Development and Trend of Lighting Technology

History of Lighting Development

First, reviewing the development history of lighting technology, the first generation is represented by incandescent lamps, which have the advantages of low price and good low-temperature starting characteristics, but short life and low luminous efficiency. The second generation is represented by fluorescent lamps, which have long life, high luminous efficiency and low cost, but the disadvantages are that they contain heavy metal mercury and the ballast/starter has high power consumption. The third generation is represented by high-pressure gas light sources, which have the advantages of strong penetration and high reflectivity, but contain heavy metal mercury, low color rendering, and need to install a rectifier. LED belongs to the fourth generation of lighting equipment, which has low working voltage, safety and energy saving, low maintenance cost and long life. The main problem at present is high price and high heat generation. It should be pointed out that there is no manufacturer corresponding to the recycling of metal mercury in lamps, but LED does not contain mercury.

Lighting market trend

Lighting accounts for a large proportion of household/commercial electricity consumption, about 17%. Large consumption causes problems such as waste of resources, carbon dioxide emissions and global warming. Therefore, the demand for green and energy-saving lighting systems is gradually increasing worldwide. With the development and improvement of lighting sources, lighting power consumption is gradually reduced, and the power consumption of LED is only 1/8 of that of incandescent lamps. At the same time, the lighting system adopts intelligent lighting control systems with various communications and sensors to improve application efficiency.

Japan launched the "21st Century Lighting" plan in 1998, aiming to increase the energy efficiency of lighting to twice that of traditional fluorescent lamps through LED technology. South Korea, the European Union, and the United States have also proposed their own lighting plans. China has a number of national standards and industry standards related to semiconductor lighting that are about to be issued, and the Ministry of Finance is brewing relevant support policies for semiconductor lighting. The pace of government procurement of semiconductor lighting demonstration projects is accelerating.

Figure 1 Future lighting innovation

Modern LED lighting demand for MCU General

LED lighting market classification can be roughly divided into the following categories: indoor lighting, commercial lighting, automotive lighting, outdoor lighting, traffic signals, entertainment lighting, street lights and electronic display boards, LCD backlights, etc.

With the development of lighting demand and the deepening of energy conservation and emission reduction, future lighting innovation can be carried out from the perspectives of time-sharing control, ambient brightness sensors, motion sensors, heat management, etc.

The future lighting innovation market has great potential, as shown in Figure 1. Time-sharing control means having different brightness in different time periods. Ambient brightness sensors can flexibly respond to the brightness of the environment in which the lamp is located. For example, when it is cloudy, it gets dark earlier than usual, so the street lights will be turned on in advance. Motion sensor detectors mean that if there is no activity around the lamp at night, the brightness will be lowered, and when human activity is detected, the brightness will be increased. In addition, modern lighting requires multiple communication methods. In addition to wireless methods, advanced lighting-specific communication protocols such as DALI or DMX512 make the management of lamps more convenient, and power line carrier communication (PLC) has also attracted much attention in recent years. The

development direction of intelligent lighting

The development direction of intelligent lighting presents several development directions: the integration of MCU is improved, the required peripherals are reduced, and it is more environmentally friendly; LED meets the color mood of family scene dimming and is more humanized; various communication protocols facilitate the expansion of dimming systems and enhance scalability; wireless connection methods enable lighting communication to be integrated into smart homes and achieve integration. The popularization of smart homes can promote green and low-carbon life and protect the environment. Intelligent mixed color dimming requires scene lighting that supports wireless communication. The APPLILET HCD tool can facilitate the development and debugging of mixed color dimming, which is very practical.

Figure 2 Feedback control through comparator

Figure 3 Feedback control through A/D converter

Figure 4 LED constant current control operation flow chart (LED = 3 channels)

Requirements of modern LED lighting

Requirements for LED lighting include both domestic lighting and non-domestic lighting.

Domestic lighting:

(1) Longer working life

(2) Low cost and small size

(3) Low power consumption and high efficiency

(4) Compatible with existing systems

Non-domestic lighting:

(1) Low power consumption and high efficiency

(2) Multi-channel (6 channels or more)

(3) PFC control

(4) PLC communication/wireless communication

The demand for MCU is reflected in the following aspects:

• Accurately control current to extend the life of lamps

• Multiple protection functions to ensure the safety of lamps

• High integration, saving space and cost

• Flexible and precise dimming, less energy consumption for the same brightness.

