In the past two years, as the popularity of new energy vehicles has continued to rise, consumers' primary consideration when choosing electric vehicles is mileage, and advanced battery management systems (BMS) can help overcome the key obstacles that prevent the widespread popularization of electric vehicles. Wang Shibin, general manager of Texas Instruments' Battery Management System Division, said: " TI has always paid attention to new energy vehicles and continuously provided innovative technologies, hoping to help new energy vehicle manufacturers extend their mileage to a greater extent, which requires higher battery monitoring accuracy." Therefore, TI focuses on overcoming complex system design challenges and provides a rich and advanced BMS device series to help automakers create a safer and more reliable driving experience and increase the popularity of electric vehicles.

On January 12, 2023, TI announced the launch of new automotive cell monitors and battery pack monitors. These monitors provide higher-precision measurement capabilities to maximize electric vehicle (EV) driving time and achieve safer operation.

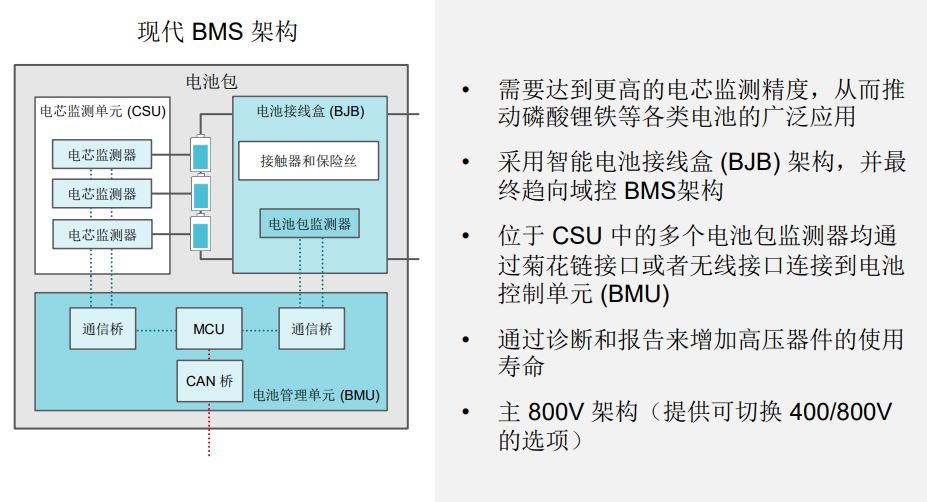

The block diagram on the right is the architecture of what we call a battery junction box in a battery pack . In a traditional battery junction box, there are usually many leads, wiring, and interfaces connected to the BMU (battery management) unit. If you want to measure the high voltage of the battery, including the parameters inside the battery box, through the BMU unit, you will need a lot of wiring harnesses. However, the solution of the smart junction box can integrate the functions of the high-precision current monitoring system, diagnostic system, and communication module of the battery pack into a chip product specifically for the smart battery box, eliminating the complicated wiring harness.

The traditional architecture has many wires between the junction box and the CSU to transmit the information collected by the battery, which makes the number of wires very large. TI's complete solution can support daisy chain communication with only two wires. At the same time, TI supports the transmission of battery monitoring information through wireless communication, which is conducive to further reducing the number of wire harnesses and giving end users more choices.

High-precision Battery Monitor BQ79718-Q1

BQ79718-Q1 is a voltage measurement monitor that can achieve very high accuracy, which can very well estimate the real driving range of electric vehicles. At the same time, because it can achieve very high accuracy, the reliability and safety of battery pack charging and discharging are very high, which can better reduce the evaluation error of the remaining driving range of electric vehicles while meeting ASIL requirements.

The BQ79718-Q1

can

detect

abnormalities with an accuracy of up to 1mV, which means that this product can be applied to batteries of different chemical compositions, including mainstream lithium iron phosphate batteries, which enables electric vehicles to achieve higher accuracy in mileage calculation.

