The industry is currently discussing "de-powering", which includes not using a power supply at all or removing some functional modules of the power supply. De-powering can also be done at different levels, including: at the chip level, at the electronic component level, and at the lamp level.

Current situation: Multiple patented technology routes using completely different principles have been proposed for de-electricalization at different levels.

Question: Is there a universal principle for reducing flicker that can be applied to all levels and a patented technical route based on this principle, without the need to develop different technical routes using different principles for different levels?

This article introduces a general principle for reducing flicker and a technical route based on this principle.

The characteristic of this technical route is that its principle can be applied to the chip level, electronic component level, and lamp/circuit level.

The following is a brief introduction to the general principles of reducing flicker.

To simplify the drawing and analysis, assume that:

(1) The waveform of the AC current after phase shifting remains unchanged and is still a sine wave. Although the waveform changes after phase shifting, it does not affect the general principle of reducing flicker. It only needs to adjust the phase difference between the different input AC currents to achieve the desired result;

(2) Within the operating current range, the luminance is basically proportional to the current (Lumileds). Therefore, although the following analysis is only about the current, the conclusions apply to the luminance.

As we all know, the impact of flicker on the human eye mainly depends on the difference between the maximum and minimum brightness (percent flicker) and the oscillation frequency of the maximum value.

The general basic principle is: input AC currents of different phases, rectify them separately and add them together to form a total current, and use the total current to drive the LED lamps. The result is:

(1) The oscillation frequency of the maximum value of the total current increases, and therefore, the oscillation frequency of the maximum value of the light brightness increases;

(2) The difference between the maximum and minimum values of the total current decreases, so the percentage flicker of the brightness decreases;

(3) There is no moment when the total voltage after superposition is equal to 0 (or less than 2.8V). Therefore, there is no moment when the lamp does not emit light.

Therefore, the flicker of the brightness of the LED lamp driven by the total current is reduced to the same level as or even better than that of other lamps, that is, this principle can meet the flicker requirements for the lamp.

Here are a few examples to illustrate how the general principle of reducing flicker is used to reduce flicker.

An input sinusoidal AC current: The normalized waveform after rectification is as follows (Figure 16):

For two input sinusoidal AC currents with a phase difference of 90°: after rectification separately but without superposition, the normalized graphs of the two pulsating DC currents are shown in Figure 17:

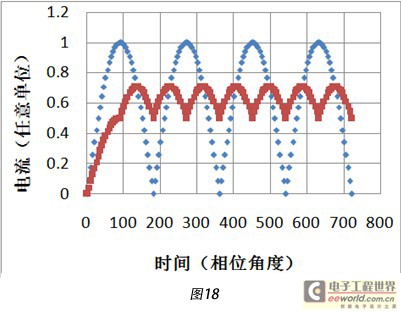

The pulsating DC currents obtained by rectifying the two input sinusoidal AC currents with a phase difference of 90° shown in Figure 17 are superimposed to obtain the total current. The waveform of the normalized total current is shown in Figure 18 (the maximum value of the total current after rectifying and superimposing the two input sinusoidal AC currents with no phase difference is 1).

In order to demonstrate the function of the general principle of reducing flicker, a comparison is made: in Figure 18, the diamond () represents the normalized total current after two sinusoidal alternating currents with no phase difference are rectified and superimposed, and the square () represents the normalized total current after two sinusoidal alternating currents with a phase difference of 90° are rectified and superimposed (the maximum value of the total current after the two sinusoidal alternating currents with no phase difference are rectified and superimposed is 1).

In order to demonstrate the function of the general principle of reducing flicker, a comparison is made: in Figure 18, the diamond () represents the normalized total current after two sinusoidal alternating currents with no phase difference are rectified and superimposed, and the square () represents the normalized total current after two sinusoidal alternating currents with a phase difference of 90° are rectified and superimposed (the maximum value of the total current after the two sinusoidal alternating currents with no phase difference are rectified and superimposed is 1).

For three input sinusoidal alternating currents with phases of 0°, 60°, and 120° respectively: the waveform of the normalized total current after rectification and superposition is shown in Figure 19 (the maximum value of the total current after rectification and superposition of three input sinusoidal alternating currents with no phase difference is 1):

In order to demonstrate the function of the general principle of reducing flicker, a comparison is made: in Figure 19, the diamond represents the normalized total current after three sinusoidal alternating currents with no phase difference are rectified and superimposed, and the square represents the normalized total current after three sinusoidal alternating currents with a phase difference of 60° are rectified and superimposed.