• Provide independent timer threshold output function for multiple channels at the same time

• Diversified communication methods, support IR/wireless/DALI/ DMX512/ PLC/

• Higher operating temperature (85℃~105℃)

• More practical evaluation scheme

Demands of the lighting market

Combined with high dimming accuracy, low cost, energy saving and emergency protection functions, it is summarized as a single-chip MCU to achieve low-cost and high-performance green energy-saving lighting system.

Application of MCU in LED lighting

In response to the MCU needs of the entire lighting market, Renesas Electronics has launched corresponding MCUs.

78K0/Ix2

In response to these needs of the lighting market, Renesas Electronics' 78K0/Ix2 MCU products have solved these problems well. 78K0/Ix2 has many corresponding features. The PWM output period of 78K0/Ix2 is 25ns, with 16-bit variable frequency timer and internal 40MHz operating clock characteristics, which meets the needs of high-precision dimming. 78K0/Ix2 does not require peripheral ICs, and can be controlled by PFC IC, variable frequency control IC and LED driver IC (LED lighting), effectively reducing costs. The timer high impedance output in the emergency state is linked with the comparator/external interrupt. The corresponding method is to achieve "any brightness" and reduce energy consumption by using sensors/communication, and the communication includes DALI, DMX, remote control and I2C. The lighting ASSP microcontroller 78K0/Ix2 has a variety of memory capacities and pin counts to choose from, corresponding to simple to complex LED lighting applications.

Figure 5 Lighting reference solution

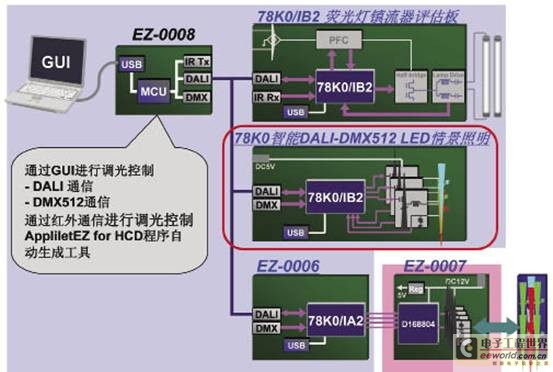

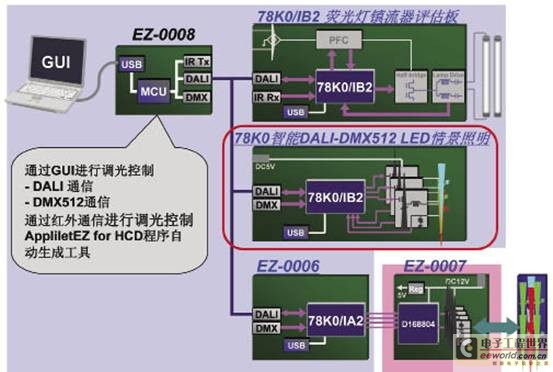

Figure 6 Intelligent DALI-DMX512 LED scene lighting control

Features of the lighting ASSP microcontroller 78K0/Ix2:

•Built-in high-speed crystal oscillator (CPU up to 20MHz)

•High-speed 4-channel 16-bit PWM timer (40MHz)

•Built-in on-chip debugging

•Serial communication (UART, I2C, CSI), built-in DALI (lighting communication) function

•MCU operating temperature can reach 105℃

•Can independently control up to 4 LEDs

•Can adapt to the use environment where LED lighting fixtures generate a lot of heat

•Can easily implement DALI protocol reception/transmission

Features of timers suitable for lighting control:

•Counting clock reaches up to 40MHz

• PWM output with dead time

• Full/half bridge control possible

• 4-channel synchronous output

• Emergency stop function linked to comparator

• LED constant current control possible with A/D converter

• Can be used as a switch signal for LED constant current control or as a dimming brightness control signal

Enhanced analog function:

• Timer synchronized A/D converter

• Built-in 1.2V regulated reference

• 3-channel comparator

• Built-in operational amplifier, including PGA mode (×4/×8/×16/×32), independent mode (using +/ -/ output pins)

• Can be used for fast response feedback operation of LED constant current control

• Can be used to detect tiny signals from sensors to control the brightness of LED lamps

Constant

current control There are two ways of constant current control.

