Since 2010, the U.S. Environmental Protection Agency (EPA) and the Department of Energy (DOE) have successively issued Energy Star and Lighting Facts standards for LED light source lamps/bulbs, so that related industries can follow the specifications of LED lighting products. Currently, international LED manufacturers also use this as a basis for life assessment and product specifications of LED products. In other words, if LED manufacturers want to enter the international LED lighting market, they must obtain the LED Energy Star certification.

In the Energy Star area, on July 6, 2011, EPA integrated the two major types of lighting standards, residential lighting (RLF) and solid-state lighting (SSL Luminaires), into [ENERGY STAR? Luminaires Program Requirement V1.1] in order to simplify the qualification review process, and set it to be officially implemented on April 1, 2012. In addition, the light bulbs were also integrated into [ENERGY STAR? Program Requirements for Integral LED Lamps V1.4]. In addition to the increase in the data items to be reviewed in the two standards, the requirements of [LM-82 Photoelectric Characteristics Specification] and [TM-21 Life Estimation Specification] have been included in them, which has caused more discussion.

LM-82 has not yet been officially published by the Illuminating Engineering Society of North America (IESNA). Its content mainly covers the characteristic verification method of the electrical and optical properties of LED Light Engines and Integrated LED Lamps at different temperatures. Its measurement method is similar to the LM-79-08 plan, but the focus is on the evaluation of the characteristic impact of temperature on electrical/optical parameters.

The other part is TM-21-11 (Projecting Long Term Lumen Maintenance of LED Light Sources) published by IESNA on July 25, 2011. This specification is mainly aimed at predicting the performance and life of LED light sources, and is linked to the recently announced LM-80-08 LED lumen maintenance test. The experimental data of LM-80-08 is used to estimate the long-term life performance of LED components and lamps/bulbs.

1. Steps for estimating LED lamp life using TM-21 In order to help LED industry players have a clearer understanding of TM-21 and how to use TM-21 to estimate LED products, the author will explain the application and estimation methods of LM-80-08 and TM-21-11 in four steps:

Step 1: The LED component supplier conducts LM-80-08 experiments on its LED Source (Package/Array/Module) at three temperatures (55℃/85℃/selected temperature) for at least 6,000 hours.

★ Sample quantity requirement: (related to the estimated time)

★ Test time requirement: (related to estimation accuracy) at least 6,000 hours, 10,000 hours is recommended. The LED light decay data needs to be obtained every 1,000 hours. The shorter the interval (eg 500 hours), the higher the estimation accuracy.

Step 2 : Estimate the long-term life data at three test temperatures (55°C/85°C/selected temperature) based on the TM-21-11 formula.

★ Get the average value of each temperature experimental data. The test data extraction time rule is:

★ Obtain the slope using Exponential Least Squares Curve-Fit

m (Slope) and intercept b (Intercept). When calculating m and b, the longer the test time and the denser the interval, the higher the accuracy will be. Then calculate the B and α values.

![]()

★ Use the following formula to calculate the LED lifespan at each temperature test when the lumen maintenance rate is 70% of the ENERGY STAR requirement.

L70: The usage time when the LED lumen maintenance rate is 70%

★ Based on the number of samples in step 1, the standard judgment of the estimated multiple time is:

The representation is:

(6K): LM-80 test time, (6K) = 6,000 hours; (10K) = 10,000 hours

XX, XXX Hours: Sample ≧20ea, test time = 6,000, which can be estimated 6 times to be 36,000 hours

★ Use the Exponential formula to calculate the lumen maintenance rate at each time, and then use the calculated data to draw an estimated life curve for each test temperature:

Step 3: Obtain the in-situ temperature of the LED component placed in the LED lamp.

★ Please refer to the ISTMT (In Situ Temperature Measurement Test) test procedure to obtain the temperature of the LED component placed in the LED lamp. The test temperature position must be the same as the Ts setting position of LM-80-08. The temperature data obtained is called TMPLED (LED Temperature Measurement Point).

Step 4: Perform interpolation calculations using the measured TMPLED and the results of TM-21 calculations to obtain the estimated lifespan of the TMPLED.

★ Select the two temperature points closest to the TMPLED coating from the three test temperature points as the calculation reference points.

★ Calculate the Arrhenius ModEL temperature acceleration parameter A and obtain the Decay Rate: α and the constant parameter B0.

★ Use the above formula to calculate the L70 value of TMPLED. The same procedure is used to express the results of TMPLED.

★ Input the relevant time values and draw a life estimation chart of TMPLED and the three Ts.

2. ENERGY STAR / Lighting Facts requirements for LED lamps / bulbs life

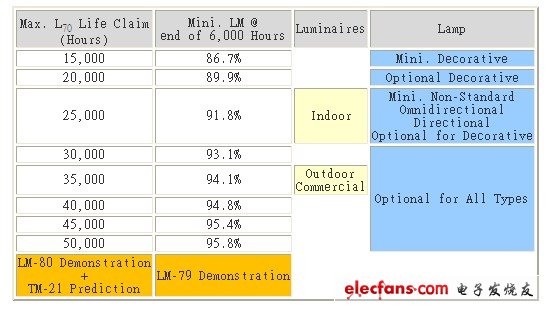

ENERGY STAR has only two specifications for lamps. Lamp manufacturers can use the whole lamp to light up for 6,000 hours, or submit the component manufacturer's 6,000 hours LM-80 report and TM-21 estimation results to verify the lumen maintenance rate of the finished lamp. The standard for the bulb part is more flexible, and the standard will be fine-tuned for different uses, as shown in the following table:

3. The key to success in the highly competitive LED lighting industry: LED quality

Lighting products are considered the biggest business opportunity for LEDs. However, in the past, LEDs were too expensive. Although they have advantages such as energy saving and environmental protection, their prices are still not competitive with incandescent and energy-saving bulbs. In addition, in the past few years, due to the lack of relevant quality verification standards, the quality of LEDs varied (light decay problems, color change problems, etc.), which also led to many negative user experiences and delayed the explosive growth of LED lighting usage.

However, in 2012, the sweet spot of LED lighting prices has arrived ahead of schedule, and it is expected that the demand for LEDs will increase significantly in the next two years. When the price of LED products reaches a price that consumers can accept, whether LED manufacturers can stand out from the crowd and be favored by consumers during this wave of demand increase will depend on the quality and life of LEDs.

Therefore, seeking assistance from a professional laboratory is definitely one of the fastest ways to improve quality and market competitiveness.

Previous article:Comprehensive understanding of LED lighting LED light source issues

Next article:Summary of LED lamp driver power design experience

Recommended ReadingLatest update time:2024-11-16 22:45

- Popular Resources

- Popular amplifiers

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- A lightweight and precise positioning algorithm based on multiple inertial measurement units (LSM6DSOX)

- PT1000 circuit help

- Brief analysis of the working principle of DSP

- The national competition is tomorrow. What are you doing today?

- Looking for asm330lxh driver!!!

- Share post: Just completed FPGA interpolation filter design

- Introduction to Common PCB Microvia Technology

- Analysis of the design principle of single chip microcomputer music program

- Beetle_ESP32-C3 Arduino routine learning

- [BearPi-HM Nano, play Hongmeng's "touch and pay" function] Part 4: Combination of OLED and UDP!

Siemens PLC Project Tutorial

Siemens PLC Project Tutorial LED Cube Code

LED Cube Code ESP32-S3 source code

ESP32-S3 source code

京公网安备 11010802033920号

京公网安备 11010802033920号