Groundbreaking Quad-Row Board-to-Board Connector Now Commercially Available

• The world’s smallest board-to-board connector is ideal for space-constrained smartphones, smartwatches, wearables, and augmented reality/virtual reality devices

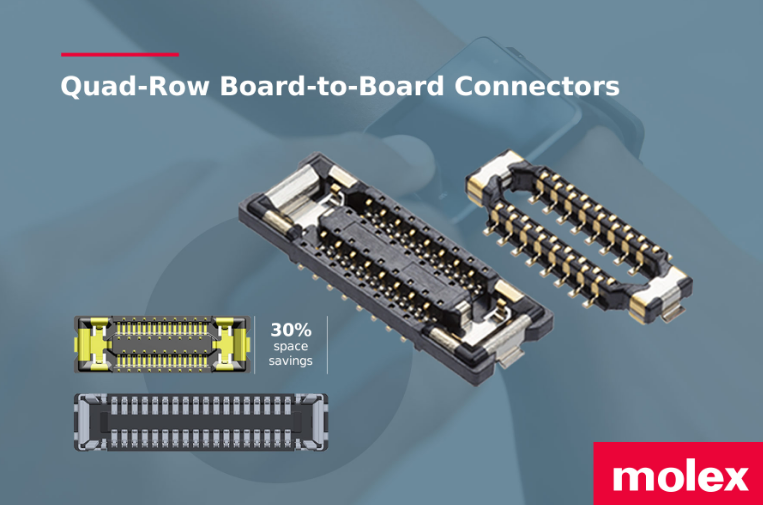

• Staggered circuit layout saves 30% space compared to traditional connector design

• Robust features enhance more reliable performance

• More than 50 million units shipped since 2020, supporting a major smartwatch manufacturer

Lisle, IL – June 23, 2022 – Molex, a global electronics leader and connectivity innovator, today announced the commercial availability of Molex Quad-Row Board-to-Board Connectors , which feature an industry-first staggered circuit layout that saves 30% space over traditional connector designs. These patent-pending connectors provide product developers and device manufacturers with greater freedom and flexibility to support compact form factors, including smartphones, smartwatches, wearables, gaming consoles, and augmented reality/virtual reality (AR/VR) devices.

“Molex continues to drive connectivity innovation to enable smaller, more powerful devices,” said Justin Kerr, vice president and general manager of Molex’s Micro Solutions business unit. “With the highly dense Quad-Row board-to-board connector, our customers can now squeeze more features, sensors and functionality into tighter and tighter spaces without compromising device performance. As a result, Molex is setting a new connectivity standard for space optimization.”

The first staggered circuit layout brings unprecedented space savings

Molex's long-term collaboration with product developers at a major smartwatch manufacturer led to the initial design of the Quad-Row board-to-board connector. Molex engineers also worked with experts at a global leader in the design, development and manufacture of flexible printed circuits (FPCs). The engineering teams worked together to verify the pioneering staggered circuit layout, arranging four rows of pins with a signal contact pitch of 0.175 mm. The result is unprecedented space savings while achieving high-density circuit connections.

The Quad-Row board-to-board connector adheres to a 3.0A current rating, meeting customer requirements for high power in a compact structure. In addition, the product meets the standard soldering pitch of 0.35 mm and uses typical surface mount technology (SMT) processes to speed up mass production. Thanks to the internal armor and inserted power pins, strong and reliable performance is ensured, protecting the pins from damage during mass manufacturing and assembly. These features, coupled with a wide array, facilitate quick and safe engagement and reduce the rate of shedding.

Mass production, diverse application portfolio

Since 2020, more than 50 million Quad-Row connectors have been shipped to support the production of the world's best-selling smartwatches. Molex's meticulous attention to manufacturing design has accelerated mass production. The connector also supports larger reel sizes, which can improve production efficiency and thus increase production yields.

In addition, the Quad-Row board-to-board connector is compact in size and reliable in performance, making it ideal for a variety of applications that require smaller and smaller printed circuit boards and flexible components. Because it can meet the needs of product miniaturization, it can create unlimited opportunities for augmented reality/virtual reality, automotive, communications, consumer, defense, Internet of Things, medical and wearable applications.

Availability

Molex Quad-Row board-to-board connectors are available globally in 32- and 36-pin configurations, with 20- and 64-pin configurations coming soon. Support for up to 100-pin configurations is also planned.

Molex Consumer and Commercial Solutions

Molex has proven expertise in 5G, mmWave, RF, signal integrity, antennas, power, cameras and display technologies , providing critical connections for the entire mobile device ecosystem. Advantages such as precision, volume manufacturing and miniaturization enable Molex to meet changing market demands and provide leading mobile device manufacturers and their suppliers with the smallest, densest and most advanced connectors currently available on the market.

Previous article:HARTING Technology Group returns to Hannover Messe 2022 after two years

Next article:Melexis launches innovative Hall switch for liquid level detection applications

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- AD18, keepout options are all grayed out, and I can't use keep out wiring. What should I do?

- [Raspberry Pi Pico Review] Simple test of power on with uf2 file

- [NXP Rapid IoT Review] + NXP Rapid IoT interface design process

- Basic Considerations for Sensors in Powertrain Systems

- How do I calculate the capacity of the supercapacitor I need?

- After staying up late to sort it out, here is the information of the electric cars on the national competition list

- Have you ever experienced the dreaded “drinking culture”? How did you deal with it?

- Analysis of 2017 Signal Source Competition Topic

- [RVB2601 Creative Application Development] LVGL Display Library Test

- GD32F3 Advanced Development Tutorial——Based on GD32F303ZET6 Data Package

MOLEX connector

MOLEX connector Altium 15 latest device library: Molex_220709.rar

Altium 15 latest device library: Molex_220709.rar Molex Incorporated releases Impel high-speed backplane connector system for use with its backplane pin map configurator

Molex Incorporated releases Impel high-speed backplane connector system for use with its backplane pin map configurator

京公网安备 11010802033920号

京公网安备 11010802033920号