The first is feedback control through comparator. Use comparator to detect LED current and realize constant current control by changing PWM output duty cycle. Independent dimming (28 levels) of each channel can be realized by changing the built-in reference voltage of comparator, as shown in Figure 2.

The second is to perform feedback control through the A/D converter, use the A/D converter to detect the LED current, and achieve constant current control by changing the PWM output duty cycle. Independent dimming of each channel is achieved by changing the target value of the A/D conversion, as shown in Figure 3. The LED

constant current control operation flow chart is shown in Figure 4. As shown in the figure, there are 3 channels of LEDs that need to be controlled, which is a repeated operation of A/D conversion → PWM output fine-tuning. The software operation process is to perform A/D conversion on the feedback resistor voltage of CH1, fine-tune the PWM wave duty cycle input to CH1, and then perform the same operation on channel 2 and channel 3, and repeat the above process. The entire cycle of A/D conversion and detection adjustment of the three channels is about 50μs.

Figure 7 78K0 driverless intelligent dimming LED bulb reference board

Figure 8 78K0/IB2 LED street light solution

Green LED lighting solution The

lighting reference solution of Renesas Electronics consists of 3 parts. Dimming control can be performed through the PC GUI. The PC and communication board are connected through a USB cable. The scene lighting board and the communication board can be realized by infrared, DALI and DMX512. In the lighting reference solution of Renesas Electronics, the AppliletEZ for HCD program automatic generation tool can be used to realize the involvement, compilation and burning of the lighting control program. The lighting reference solution is shown in Figure 5. Advantages

of 78K0/IB2 low-cost high-brightness LED dimming (color adjustment) control:

• 3-channel independent constant current control (high-brightness LED)

• Dimming control, color adjustment control

• Communication mode (DALI, DMX512, AD input)

Intelligent DALI-DMX512 LED scene lighting control is shown in Figure 6. Through the internal reference voltage/PWM duty cycle of the comparator, 3-channel independent LED dimming (28 levels) can be performed; through the synchronous control of the 8-bit PWM TMH1, the dimming accuracy can be further improved.

The 78K0 driverless intelligent dimming LED bulb reference board is shown in Figure 7. Ordinary incandescent lamps have high power consumption and low energy efficiency ratio of dimming. The 78K0 driverless intelligent dimming LED bulb reference board can achieve AC220V without PFC adjustment function; remote control dimming (custom 315M RF); small PCB is easy to integrate.

The LED street light solution based on 78K0/IB2 is shown in Figure 8. It can achieve AC220V with PFC; total driving power is 60W; the dimming communication interface can use RS485/PLC interface.

Development tools

The first step is to generate device drivers through the device driver automatic generation tool (Applilet2). The second step is to edit the program (integrated development environment) (source program management, editing, tool management) through Project Manager (PM+). The third step is debugging (ID78K0) and simulation. Operation confirmation is performed through MINICUBE2 (simple), IECube, etc. In addition, for mass production programming tools, in addition to the tools provided by Renesas Electronics, there are also third-party tools that can be supported. Renesas Electronics provides a lighting reference solution kit so that even if you are new to MCU, you can quickly get started.

Q&A Selection

Q: Can LED lighting achieve real-time brightness adjustment or external light control? How to achieve it?

A: Real-time brightness adjustment can be achieved, and external light control can be achieved by adding a brightness sensor.

Q: In actual operation, what principles should lighting design follow?

A: Lighting design should be people-oriented, but safety and practicality must be considered first, as well as illumination requirements, installation methods, and maintenance methods, and finally combined with humanized creativity. A good lighting design must have the above prerequisites.

Q: Please introduce how to implement the PFC function in the MCU?

A: The current solution uses a boost APFC, which implements PFC through the built-in comparator and PWM function of the MCU, without the need for peripheral IC.

