Customizable on-chip peripherals subvert traditional logic, TI helps engineers unleash their creativity

It’s a familiar scene in labs around the world: Design engineers push the limits, trying to add functionality or improve performance. However, when they drill down to the underlying system timing, they hit a design impasse. Because they may need to change the solution for a critical control signal. This situation limits engineers’ creativity and only hopes: “I wish I could customize the logic and timing within the control peripheral.” Now, with the Configurable Logic Blocks (CLBs) of C2000™ microcontrollers (MCUs), this wish has become a reality.

What is a CLB? CLB integrates an optimized high-speed programmable logic into a real-time controller such as a C2000 MCU, providing intelligent signal input/output (I/O) routing capabilities for key peripherals such as enhanced pulse width modulator (PWM), enhanced capture, enhanced quadrature encoder, and general purpose I/O, ultimately becoming an enhanced intellectual property (IP) block with system-level differentiation.

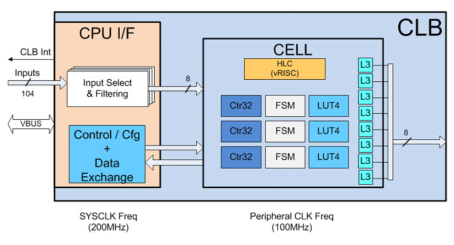

Figure 1: Example of a CLB tool unit block

As shown in Figure 1, the CLB tool consists of two, four, or eight logic blocks, each of which contains a complete set of optimized programmable logic cells, including:

-

Three 4-input look-up tables (LUT4)

-

Three 32-bit counters (Ctr32)

-

Three 4-state finite state machines (FSM)

-

Eight 3-input-output lookup tables (L3)

-

A high level controller (HLC)

By configuring these blocks individually and connecting them together, you can generate custom logic schemes that provide novel solutions to complex system problems, such as writing application-specific logic for protection trigger conditions, enhancing types of soft-switching PWM, or implementing quadrature encoder position capture based on special conditions.

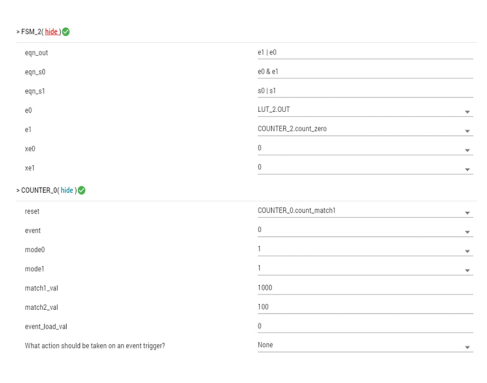

To facilitate development, TI created a graphical CLB configuration tool (shown in Figure 2) and integrated it directly into TI's Code Composer Studio™ integrated development environment for code development and debugging.

Figure 2: CLB tool configuration view

After configuration, the system will automatically generate the CLB tool output logic. The project compilation output is a *.h header file that describes the CLB tool configuration. During runtime initialization, the header file descriptor calls the C2000Ware DriverLib application programming interface function to configure the logic block.

Increasingly, design engineers are using CLB tools to explore new ways to differentiate their products. Matt Parnell, lead hardware engineer for Harman International's Lifestyle Audio division, has been using CLB to enhance his products.

According to Matt, they are always looking to “push the limits of design.”

“For example, we now move the main function’s software control loop to the CLB, offloading the user control logic and diagnostics. This reduces the per-cycle overhead of the 400kHz frequency, which is very effective and necessary. The bandwidth freed up by reducing the per-cycle overhead can be directly used to improve control functions,” said Matt.

He also talked about how the enhanced PWM (ePWM) peripheral integrates the signals “under the hood.”

“Within the CLB, designers can intercept the internal ePWM signals, including the action indicators and signals for deadband and logic conditions, and then create customized versions of the submodules. Harman has already used this capability to achieve new wins. The CLB adds a lot of customization to an already powerful device.”

The new CLB peripheral overcomes the barriers of control class design and provides a new toolset for creating differentiated solutions. The latest C2000Ware release includes 15 CLB examples; encoder examples are available in the MotorControl software development kit. Check out the training and application manuals to see how CLBs can disrupt traditional logic.

Previous article:SuperTest helps eSOL deliver a safety-compliant real-time embedded software platform

Next article:Practical tips for MCU software benchmarking: Guidelines for evaluating compiler optimization capabilities

Recommended ReadingLatest update time:2024-11-16 11:46

- Popular Resources

- Popular amplifiers

-

Wireless Sensor Network Technology and Applications (Edited by Mou Si, Yin Hong, and Su Xing)

Wireless Sensor Network Technology and Applications (Edited by Mou Si, Yin Hong, and Su Xing) -

Modern Electronic Technology Training Course (Edited by Yao Youfeng)

Modern Electronic Technology Training Course (Edited by Yao Youfeng) -

Modern arc welding power supply and its control

Modern arc welding power supply and its control -

Small AC Servo Motor Control Circuit Design (by Masaru Ishijima; translated by Xue Liang and Zhu Jianjun, by Masaru Ishijima, Xue Liang, and Zhu Jianjun)

Small AC Servo Motor Control Circuit Design (by Masaru Ishijima; translated by Xue Liang and Zhu Jianjun, by Masaru Ishijima, Xue Liang, and Zhu Jianjun)

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- What are the functions of the Internet of Vehicles? What are the uses and benefits of the Internet of Vehicles?

- Power Inverter - A critical safety system for electric vehicles

- Analysis of the information security mechanism of AUTOSAR, the automotive embedded software framework

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- CCS compilation error: unresolved symbols remain solution

- Fiber Optic Project Overview

- Bluetooth module problem

- Switching Power Supply Interest Group 13th Task

- Is the ST website down? Or is it crashing?

- How to Design a Low-Cost Bluetooth Music Playback System

- I would like to ask which other manufacturers have single-pole TMR switches, except MDT (only a model, but out of stock)?

- PIC16F684 IO port output problem

- The difference between building a system and building a module

- Complete learning and application of analog electronic technology with examples

Wireless Sensor Network Technology and Applications (Edited by Mou Si, Yin Hong, and Su Xing)

Wireless Sensor Network Technology and Applications (Edited by Mou Si, Yin Hong, and Su Xing)

京公网安备 11010802033920号

京公网安备 11010802033920号