Harald Kroeger, member of the Bosch Group’s board of management: “Bosch wants to become the world’s leading supplier of silicon carbide (SiC) chips for electric mobility.”

Silicon carbide semiconductors can significantly increase the driving range and charging speed of electric vehicles.

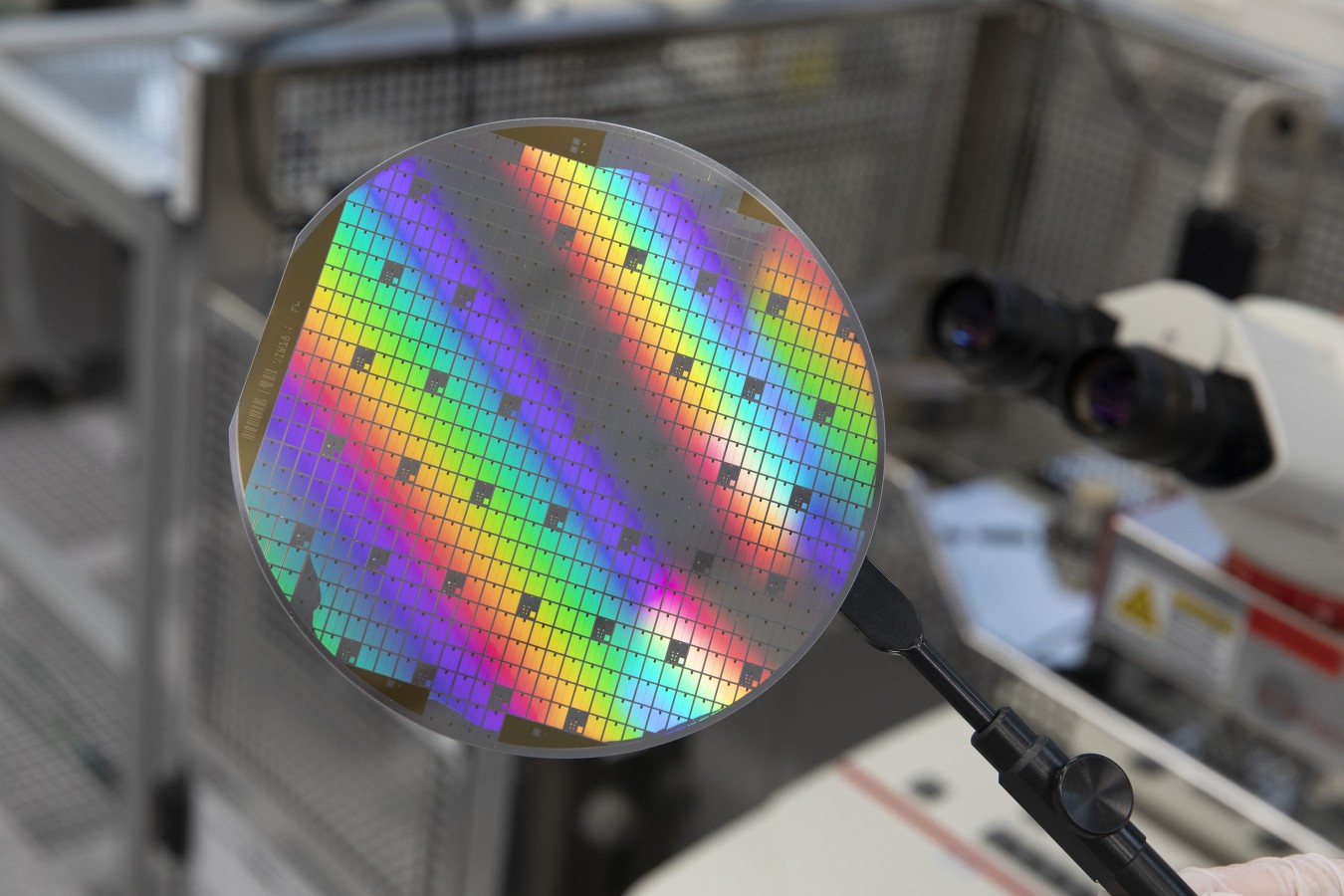

Large-scale production is expected to start in December 2021. Bosch has been producing silicon carbide chips for customer verification since the beginning of 2021.

The German Federal Ministry for Economic Affairs and Energy (BMWi) is funding further technological development.

Silicon carbide (SiC) semiconductors have significant advantages of small size, high efficiency and high power density. After years of research and development, Bosch is now preparing to start mass production of power semiconductors made of this innovative material to provide to major global automakers. In the future, more and more mass-produced cars will be equipped with Bosch's silicon carbide chips. "Silicon carbide semiconductors have broad development prospects, and Bosch hopes to become the world's leading supplier of silicon carbide chips for electric mobility." Harald Kroeger, member of the Bosch Group Board of Management, said. As a world-leading technology and service provider, Bosch announced two years ago that it would continue to promote the development and mass production of silicon carbide chips. To achieve this goal, Bosch has independently developed extremely complex manufacturing processes and began producing samples for customer verification in early 2021. "Thanks to the booming field of electric mobility, Bosch has received quite a lot of orders for silicon carbide semiconductors," said Kroeger. In the future, Bosch will continue to expand the production capacity of silicon carbide power semiconductors, aiming to increase output to hundreds of millions of units. To this end, Bosch has begun to expand the dust-free workshop of the Reutlingen plant, and is also working on the development of second-generation silicon carbide chips with higher power density, which are expected to be put into mass production in 2022. Bosch's R&D innovation in silicon carbide semiconductor manufacturing processes has also been supported by the German Federal Ministry for Economic Affairs and Energy (BMWi) and has become part of the microelectronics field of the "Important Project of Common European Interest (IPCEI)". "For many years, we have been supporting companies to develop the German semiconductor manufacturing industry. Bosch's high level of innovation in semiconductor production has not only strengthened the European microelectronics ecosystem, but also further enhanced the independence of the microelectronics industry in key areas of digital development." said Peter Altmaier, Minister of the German Federal Ministry of Economic Affairs and Energy.