Q: What is the prospect of LED lighting? What is its development trend?

Answer: LED lighting has high luminous efficiency, long life, energy saving and environmental protection, and is easy to realize intelligent control. It is the general trend. Once the price of LED chips is loosened, it will be widely used in the fields of decoration and household lighting.

Q: What are the main factors that determine the working environment temperature of LED street lights?

Answer: The ambient temperature of street lights is mainly determined by the heat generated by the LED itself and the size of the LED shell and the heat dissipation capacity. 78K0/Ix2 is a MCU dedicated to lighting with a temperature resistance of 105℃, so it is more temperature-resistant than general products and more suitable for the lighting industry.

Q: Can we compare DALI and DMX512?

Answer: The transmission speed of DMX is 250kbps and can control 512 nodes, so it is more suitable for simple single-point dimming. The transmission speed of DALI is 1200bps and the transmission distance is 300m. It can control 64 individual nodes and 16 groups, so it is suitable for complex scene dimming modes.

Q: What are the implementation methods of dimming in the 78K0/Ix2 series MCU?

A: You can use the Timer to control the PWM output or turn it off to achieve dimming, or adjust the reference voltage of the comparator or A/D to reduce the current passing through the LED to achieve dimming.

Q: Can the MCU achieve real-time control of high-power RGBLED? How is it achieved in hardware?

A: The implementation control of RGB dimming can be achieved, mainly through independent control of 3-channel LEDs for dimming and color adjustment. In terms of hardware, Ix3 can be used to independently control 3-channel RGBLED lights. The feedback is not color feedback, but current feedback of the RGB LED of each channel. The brightness is controlled by controlling the current to achieve the purpose of color adjustment.

Q: What structure can effectively solve the thermal resistance from LED to atmosphere? Is air cooling, water cooling and oil cooling practical?

A: At present, the heat dissipation of lamps is mainly through metal heat dissipation, and some LEDs are also cooled by air.

Q: What are the simple, reliable and better methods for the heat dissipation design of existing lamps?

A: The heat dissipation of lamps is indeed an important issue. The main thing is to consider the structural heat dissipation when designing lamps, install heat sinks on the power devices on the circuit board, and select devices with good temperature characteristics. Renesas Electronics 78k0/Ix2 series MCU fully considers the environment of lighting applications, with a temperature range of -40℃~105℃.

Q: Is 78K0/Ix2 an MCU specially designed for lighting circuits? Can it be used for other purposes?

A: This series of MCUs is designed for lighting control, focusing on lighting control, but it can also be used in other control fields.

Q: Does 78K0 have LED constant current driver and light intensity sensor?

A: The constant current control of 78K0 is mainly achieved through timer output and comparator feedback. The reversal time point of the LED feedback current detection of the comparator is used to control the timer duty cycle to achieve constant current. This chip does not have a built-in light intensity sensor, and it mainly uses constant current control to make the LED achieve stable light emission.

Q: Is mixed color dimming a multi-channel control? What parameters need to be detected?

Answer: It is multi-channel control. In addition to the necessary constant current control and dimming control, in actual applications, you can also detect the color mixing effect by adding red, green and blue sensors, and add temperature sensors to detect the ambient temperature. Ix2 has multiple 10-bit A/Ds, which can connect multiple sensors.

Q: When you do not dim the light through PWM and use AD to monitor constant current control, how do you understand that PWM is basically constant?

A: PWM adjusts the duty cycle according to the feedback of the comparator, so it is not constant. The current of different LEDs at the same voltage is different. Since the light emission of the LED is determined by the forward current, constant current control is required instead of constant voltage control. Then, in addition to comparator feedback, constant current control can also be achieved through AD detection. AD detection can be implemented to detect and adjust the current, but using AD requires more software processing, but the ripple is smaller.

Q: What is the operating current of the main MCU of the reference DEMO DALI-DMX512 LED? What is the operating voltage?

Answer: The power consumption of MCU at full speed is about 1mA ~ 2mA. Under 5V voltage, if MCU enters STOP mode, the power consumption can be significantly reduced to about a few μA.

