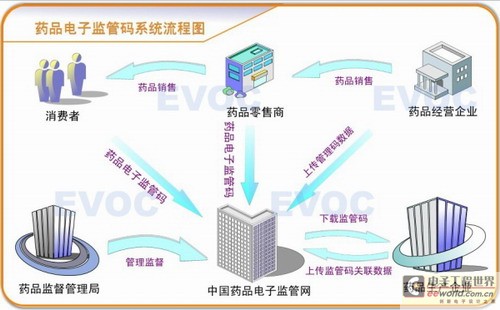

The electronic supervision code for drugs is a specific application of the concept of the Internet of Things. The electronic tag assigns a unique electronic supervision code to each smallest package of drugs, realizing "one code for one item" management, and collecting the dynamic information of drug production, circulation, use, etc. corresponding to the supervision code into the database in real time. Through a seamless network covering the whole country, a super-large database supporting tens of trillions of products of millions of enterprises and a professional customer service center, it provides information technology guarantee for the government to establish electronic archives for quality supervision from the source, track and trace the market, request certificates and invoices, implement incoming inspection and acceptance, establish electronic purchase and sales ledgers, and recall problematic drugs. Finally, an electronic supervision chain for the entire process of drugs from raw materials entering the factory, production and processing, factory sales to after-sales service has been established, and an electronic supervision chain for the entire process of drugs from planting and breeding, production and processing, circulation and sales to use has been established, providing an information technology platform for the establishment of a traceability and accountability system for drug quality and safety, and an electronic supervision network for drug quality covering the whole society has been established.

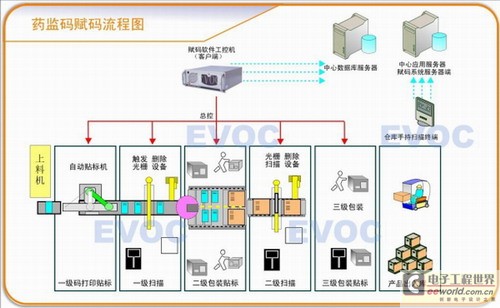

The drug supervision code data collection system can print labels on site or in advance during primary packaging. During secondary packaging, the drug supervision code of the primary packaging is scanned, and the system automatically counts according to the pre-set packaging specifications. When the number reaches the packaging specification, the system drives the barcode printer to print the secondary packaging code, and then packages and affixes the barcode. If there is a next-level packaging according to the packaging specification, the same packaging procedure is entered to perform a higher-level packaging operation. If the highest level of packaging specified in the packaging specification is reached, the packaging is prompted to be offline. In each layer of packaging, the upper-level packaging supervision code is automatically associated with the corresponding scanned lower-level supervision code. The packaging supervision codes of each layer of each largest package are associated as a whole through layer-by-layer association. The corresponding upper-level code or lower-level code can be queried in the system through any packaged supervision code.

The drug supervision code hardware system consists of a server, a printing PC , a flat labeling machine, an on-site industrial control computer, a drug supervision code scanner, a barcode printer, etc. In addition, the existing equipment needs to be modified according to the implementation of the system.

Based on the characteristics of the industry, the following requirements are put forward for the drug supervision code hardware system:

1. Diversified hardware peripherals: The drug supervision code assignment system consists of a variety of hardware devices, mainly including handheld, fixed, laser, barcode, label and other coding/scanning devices, all of which need to be connected to the coding industrial computer;

2. High stability and reliability: The system is used in the production line of a pharmaceutical factory, and general operators do not have professional computer maintenance capabilities. At the same time, the working status of the coding industrial computer directly affects the production process of the production line.

[page]

The specifications of EVOC EPX series product EIC-2403 are as follows:

Dimensions: 177mm(H)×482mm(W)×452mm(D)

CPU: Core?2 Duo 2.4G/2.5G/2.6G/2.8G/3.0G (optional)

Memory: 2G/4G (optional)

Hard disk: 500G/1T (optional)

Optical drive: 18xDVD (optional)

Standard I/O: 2 RS-232 serial ports, 8 (16 optional) RS-232/422/485 serial ports, 4 USB, PS/2

Digital I/O: (optional)

Bottom plate: compatible with 13-slot and 14-slot bottom plates

Front panel: with LCD screen, real-time temperature monitoring and power hard disk operation status display