The key to improving mileage

Globally, demand for silicon carbide power semiconductors continues to rise. According to forecasts released by market research consulting firm Yole, the silicon carbide market will grow by 30% annually from now to 2025, and the market size will exceed $2.5 billion. When the size reaches $1.5 billion, cars equipped with silicon carbide devices will dominate the market. "Silicon carbide power semiconductors are extremely efficient, and their advantages are becoming more and more obvious in energy-intensive applications such as electric mobility," said Kroeger. In the field of power electronics for electric vehicles, the configuration of silicon carbide chips can effectively extend the driving distance on a single charge. Compared with electric vehicles using pure silicon chips, electric vehicles equipped with silicon carbide chips have an average driving distance extended by 6%. To meet the growing demand for silicon carbide power semiconductors, Bosch has added 1,000 square meters of clean rooms in the Reutlingen wafer factory in 2021. By the end of 2023, Bosch will also build a new 3,000 square meters of clean rooms. The new clean room will be equipped with state-of-the-art production facilities and use self-developed manufacturing processes to produce silicon carbide semiconductors. To this end, Bosch's semiconductor experts have made full use of Bosch's decades of chip manufacturing expertise. In the future, Bosch, as the only automotive parts supplier that produces silicon carbide chips independently, plans to use 200 mm wafers to manufacture silicon carbide semiconductors. Compared with the 150 mm wafers used today, the use of 200 mm wafers can bring considerable economies of scale. After all, it takes several months for a single wafer to complete hundreds of process steps in countless machines and equipment. "Using large-size wafers for production can manufacture more chips in one production cycle, thereby meeting the needs of more customers." Kroeger said.

Small atoms, big energy

The powerful performance of silicon carbide chips is due to tiny carbon atoms. Adding these carbon atoms to the crystal structure of high-purity silicon used to make semiconductors gives the raw material special physical properties, such as supporting higher switching frequencies. In addition, silicon carbide semiconductors have only half the heat loss of pure silicon chips, which can increase the driving range of electric vehicles. Silicon carbide chips are also crucial for 800-volt voltage systems, which can speed up charging and improve product performance. Since silicon carbide chips emit significantly less heat, they can save power electronics cooling costs, reduce the weight of electric vehicles themselves, and reduce the cost of the entire vehicle. In the future, Bosch will provide silicon carbide power semiconductors to customers around the world, either as a single chip or built into overall solutions such as power electronics or electric bridges. Thanks to a more efficient overall system design, the electric bridge, which combines the motor, inverter and reducer, can achieve a maximum efficiency of 96%, providing more energy redundancy for the powertrain system, thereby further increasing the driving range.

The Bosch Group is a world-leading supplier of technology and services. The Bosch Group has nearly 403,000 employees (as of December 31, 2019). According to preliminary data, sales of 77.9 billion euros were generated in the 2019 fiscal year. Bosch's business is divided into four business areas, covering automotive and intelligent transportation technology, industrial technology, consumer goods, and energy and building technology. As a world-leading IoT company, Bosch provides innovative solutions for smart homes, smart cities, connected transportation, and connected industries. Bosch uses its expertise in sensor technology, software, and services, as well as its own cloud platform, to provide customers with integrated cross-domain connected solutions. Through its products and services, Bosch provides people with innovative and beneficial solutions to improve their quality of life and create a connected life. With its innovative technology, Bosch is fulfilling its promise of "Technology Makes Life Beautiful" worldwide.

The Group includes Robert Bosch GmbH and its 440 branches and regional companies in about 60 countries. If its sales and service partners are included, Bosch's business covers almost every country in the world. Bosch's long-term and healthy development is based on continuous innovation. Bosch's R&D network has 72,000 R&D personnel in 125 countries and regions around the world.

The company was founded in 1886 in Stuttgart by Robert Bosch (1861-1942) as "Workshop for Precision Mechanics and Electrical Engineering". The unique ownership structure of the Bosch Group guarantees its financial independence and autonomy in corporate development, enabling the Group to make long-term strategic plans and forward-looking investments to ensure its future development. The charitable Robert Bosch Foundation owns 92% of the shares of Robert Bosch GmbH, and the majority of voting rights are held by the Robert Bosch Industrial Trust. The trust also exercises corporate ownership functions. The remaining shares belong to the Bosch family and Robert Bosch GmbH.

Previous article:Samsung Semiconductor launches three new automotive chip solutions

Next article:LG Electronics plans to directly develop and produce automotive semiconductor MCUs

Recommended ReadingLatest update time:2024-11-16 14:35

- Popular Resources

- Popular amplifiers

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- TMS320F28335 general purpose input/output port GPIO related register introduction

- On-line debugging method for embedded processors

- "Qinheng Evaluation Board Sincerely Send" Activity Q&A Post

- Has anyone used the Raspberry Pi Cm3+?

- AVR MCU nrf24l01 driver

- Circuit Design Considerations

- PWM output of MSP430 library timer TA

-

[NXP Rapid IoT Review] +

NXP Rapid IoT, a simplest cloud server prototype - EEWORLD University ---- Computer Control Technology

- Please advise, why do you need to remove the motherboard before burning the flash?

Progress in high-power silicon carbide power electronic devices

Progress in high-power silicon carbide power electronic devices

京公网安备 11010802033920号

京公网安备 11010802033920号