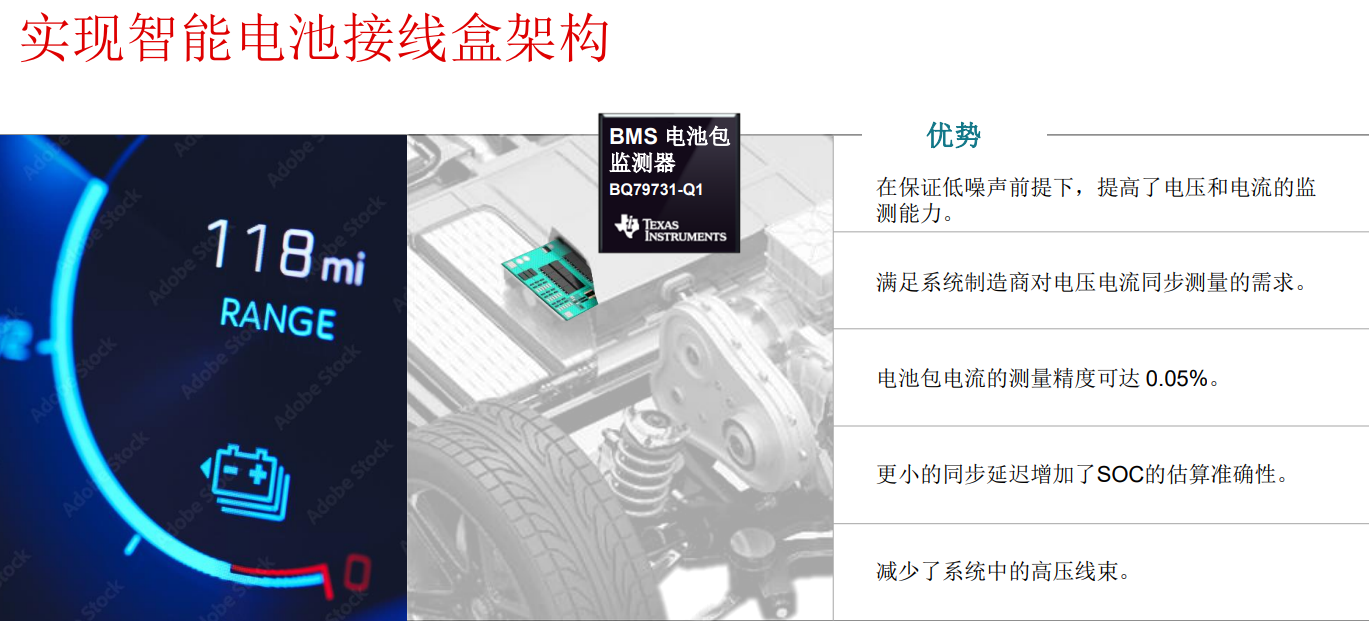

According to Wang Shibin, the BQ79718-Q1 battery cell monitor is mainly used to measure voltage, and the BQ79731-Q1 battery pack monitor in the junction box is mainly used to measure current. There is a very good synchronization function between the voltage and current measurements. The synchronization delay is very small, only 128 microseconds, which allows us to calculate the current parameters of the electric vehicle very accurately. These accurate parameters enable the entire system to better evaluate the mileage that the car can travel in the future.

TI also pays great attention to improving the overall vehicle safety level, that is, the accuracy of ASIL required by vehicle regulations. For the detection of all parameters , there are main detection paths and redundant paths, both of which detect the same parameter at the same time.

Implementing a Smart Junction Box Battery Pack Monitor BQ79731-Q1

In addition to battery cell detection, battery pack detection is also crucial. In response to this technical demand, TI has launched the BQ79731-Q1 battery pack monitor for smart junction boxes, which can monitor the current parameters of smart battery packs with very high precision and meet customers' needs for synchronous measurement of voltage and current. The products in the battery pack can be used in conjunction with some existing battery cell monitor products. They work together to meet the high requirements for synchronous current and voltage measurement to achieve the expected measurement effect. Because smaller synchronization delays can more accurately evaluate the state of charge of the battery pack and achieve more precise evaluation.

