On September 15, semiconductor component distributor WPG Holdings announced that its subsidiary Pinjia has launched a CAN/LIN communication matrix headlight solution based on Microchip's PIC16F1779, Onsemi's NCV78343 and OSRAM LED.

Figure 1- A physical picture of the CAN/LIN communication matrix headlight solution launched by WPG in collaboration with several well-known companies

As people's requirements for cars continue to increase, more and more electronic control devices are being used in cars. While these electronic control devices improve car comfort, they also lead to increasingly complex car wiring harnesses. For this reason, GPON has launched a CAN/LIN communication matrix headlight solution based on Microchip, Onsemi and OSRAM products, aiming to use serial communication networks to replace cumbersome on-site wiring to solve the above problems.

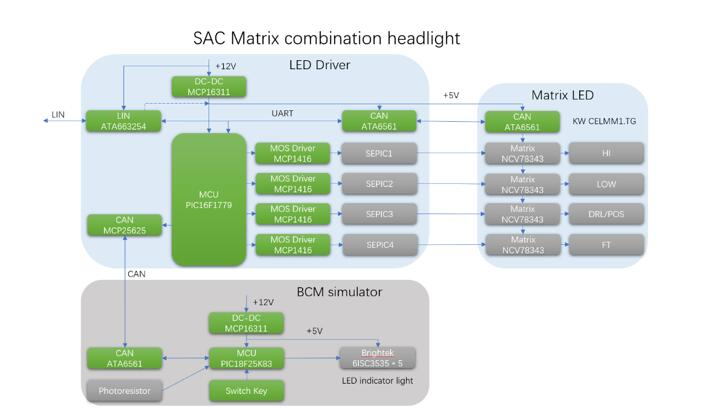

Figure 2- Block diagram of the CAN/LIN communication matrix headlight solution launched by WPG in collaboration with several well-known companies

The core of this solution uses Microchip's PIC16F1779 MCU, which integrates core-independent peripheral modules to implement switching power supply control, logic control and communication functions. Compared with pure analog or ASIC implementation solutions, it can significantly improve flexibility. In addition, the PIC16F1779 can independently control up to four LED channels, which is a unique capability that most LED driver controllers do not have, and is particularly suitable for the design of combined headlights/taillights. In addition, this solution also integrates Onsemi's NCV78343 matrix control chip and OSRAM's excellent LED products, which will further improve the performance of CAN/LIN communication matrix headlights.

Figure 3- Application diagram of CAN/LIN communication matrix headlight solution launched by WPG in collaboration with many well-known companies

As an excellent communication matrix headlight solution, it integrates four LED dimming engines on a single MCU, which can achieve up to four completely independent LED light string constant current drive, and adopts SEPIC buck-boost topology, which has a wider range of applications. For different LED loads, you only need to adjust the output voltage and current in the software.

The LED dimming engine consists of analog peripherals integrated in the microcontroller, which are connected through MCC configuration to form four independent LED dimming drivers. After the configuration is completed, the system can control the switch-mode power converter by itself with almost no intervention from the central processing unit (CPU), which can free up the CPU to perform other important tasks, such as monitoring functions, communication functions or newly added intelligent functions in the system.

Core technology advantages:

PIC16F1779 single hybrid power MCU (built-in PRG slope compensation, OPA op amp, COMP comparator, COG complementary waveform generator, DAC, ADC, USART and other peripherals), can realize four-way SEPIC buck-boost constant current drive, CAN/LIN protocol processing, matrix chip animation control;

· PCMC peak current mode is used to quickly respond to load changes, SEPIC topology is used to achieve buck-boost, single-channel constant current can reach 1A (pay attention to LED heat dissipation), and PWM dimming is supported;

Hardware-level overvoltage protection, automatically shutting down PWM output when overvoltage occurs;

· Detect the terminal voltage of the LED light string to determine LED open circuit, short circuit and other faults, and feedback to the BCM simulator through CAN communication to display on the indicator light;

NTC thermistor detects LED temperature to achieve overheat protection and over-temperature derating operation;

· Use photoresistor to detect ambient light intensity to realize automatic headlight function;

· Simulate BCM to send CAN commands to control headlight on/off, dimming, power on/off animation, matrix control, reset, voltage/status/fault feedback;

· Four-way drive to achieve combined headlight functions, including high beam, low beam, daytime running lights, position lights, and turn signals. (Daytime running lights and position lights share the third group of drivers, and the brightness is adjusted through software);

NCV78343 UART Over CAN communication supports long-distance transmission. Automatic addressing at power-on, 4 cascaded LEDs can realize independent control of 48 (12*4) LEDs;

Modular design facilitates modification and replacement of modules to match different functional requirements;

Support MPLAB X IDE MCC graphical code configuration plug-in, graphically generate low-level drivers, and quickly develop;

The carefully designed SAC_CAN_LED_Lib SDK development package provides functions such as four-way PCMC constant voltage/constant current drive, PWM dimming, MCP25625 CAN drive, USART drive, frequency jitter, etc., and provides API interface;

· After signing the NDA, we can provide schematics, PCB diagrams, bill of materials, software sample source code, SDK development kit, and CAN communication protocol.