Reference address:Next-generation MCU for LED lighting

History of Lighting Development

First, reviewing the development history of lighting technology, the first generation is represented by incandescent lamps, which have the advantages of low price and good low-temperature starting characteristics, but short life and low luminous efficiency. The second generation is represented by fluorescent lamps, which have long life, high luminous efficiency and low cost, but the disadvantages are that they contain heavy metal mercury and the ballast/starter has high power consumption. The third generation is represented by high-pressure gas light sources, which have the advantages of strong penetration and high reflectivity, but contain heavy metal mercury, low color rendering, and need to install a rectifier. LED belongs to the fourth generation of lighting equipment, which has low working voltage, safety and energy saving, low maintenance cost and long life. The main problem at present is high price and high heat generation. It should be pointed out that there is no manufacturer corresponding to the recycling of metal mercury in lamps, but LED does not contain mercury.

Lighting market trend

Lighting accounts for a large proportion of household/commercial electricity consumption, about 17%. Large consumption causes problems such as waste of resources, carbon dioxide emissions and global warming. Therefore, the demand for green and energy-saving lighting systems is gradually increasing worldwide. With the development and improvement of lighting sources, lighting power consumption is gradually reduced, and the power consumption of LED is only 1/8 of that of incandescent lamps. At the same time, the lighting system adopts intelligent lighting control systems with various communications and sensors to improve application efficiency.

Japan launched the "21st Century Lighting" plan in 1998, aiming to increase the energy efficiency of lighting to twice that of traditional fluorescent lamps through LED technology. South Korea, the European Union, and the United States have also proposed their own lighting plans. China has a number of national standards and industry standards related to semiconductor lighting that are about to be issued, and the Ministry of Finance is brewing relevant support policies for semiconductor lighting. The pace of government procurement of semiconductor lighting demonstration projects is accelerating.

Figure 1 Future lighting innovation

Modern LED lighting demand for MCU General

LED lighting market classification can be roughly divided into the following categories: indoor lighting, commercial lighting, automotive lighting, outdoor lighting, traffic signals, entertainment lighting, street lights and electronic display boards, LCD backlights, etc.

With the development of lighting demand and the deepening of energy conservation and emission reduction, future lighting innovation can be carried out from the perspectives of time-sharing control, ambient brightness sensors, motion sensors, heat management, etc.

The future lighting innovation market has great potential, as shown in Figure 1. Time-sharing control means having different brightness in different time periods. Ambient brightness sensors can flexibly respond to the brightness of the environment in which the lamp is located. For example, when it is cloudy, it gets dark earlier than usual, so the street lights will be turned on in advance. Motion sensor detectors mean that if there is no activity around the lamp at night, the brightness will be lowered, and when human activity is detected, the brightness will be increased. In addition, modern lighting requires multiple communication methods. In addition to wireless methods, advanced lighting-specific communication protocols such as DALI or DMX512 make the management of lamps more convenient, and power line carrier communication (PLC) has also attracted much attention in recent years. The

development direction of intelligent lighting

The development direction of intelligent lighting presents several development directions: the integration of MCU is improved, the required peripherals are reduced, and it is more environmentally friendly; LED meets the color mood of family scene dimming and is more humanized; various communication protocols facilitate the expansion of dimming systems and enhance scalability; wireless connection methods enable lighting communication to be integrated into smart homes and achieve integration. The popularization of smart homes can promote green and low-carbon life and protect the environment. Intelligent mixed color dimming requires scene lighting that supports wireless communication. The APPLILET HCD tool can facilitate the development and debugging of mixed color dimming, which is very practical.

Figure 2 Feedback control through comparator

Figure 3 Feedback control through A/D converter

Figure 4 LED constant current control operation flow chart (LED = 3 channels)

Requirements of modern LED lighting

Requirements for LED lighting include both domestic lighting and non-domestic lighting.