Figures 18 and 19 clearly show:

(1) The difference between the maximum and minimum values of the total current after the input AC currents of different phases are rectified and superimposed is reduced, so the percentage flicker of the brightness generated by the total current is reduced;

(2) The oscillation frequency of the maximum value of the total current and the brightness of the light generated increases;

(3) There is no moment when the total current and the brightness of the light generated are zero.

Therefore, the influence of the general strobe on the human eye is reduced.

If the number of input AC currents is continued to increase, for example, AC currents with 4 phases of 0°, 45°, 90°, and 135°, or even AC currents with 8 phases of 0°, 22.5°, 45°, 67.5°, 90°, 112.5°, 135°, and 157.5° are input, and then rectified and superimposed, the difference between the maximum and minimum values of the total current is further reduced, and therefore, the percentage flicker of the brightness generated is further reduced; the oscillation frequency of the total current and the maximum value of the brightness generated is further increased.

18 and 19 , four alternating currents with a phase difference of 45°, and eight alternating currents with a phase difference of 22.5° are analyzed, and the results shown in FIG. 20 are obtained.

In FIG20 , the diamonds represent the percentage of the minimum value to the maximum value of the total current superimposed after rectification (the right vertical axis), and the squares represent the oscillation frequency of the maximum value of the total current superimposed after rectification (the left vertical axis).

Taking 50Hz alternating current as an example, after rectification, the oscillation frequency of the maximum value of the pulsating current is 100Hz.

Figure 20 shows:

1) For two input AC currents with a phase difference of 90°, the minimum value of the total current after rectification is 70% of the maximum value, and the oscillation frequency of the maximum value is greater than 200Hz. Therefore, the percentage flicker of the light brightness generated by the total current = 18%. This is better than the percentage flicker of 28% of fluorescent lamps using magnetic ballasts (Figure 13b).

2) For the three input AC currents with phase angles of 0°, 60°, and 120°, the minimum value of the total current after rectification is more than 85% of the maximum value, and the oscillation frequency of the maximum value is close to 400Hz. Therefore, the percentage flicker of the brightness generated by the total current = 8%. It reaches the level of 8% of the percentage flicker of an incandescent lamp (Figure 14b).

3) For the input AC currents with four phase angles of 0°, 45°, 90°, and 135°, the minimum value of the total current after rectification is more than 90% of the maximum value, and the oscillation frequency of the maximum value is close to 500Hz. Therefore, the percentage flicker of the light brightness generated by the total current = 5%. This reaches the level of 5% (Figure 15b) of energy-saving lamps using electronic ballasts.

4) The more the number of AC currents input, the smaller the corresponding phase difference angle, the closer the ratio of the minimum value to the maximum value of the total current superimposed after rectification is to 1, and the greater the oscillation frequency of the maximum value. Therefore, the smaller the percentage flicker of the brightness generated by the total current, the greater the oscillation frequency of the maximum brightness, and the smaller the impact of flicker on the human eye.

The percentage flicker is calculated according to the formula of Energy Star (Figure 21).

Previous article:Technical Discussion: Typical Analysis of Failure Mechanisms of LED Lighting Driver Circuits

Next article:Advantages of various switching power supply topologies for LED driving and dimming

Recommended ReadingLatest update time:2024-11-16 15:19

- Popular Resources

- Popular amplifiers

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- TI Texas Instruments CCD

- Design scheme based on embedded processor PowerPC7447

- [Xiao Meige SoC] How to turn off the LED flashing when AC501-SoC development board is turned on in the default Linux system

- There are some problems with this flyback power supply circuit

- 2. Reading and demonstration of all sensor data based on Nucleo-L476L

- Application of siwave in single board PI design

- I would like to ask, the output waveform of the power amplifier is more than 180 degrees out of phase with the input waveform. What is going on?

- AD+FPGA+asynchronous FIFO+CMI+SPI code

- Using FSMC bus for inter-chip communication

- I'm a newbie. I don't understand. I'm asking for help on the problem I encountered when making a spi receiving module in Verilog.

Siemens PLC Project Tutorial

Siemens PLC Project Tutorial LED Cube Code

LED Cube Code ESP32-S3 source code

ESP32-S3 source code

京公网安备 11010802033920号

京公网安备 11010802033920号