TI actively responds to BMS challenges

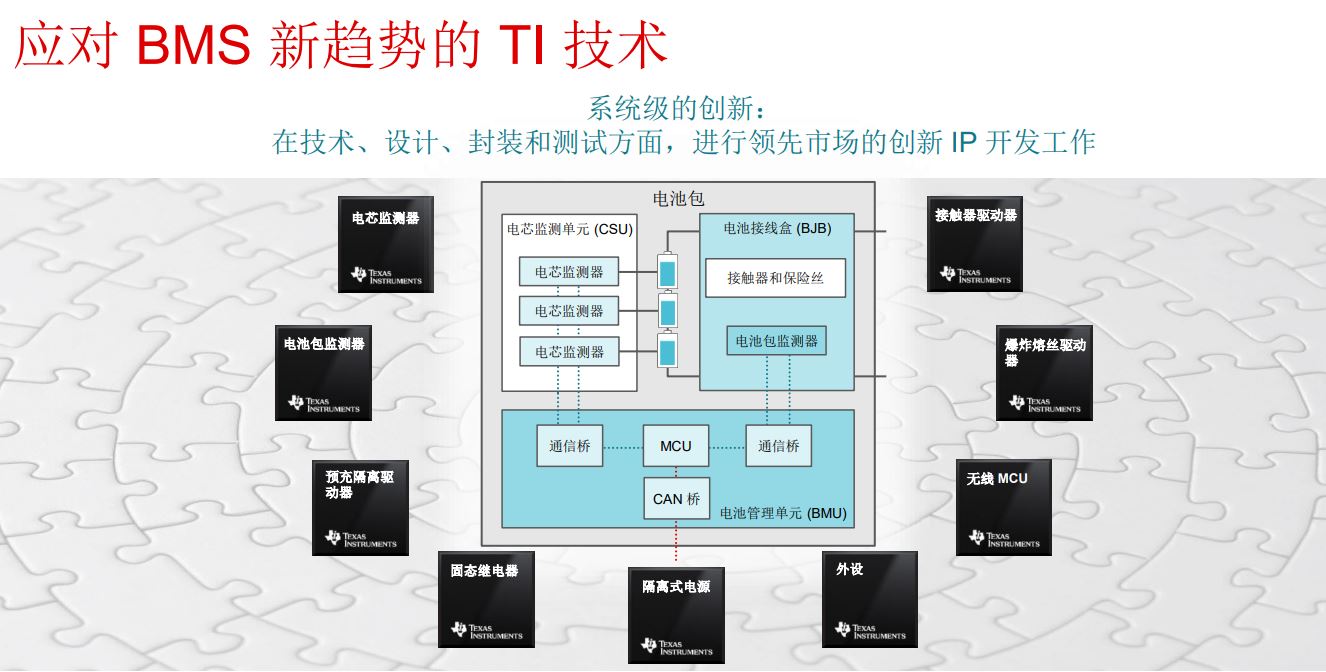

When introducing TI's response to the BMS challenge, Wang Shibin said that TI has rich experience in power management and continues to study how to reduce the size of power management systems and improve performance. In terms of battery management support, TI can achieve compatibility with different battery architectures and battery numbers (such as 12 batteries, 16 batteries, and even up to 18 batteries) by optimizing the topology. This means that when designing a specific system, better sharing of some software and hardware can be achieved, which can also improve design efficiency.

At the same time, TI's products improve battery measurement accuracy, including improving the measurement accuracy of temperature parameters and precise current parameters, and optimizing thermal management to enhance the safety performance of the entire battery system.

At the system level of the entire battery pack, TI has a full range of system solutions to solve customers' problems. In addition to the cell monitoring chip and the battery pack monitoring chip, TI also has very complete other solutions, such as pre-charge drivers, solid-state relays, isolated power supplies, wireless controllers and other related cell battery solutions.

Previous article:Under the new wave of automobiles, how can mainstream joint venture car companies win the future?

Next article:The key to driverless driving: high-precision positioning box P-Box

- Popular Resources

- Popular amplifiers

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Tektronix Industrial Application Standard and High-Speed Interface Test Solutions

- Ora Good Cat “chip replacement incident”: How big is the gap between the two chips?

- 【NUCLEO-L552ZE Review】+ Bluetooth communication experiment (1)

- Sigma-Delta ADC Digital Filter Types

- Remote upgrade of HuaDa MCU HC32L110

- Explanation of the stack pointer register SP of msp430

- Qorvo at CES 2020: Innovative Solutions for 5G, IoT, Wi-Fi 6 and V2X

- dsp28335 Ecap Summary

- Motor drive control essence summary post

- Preliminary analysis of the G problem of the electronic competition

KF442ACN

KF442ACN

京公网安备 11010802033920号

京公网安备 11010802033920号