Domestic lighting:

(1) Longer working life

(2) Low cost and small size

(3) Low power consumption and high efficiency

(4) Compatible with existing systems

Non-domestic lighting:

(1) Low power consumption and high efficiency

(2) Multi-channel (6 channels or more)

(3) PFC control

(4) PLC communication/wireless communication

The demand for MCU is reflected in the following aspects:

• Accurately control current to extend the life of lamps

• Multiple protection functions to ensure the safety of lamps

• High integration, saving space and cost

• Flexible and precise dimming, less energy consumption for the same brightness.

• Provide independent timer threshold output function for multiple channels at the same time

• Diversified communication methods, support IR/wireless/DALI/ DMX512/ PLC/

• Higher operating temperature (85℃~105℃)

• More practical evaluation scheme

Demands of the lighting market

Combined with high dimming accuracy, low cost, energy saving and emergency protection functions, it is summarized as a single-chip MCU to achieve low-cost and high-performance green energy-saving lighting system.

Application of MCU in LED lighting

In response to the MCU needs of the entire lighting market, Renesas Electronics has launched corresponding MCUs.

78K0/Ix2

In response to these needs of the lighting market, Renesas Electronics' 78K0/Ix2 MCU products have solved these problems well. 78K0/Ix2 has many corresponding features. The PWM output period of 78K0/Ix2 is 25ns, with 16-bit variable frequency timer and internal 40MHz operating clock characteristics, which meets the needs of high-precision dimming. 78K0/Ix2 does not require peripheral ICs, and can be controlled by PFC IC, variable frequency control IC and LED driver IC (LED lighting), effectively reducing costs. The timer high impedance output in the emergency state is linked with the comparator/external interrupt. The corresponding method is to achieve "any brightness" and reduce energy consumption by using sensors/communication, and the communication includes DALI, DMX, remote control and I2C. The lighting ASSP microcontroller 78K0/Ix2 has a variety of memory capacities and pin counts to choose from, corresponding to simple to complex LED lighting applications.

Figure 5 Lighting reference solution

Figure 6 Intelligent DALI-DMX512 LED scene lighting control

Features of the lighting ASSP microcontroller 78K0/Ix2:

•Built-in high-speed crystal oscillator (CPU up to 20MHz)

•High-speed 4-channel 16-bit PWM timer (40MHz)

•Built-in on-chip debugging

•Serial communication (UART, I2C, CSI), built-in DALI (lighting communication) function

•MCU operating temperature can reach 105℃

•Can independently control up to 4 LEDs

•Can adapt to the use environment where LED lighting fixtures generate a lot of heat

•Can easily implement DALI protocol reception/transmission

Features of timers suitable for lighting control:

•Counting clock reaches up to 40MHz

• PWM output with dead time

• Full/half bridge control possible

• 4-channel synchronous output

• Emergency stop function linked to comparator

• LED constant current control possible with A/D converter

• Can be used as a switch signal for LED constant current control or as a dimming brightness control signal

Enhanced analog function:

• Timer synchronized A/D converter

• Built-in 1.2V regulated reference

• 3-channel comparator

• Built-in operational amplifier, including PGA mode (×4/×8/×16/×32), independent mode (using +/ -/ output pins)

• Can be used for fast response feedback operation of LED constant current control

• Can be used to detect tiny signals from sensors to control the brightness of LED lamps

Constant

current control There are two ways of constant current control.

The first is feedback control through comparator. Use comparator to detect LED current and realize constant current control by changing PWM output duty cycle. Independent dimming (28 levels) of each channel can be realized by changing the built-in reference voltage of comparator, as shown in Figure 2.

The second is to perform feedback control through the A/D converter, use the A/D converter to detect the LED current, and achieve constant current control by changing the PWM output duty cycle. Independent dimming of each channel is achieved by changing the target value of the A/D conversion, as shown in Figure 3. The LED

constant current control operation flow chart is shown in Figure 4. As shown in the figure, there are 3 channels of LEDs that need to be controlled, which is a repeated operation of A/D conversion → PWM output fine-tuning. The software operation process is to perform A/D conversion on the feedback resistor voltage of CH1, fine-tune the PWM wave duty cycle input to CH1, and then perform the same operation on channel 2 and channel 3, and repeat the above process. The entire cycle of A/D conversion and detection adjustment of the three channels is about 50μs.