Power supply: Support PS/2 specification power supply

Others: Two anti-vibration strips are used to prevent vibration

Structure: Safety door with lock to protect control components, keyboard interface at the front and back of the whole machine

This product, which is professionally used in the drug supervision code assignment system, has several advantages:

1. EVOC's unique EPI bus and its interface use European connectors to replace the gold finger connection method, 360-degree contact, sealed and dustproof, solid structure, vibration resistance, and can withstand a certain gravity to ensure a stable and firm connection;

2. Excellent air intake and heat dissipation design, real-time monitoring of the whole machine temperature;

3. Rich expansion, fully satisfying the stable and convenient access of multiple coding/scanning devices such as handheld, fixed, laser, barcode, and label on-site control;

4. Support truly high-performance dual-gigabit networks, providing a good network environment for coding application/issuance.

In short, the EPI bus products developed by EVOC for high-reliability sites can comprehensively improve the problems of gold finger oxidation, deformation, dust, etc. caused by long-term use of traditional industrial control products. The European connector is used to replace the gold finger connection method, with 360-degree contact, sealed and dustproof, solid structure, anti-vibration, able to withstand a certain gravity, and ensure stable and firm connection. At the same time, this series of products has rich expansion capabilities, the whole machine supports PCI2.3 specifications, and is compatible with the customer's original function board, achieving a steady improvement in the overall system security performance and stability.

Previous article:Key technologies to accelerate the development of mobile healthcare systems

Next article:MCU-based intelligent injection device can realize intelligent iontophoresis therapy

Recommended ReadingLatest update time:2024-11-17 02:45

- Popular Resources

- Popular amplifiers

-

Radio Frequency Identification (RFID) System Technology and Application (Written by Ci Xinxin, Wang Subin, and Wang Shuo)

Radio Frequency Identification (RFID) System Technology and Application (Written by Ci Xinxin, Wang Subin, and Wang Shuo) -

Introduction to Internet of Things Engineering 2nd Edition (Gongyi Wu)

Introduction to Internet of Things Engineering 2nd Edition (Gongyi Wu) -

A review of learning-based camera and lidar simulation methods for autonomous driving systems

A review of learning-based camera and lidar simulation methods for autonomous driving systems -

Computer Vision Applications in Autonomous Vehicles: Methods, Challenges, and Future Directions

Computer Vision Applications in Autonomous Vehicles: Methods, Challenges, and Future Directions

- High-speed 3D bioprinter is available, using sound waves to accurately build cell structures in seconds

- [“Source” Observation Series] Application of Keithley in Particle Beam Detection Based on Perovskite System

- STMicroelectronics’ Biosensing Innovation Enables Next-Generation Wearable Personal Healthcare and Fitness Devices

- China's first national standard for organ chips is officially released, led by the Medical Devices Institute of Southeast University

- The world's first non-electric touchpad is launched: it can sense contact force, area and position even without electricity

- Artificial intelligence designs thousands of new DNA switches to precisely control gene expression

- Mouser Electronics provides electronic design engineers with advanced medical technology resources and products

- Qualcomm Wireless Care provides mobile terminal devices to empower grassroots medical workers with technology

- Magnetoelectric nanodiscs stimulate deep brain noninvasively

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- Rambus Launches Industry's First HBM 4 Controller IP: What Are the Technical Details Behind It?

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- LM3630A overcurrent abnormality detection problem

- I would like to invite the great moderator eric_wang to answer what the northbound and southbound often used in NB-IOT mean

- 9-channel LED (light-emitting diode) drive control dedicated circuit

- 【EVAL-M3-TS6-665PN】Development Board Evaluation (1)

- 【UFUN Learning】Chapter 4 Chip ID

- I have received the acceptance notice, but I don’t know when the court session will begin. What should I do?

- Please explain the principle of this boost circuit

- Find a book specifically about C++ move semantics

- Career Options

- ST BlueNRG-LP Evaluation Board DesignSpark Unboxing

Radio Frequency Identification (RFID) System Technology and Application (Written by Ci Xinxin, Wang Subin, and Wang Shuo)

Radio Frequency Identification (RFID) System Technology and Application (Written by Ci Xinxin, Wang Subin, and Wang Shuo)

京公网安备 11010802033920号

京公网安备 11010802033920号