As the main medium- and short-distance means of transportation in China, the number of electric two-wheelers in the Chinese market has exceeded 300 million by 2020. This is a very large market, and it can be said that almost every household has an electric two-wheeler. In view of such a huge market application, this article will introduce TI's typical BMS solutions.

Although lithium batteries have higher energy density and cost-effectiveness than lead-acid batteries, and will become the mainstream of electric two-wheeled vehicles driven by the new national standard, it cannot be ignored that lithium batteries are more dangerous than lead-acid batteries. If not treated with caution, fire, explosion and other dangers are likely to occur. Therefore, this also puts higher requirements on BMS solutions.

TI provides competitive BMS solutions for electric two-wheeled vehicles powered by lithium battery packs. According to the number of battery strings, we can roughly divide electric two-wheeled vehicles into two categories: electric bicycles (≤16S) and electric motorcycles (>16S).

Electric bikes

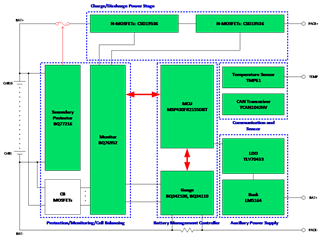

Electric bicycles usually have battery packs of 16S or less. Taking a 16S electric bicycle battery pack as an example, the following figure is a typical BMS solution based on TI products. The key components use TI's latest products, which have lower costs and higher performance, helping everyone achieve a better BMS design.

Wide output range DC converter output characteristics

From a structural point of view, we can roughly divide it into 5 parts:

-

Battery monitoring and protection

-

Battery Management and Control

-

Charge and discharge power path

-

Communications and Sensing

-

Auxiliary power supply

The following is an introduction to the key components of each part:

Battery monitoring and protection

This part mainly includes the analog front end and secondary protection chip. This part is mainly to monitor and protect each battery to prevent the battery from exceeding the safe working area and causing danger.

Analog front end: BQ76952

BQ76952 is TI's latest generation of high-string analog front end, which supports 3-16 string applications. The same series of products also include BQ76942 and BQ769142, which support 3-10 string and 3-14 string applications respectively. Users can choose according to actual needs. BQ769x2 integrates primary protection for various fault conditions such as overvoltage, undervoltage, overtemperature, overcurrent, and short circuit. Supports multiple communication methods such as I2C, SPI, and HDQ. Integrated internal battery balancing, and also supports external balancing. In addition, BQ769x2 also supports out-of-order power-on, which greatly saves production line assembly time and cost. The integrated high-side driver can save a driver IC—BQ76200 for high-side protection applications compared to the previous generation product BQ769x0. And BQ76952 can not only be used with MCU, but also can be separated from MCU and run independently, which is suitable for low-cost applications.

Secondary protection: BQ77216

In order to prevent the battery pack from being in a dangerous situation without protection due to analog front-end failure, there is usually a secondary protection. When a serious fault occurs and the primary protection does not work, the secondary protection is activated and the fuse is blown to avoid danger.

BQ77216 is TI's latest secondary protection chip developed for electric two-wheeled vehicle applications. It is also the first and only secondary protection chip on the market that supports 16 strings as far as I know. Previous solutions have used several 5S second-stage protection ICs, such as BQ7718, plus some peripheral logic and resistors and capacitors for cascade use. The single-chip solution not only saves costs, but also simplifies the difficulty of design and layout, improves PCB utilization, and enhances reliability. BQ77216 has a variety of configurations to choose from. Users can choose the appropriate model according to actual needs. If there is no suitable model, you can contact the corresponding technical support for customization.

Battery Management and Control

This part mainly includes the power meter and microcontroller. For some low-end products, the voltage table lookup method is usually used to calculate the power. Although this method is simple, it is not very accurate. For mid-to-high-end products, the power meter is usually required to provide more accurate power calculation and display. And in most cases, it needs to work with the MCU to achieve battery replenishment management and external information exchange.

Fuel gauge: BQ34Z100

The BQ34Z100 is a fuel gauge solution that works independently of the battery cell series configuration. It supports 3V to 65V batteries through an external voltage conversion circuit, which can be automatically controlled to reduce system power consumption. The BQ34Z100 device provides several interface options, including an I2C slave interface, an HDQ slave interface, one or four direct LED interfaces, and an alert output pin. In addition, the BQ34Z100 provides support for external port expanders (supporting more than four LEDs).