Figure 7 78K0 driverless intelligent dimming LED bulb reference board

Figure 8 78K0/IB2 LED street light solution

Green LED lighting solution The

lighting reference solution of Renesas Electronics consists of 3 parts. Dimming control can be performed through the PC GUI. The PC and communication board are connected through a USB cable. The scene lighting board and the communication board can be realized by infrared, DALI and DMX512. In the lighting reference solution of Renesas Electronics, the AppliletEZ for HCD program automatic generation tool can be used to realize the involvement, compilation and burning of the lighting control program. The lighting reference solution is shown in Figure 5. Advantages

of 78K0/IB2 low-cost high-brightness LED dimming (color adjustment) control:

• 3-channel independent constant current control (high-brightness LED)

• Dimming control, color adjustment control

• Communication mode (DALI, DMX512, AD input)

Intelligent DALI-DMX512 LED scene lighting control is shown in Figure 6. Through the internal reference voltage/PWM duty cycle of the comparator, 3-channel independent LED dimming (28 levels) can be performed; through the synchronous control of the 8-bit PWM TMH1, the dimming accuracy can be further improved.

The 78K0 driverless intelligent dimming LED bulb reference board is shown in Figure 7. Ordinary incandescent lamps have high power consumption and low energy efficiency ratio of dimming. The 78K0 driverless intelligent dimming LED bulb reference board can achieve AC220V without PFC adjustment function; remote control dimming (custom 315M RF); small PCB is easy to integrate.

The LED street light solution based on 78K0/IB2 is shown in Figure 8. It can achieve AC220V with PFC; total driving power is 60W; the dimming communication interface can use RS485/PLC interface.

Development tools

The first step is to generate device drivers through the device driver automatic generation tool (Applilet2). The second step is to edit the program (integrated development environment) (source program management, editing, tool management) through Project Manager (PM+). The third step is debugging (ID78K0) and simulation. Operation confirmation is performed through MINICUBE2 (simple), IECube, etc. In addition, for mass production programming tools, in addition to the tools provided by Renesas Electronics, there are also third-party tools that can be supported. Renesas Electronics provides a lighting reference solution kit so that even if you are new to MCU, you can quickly get started.

Q&A Selection

Q: Can LED lighting achieve real-time brightness adjustment or external light control? How to achieve it?

A: Real-time brightness adjustment can be achieved, and external light control can be achieved by adding a brightness sensor.

Q: In actual operation, what principles should lighting design follow?

A: Lighting design should be people-oriented, but safety and practicality must be considered first, as well as illumination requirements, installation methods, and maintenance methods, and finally combined with humanized creativity. A good lighting design must have the above prerequisites.

Q: Please introduce how to implement the PFC function in the MCU?

A: The current solution uses a boost APFC, which implements PFC through the built-in comparator and PWM function of the MCU, without the need for peripheral IC.

Q: What is the prospect of LED lighting? What is its development trend?

Answer: LED lighting has high luminous efficiency, long life, energy saving and environmental protection, and is easy to realize intelligent control. It is the general trend. Once the price of LED chips is loosened, it will be widely used in the fields of decoration and household lighting.

Q: What are the main factors that determine the working environment temperature of LED street lights?

Answer: The ambient temperature of street lights is mainly determined by the heat generated by the LED itself and the size of the LED shell and the heat dissipation capacity. 78K0/Ix2 is a MCU dedicated to lighting with a temperature resistance of 105℃, so it is more temperature-resistant than general products and more suitable for the lighting industry.

Q: Can we compare DALI and DMX512?

Answer: The transmission speed of DMX is 250kbps and can control 512 nodes, so it is more suitable for simple single-point dimming. The transmission speed of DALI is 1200bps and the transmission distance is 300m. It can control 64 individual nodes and 16 groups, so it is suitable for complex scene dimming modes.

Q: What are the implementation methods of dimming in the 78K0/Ix2 series MCU?

A: You can use the Timer to control the PWM output or turn it off to achieve dimming, or adjust the reference voltage of the comparator or A/D to reduce the current passing through the LED to achieve dimming.

Q: Can the MCU achieve real-time control of high-power RGBLED? How is it achieved in hardware?

