ★Advantages ● More stable and reliable brazing process ● Faster speed ● Higher strength ● Higher appearance surface quality of hot-dip galvanized sheet welding ● Online cleaning process ● Dynamic energy adjustment

seven

Multi-wavelength composite welding

Multi-wavelength composite welding is a welding process pioneered by Lianying Laser. It is achieved by superimposing two lasers of different wavelengths so that the axes of the two laser beams overlap in space. The main-band laser is mainly used for welding, while the secondary-band laser is mainly used to preheat the welding wire and the base material and reduce the cooling rate of the molten metal in the welding pool. It is particularly suitable for aluminum alloys, magnesium alloys, copper alloys, etc.

Hybrid welding beam

★Advantages ● Reduce the porosity content ● Increase the stability of the welding bead and increase the welding efficiency value ● Effectively relieve thermal stress to reduce cracks, improve weld strength and obtain a weld with a more uniform appearance

【summary】

At present, the laser industry as a whole is still in the leading position of foreign technology and equipment, from laser host, optical processing head, to chiller, power meter, welding monitoring, post-welding detection, TCP calibrator and other auxiliary equipment, and domestic enterprises are trying their best to catch up. In the field of laser welding application, my country is relatively close to the international advanced level, and a number of high-quality enterprises have emerged and achieved excellent results.

Previous article:Analysis of 48V vehicle low-voltage power supply system from the perspective of functional safety

Next article:Unveiling the secrets of electric vehicle IGBT chip bonding wire

- Popular Resources

- Popular amplifiers

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- What are the functions of the Internet of Vehicles? What are the uses and benefits of the Internet of Vehicles?

- Power Inverter - A critical safety system for electric vehicles

- Analysis of the information security mechanism of AUTOSAR, the automotive embedded software framework

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Problems with devices that measure temperature

- Difference between Ethernet and Broadband

- Interpretation of how dust and water resistance testing of lamps is applied in international standards

- Is it as shown in the picture?

- PCB file conversion

- 5G indoor base stations will be released soon, and it is expected that each household will have a small base station, which will subvert the existing home Internet access methods.

- How to consider the impact of audio analog signals after being transmitted through a 100m long cable?

- Angle sensor

- Transistor Selection

- NUCLEO_G431RB Review - RTC Real-time Clock

FOUNDRY PROCESS QUALIFICATION GUIDELINES – TECHNOLOGY QUALIFICATION VEHICLE TESTING JEP001-3B

FOUNDRY PROCESS QUALIFICATION GUIDELINES – TECHNOLOGY QUALIFICATION VEHICLE TESTING JEP001-3B

京公网安备 11010802033920号

京公网安备 11010802033920号