Processor: MSP430FR2155DBT

MSP430FR215x microcontrollers (MCUs) are all part of the MSP430MCU Value Series, an ultra-low power, low-cost device product line that combines unique embedded FRAM with an overall ultra-low power system architecture to reduce energy consumption while ensuring performance. They are suitable for battery-powered applications, saving power and extending battery life.

Charge and discharge power path

The charging and discharging power tube can be selected according to the actual needs of voltage, current, etc., and this article will not go into details.

Communications and Sensing

This part mainly includes CAN communication transceiver and thermistor.

CAN communication transceiver: TCAN1042HV

This CAN transceiver family complies with the ISO1189-2 (2016) high-speed CAN (Controller Area Network) physical layer standard. All devices are designed for CAN FD networks with data rates up to 2Mbps (Megabits per second). There is an auxiliary power input for I/O level translation (used to set input pin thresholds and RXD output levels). The family features a low-power standby mode and remote wake-up request feature. In addition, all devices include many protection features to improve the stability of the device and CAN.

Thermistor: TMP61

The TMP61 linear thermistor provides linearity and consistent sensitivity over the entire temperature range, enabling a simple and accurate method for temperature conversion. The low power consumption and small thermal mass of the device minimize the effects of self-heating. With built-in high temperature failure protection and strong resistance to environmental changes, these devices are designed for long-life, high-performance applications. The small form factor of the TMP6 series devices also allows for placement close to heat sources and fast response time.

Advantages over NTC thermistors include no additional linearization circuitry, minimized calibration, smaller resistance tolerance variations, higher sensitivity at high temperatures, and a simplified conversion method that saves processor time and memory.

Auxiliary power supply

BQ769x2 integrates two configurable output LDOs. However, for high-voltage and high-current applications, considering the heat dissipation problem caused by the high voltage difference, a high-efficiency DC-DC power chip is still needed to convert the battery high voltage into a relatively low voltage, such as 5V, and then use an LDO to convert the DC-DC output into a low-noise power rail to power the MCU.

DC-DC:LM5164

Because it is a battery application, in order to maximize the battery life, the static power consumption of the chip is required to be high. The no-load static current of LM5164 is extremely low, only 10.5uA, which can save battery power to the maximum extent and extend battery life. In addition, LM5164 supports a maximum input voltage of 100V, providing a safe withstand voltage for 16-string applications. The COT mode control architecture adopted has a faster transient response speed.

LDO: TLV70433

The TLV704 series LDO has an extremely low quiescent current of only 3.2uA. In addition, the quiescent power consumption is basically constant over the full temperature and full load range, making it an ideal power supply for low-power microcontrollers such as MSP430.

Electric motorcycle

The solution for electric scooters is basically similar to that for electric bicycles. The main difference between electric scooters and electric bicycles is that the number of strings for electric scooters is usually more than 16, with 17, 20 and 24 being common. Because of the increase in the number of strings, the single BQ76952 used in the solution for electric bicycles cannot meet the demand. This requires two BQ769x2s to be cascaded, and the same BQ77216 also needs to be cascaded. And after the cascade, an isolated I2C is also needed for isolated communication between the two BQ769x2s.

Isolated I2C: ISO1640

The ISO164x series is TI's latest I2C isolator with a higher cost-performance ratio. It supports hot-swap, low-power bidirectional I2C isolators. It meets the UL 1577 standard, has passed UL, CSA, CQC, VDE, TUV certification, and supports 1.7MHz bidirectional transmission rate.

Previous article:Renesas Electronics, high voltage, battery cells, batteries, front-end products

Next article:Practical information | The most comprehensive analysis in history: the functional circuits of switching power supplies

Recommended ReadingLatest update time:2024-11-16 11:33

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- HuaDa HC32F460 series MCU internal FLASH made into USB flash drive

- PCB wiring and layout and circuit design 268 design specifications

- [ESK32-360 Review] + Construction of development environment

- Several circuit designs that must be understood by microcontrollers

- Share an article I read about PLL integer boundary spurs by IDT (Renesas)

- I can't read the TMP275 temperature sensor. I use the STM32 I/O to simulate IIC. Please help.

- Understanding GaN Device Thermal Analysis

- 5. Control objects in previous “Control” competitions

- Album of previous competition questions of the National Undergraduate Electronic Design Competition

- Explanation of the schematic diagram of the xenon lamp flash circuit

Tesla-Model-S-Battery Disassembly Report

Tesla-Model-S-Battery Disassembly Report

京公网安备 11010802033920号

京公网安备 11010802033920号