A: The implementation control of RGB dimming can be achieved, mainly through independent control of 3-channel LEDs for dimming and color adjustment. In terms of hardware, Ix3 can be used to independently control 3-channel RGBLED lights. The feedback is not color feedback, but current feedback of the RGB LED of each channel. The brightness is controlled by controlling the current to achieve the purpose of color adjustment.

Q: What structure can effectively solve the thermal resistance from LED to atmosphere? Is air cooling, water cooling and oil cooling practical?

A: At present, the heat dissipation of lamps is mainly through metal heat dissipation, and some LEDs are also cooled by air.

Q: What are the simple, reliable and better methods for the heat dissipation design of existing lamps?

A: The heat dissipation of lamps is indeed an important issue. The main thing is to consider the structural heat dissipation when designing lamps, install heat sinks on the power devices on the circuit board, and select devices with good temperature characteristics. Renesas Electronics 78k0/Ix2 series MCU fully considers the environment of lighting applications, with a temperature range of -40℃~105℃.

Q: Is 78K0/Ix2 an MCU specially designed for lighting circuits? Can it be used for other purposes?

A: This series of MCUs is designed for lighting control, focusing on lighting control, but it can also be used in other control fields.

Q: Does 78K0 have LED constant current driver and light intensity sensor?

A: The constant current control of 78K0 is mainly achieved through timer output and comparator feedback. The reversal time point of the LED feedback current detection of the comparator is used to control the timer duty cycle to achieve constant current. This chip does not have a built-in light intensity sensor, and it mainly uses constant current control to make the LED achieve stable light emission.

Q: Is mixed color dimming a multi-channel control? What parameters need to be detected?

Answer: It is multi-channel control. In addition to the necessary constant current control and dimming control, in actual applications, you can also detect the color mixing effect by adding red, green and blue sensors, and add temperature sensors to detect the ambient temperature. Ix2 has multiple 10-bit A/Ds, which can connect multiple sensors.

Q: When you do not dim the light through PWM and use AD to monitor constant current control, how do you understand that PWM is basically constant?

A: PWM adjusts the duty cycle according to the feedback of the comparator, so it is not constant. The current of different LEDs at the same voltage is different. Since the light emission of the LED is determined by the forward current, constant current control is required instead of constant voltage control. Then, in addition to comparator feedback, constant current control can also be achieved through AD detection. AD detection can be implemented to detect and adjust the current, but using AD requires more software processing, but the ripple is smaller.

Q: What is the operating current of the main MCU of the reference DEMO DALI-DMX512 LED? What is the operating voltage?

Answer: The power consumption of MCU at full speed is about 1mA ~ 2mA. Under 5V voltage, if MCU enters STOP mode, the power consumption can be significantly reduced to about a few μA.

Previous article:LED Driver Characteristics Analysis

Next article:PowerintLNK419EG18WT8 Tube Lamp LED Driver Design (DER298)

Recommended ReadingLatest update time:2024-11-16 15:37

LED Lighting Energy-saving Street Lamp Principle Analysis and Design

At present, in the field of high-brightness LED street lamp drivers, the two main technical solutions that are widely used at home and abroad are "using dedicated power supply chips" and "using switching power supplies with discrete components". In order to meet the needs of "intelligence", a single-chip micr

[Power Management]

Latest Power Management Articles

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

MoreSelected Circuit Diagrams

MorePopular Articles

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

MoreDaily News

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

Guess you like

- mpy's LoRa driver library uPyLora

- Can I create a C program with only a hex file?

- [NXP Rapid IoT Review] Unfinished "IKEA Alarm Clock" and Review Summary

- Will you still go crazy shopping on Double 11 now?

- Answer the questions and get a gift | Rochester Electronics will help you solve the problems of the entire semiconductor cycle

- C language (vd6.0) sleep function usage and delay usage

- Battery applications in medical monitoring and the changing environment

- TI Power Supply Learning and Growth Road: DC-DC/AC-DC Control Circuit

- Thank you + thank you EEWORLD

- msp430 library serial PWM

ST Power Management Guide

ST Power Management Guide

京公网安备 11010802033920号

京公网安备 11010802033920号