Program Specifications:

PWM frequency: 333KHz (250KHz~500KHz software adjustable);

Conversion efficiency: 82%~85%;

Over-temperature protection: above 112.5℃, the rating is reduced to 80%, above 122.5℃, the rating is reduced to 70%. (Software adjustable);

LED fault detection: support;

LIN communication: Support (use MCC to generate code);

CAN communication: Support (driver API is provided in SDK), support control, status and fault feedback;

· Switch control: support;

Digital frequency jitter: support (software adjustable);

Soft start: Support (software adjustable);

· Input reverse connection protection: support;

Current resolution: 6.66666667mA (related to the value of the LED current sampling resistor; the larger the resistance, the higher the resolution);

Maximum power: 40W x 4 channels;

Input voltage: DC 9V~24V;

Matrix control: NCV78343, maximum 1.5A*12 LEDs*4 channels;

Animation effects: startup animation, shutdown animation.

Previous article:Huawei's new HUD, 70-inch screen front glass.

Next article:Huawei's Wang Jun: In-vehicle displays have entered the era of optical imaging and major events have occurred recently

- Popular Resources

- Popular amplifiers

- 2024 China Automotive Charging and Battery Swapping Ecosystem Conference held in Taiyuan

- State-owned enterprises team up to invest in solid-state battery giant

- The evolution of electronic and electrical architecture is accelerating

- The first! National Automotive Chip Quality Inspection Center established

- BYD releases self-developed automotive chip using 4nm process, with a running score of up to 1.15 million

- GEODNET launches GEO-PULSE, a car GPS navigation device

- Should Chinese car companies develop their own high-computing chips?

- Infineon and Siemens combine embedded automotive software platform with microcontrollers to provide the necessary functions for next-generation SDVs

- Continental launches invisible biometric sensor display to monitor passengers' vital signs

- Intel promotes AI with multi-dimensional efforts in technology, application, and ecology

- ChinaJoy Qualcomm Snapdragon Theme Pavilion takes you to experience the new changes in digital entertainment in the 5G era

- Infineon's latest generation IGBT technology platform enables precise control of speed and position

- Two test methods for LED lighting life

- Don't Let Lightning Induced Surges Scare You

- Application of brushless motor controller ML4425/4426

- Easy identification of LED power supply quality

- World's first integrated photovoltaic solar system completed in Israel

- Sliding window mean filter for avr microcontroller AD conversion

- What does call mean in the detailed explanation of ABB robot programming instructions?

- STMicroelectronics discloses its 2027-2028 financial model and path to achieve its 2030 goals

- 2024 China Automotive Charging and Battery Swapping Ecosystem Conference held in Taiyuan

- State-owned enterprises team up to invest in solid-state battery giant

- The evolution of electronic and electrical architecture is accelerating

- The first! National Automotive Chip Quality Inspection Center established

- BYD releases self-developed automotive chip using 4nm process, with a running score of up to 1.15 million

- GEODNET launches GEO-PULSE, a car GPS navigation device

- Should Chinese car companies develop their own high-computing chips?

- Infineon and Siemens combine embedded automotive software platform with microcontrollers to provide the necessary functions for next-generation SDVs

- Continental launches invisible biometric sensor display to monitor passengers' vital signs

- 3 serial ports, multiple serial ports, dual serial ports, and 2 serial ports to WiFi multi-hop communication implementation

- TI AM335x Development Board - CAN Bus User Manual

- Write EEPROM, write FLASH experience record

- Xiaomi, OnePlus, and Nokia are the top selling mobile phones on JD.com during the 618 shopping festival

- MSP430 ADC analog-to-digital conversion program

- Qorvo Launches Two High-Performance PMICs for Data Center, Cloud Storage and Computing Applications

- Bridge rectifier circuit

- Matter Development Guide (IV): Building the Matter Compilation Environment

- Comparison table of dielectric constants of RF microwave high frequency plates

- Software Debugging Practice

TC52N4630ECTRT

TC52N4630ECTRT

京公网安备 11010802033920号

京公网安备 11010802033920号