A microphone is an energy conversion device that converts sound signals into electrical signals. It is a device that is exactly the opposite of a speaker (electric → acoustic). It is the two terminals of a sound device, the microphone is the input, and the speaker is the output. It is also called a microphone core, microphone, microphone, and microphone. This article mainly introduces how to identify the positive and negative poles of a microphone, and how to measure a microphone with a multimeter. First, let's understand the structure of a microphone.

Microphone structure

1. Dustproof net:

It protects the microphone, prevents dust from falling onto the diaphragm, prevents external objects from puncturing the diaphragm, and also has a short-term waterproof effect.

2. Shell

The supporting parts of the entire microphone, with other parts encapsulated in the outer casing, are the grounding point of the microphone and can also play a role in electromagnetic shielding.

3. Diaphragm

It is a main component for sound-to-electricity conversion. It is a stretched Teflon plastic film glued to a thin metal ring. The side of the film that contacts the metal ring is coated with a very thin metal layer. The film can be charged with electric charge and is also an electrode plate of a variable capacitor, and it is a vibrating plate.

4. Gasket:

The distance between the two plates of the supporting capacitor is left with a gap, providing a space for the diaphragm to vibrate, thereby changing the capacitance.

5. Plate:

The other electrode of the capacitor is connected to the G pole of the FET.

6. Polar ring:

Connect the plate to the G pole of the FET and provide support.

7. Cavity:

Fix the plate and the ring to prevent the plate and the ring from short-circuiting to the case (S and G poles of FET are short-circuited).

8. PCB assembly:

It is equipped with devices such as FET and capacitors, and also serves to fix other components.

9. PIN: Some microphones have PIN on the PCB, which can be soldered to other PCBs to connect to the front pole type. The back pole type is also slightly different in structure.

How to identify the positive and negative poles of a microphone

Look at the two tin points on the board. If they are independent, they are the positive pole. If the copper foil is connected to the outer shell, it is the negative pole. Or use a multimeter to measure the conductivity. One of the tin points and the outer shell are connected together.

How to test microphone with multimeter

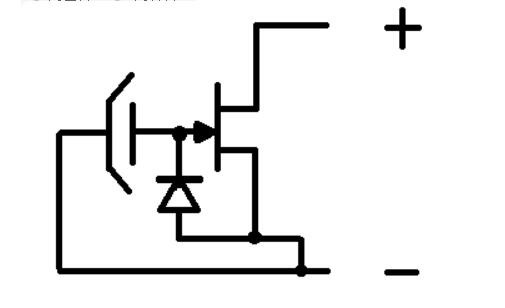

Condenser labels are generally electret type, and the basic structure is shown in the figure below.

1. A normal electret can be tested with a multimeter. The general model directly measures the resistance value around 2K. If you blow or knock on it, you can see a significant change in resistance.

2. If it is a digital multimeter, connect the red test lead to the positive pole of the electret and the black one to the negative pole (usually the leg connected to the shell). The conventional model 2k resistance is good, and the change in blowing and knocking is generally greater than 500 ohms. The greater the change, the better the sensitivity.

3. If you use a pointer multimeter, select the right gear, connect the black test lead to the negative pole of the electret, and the red one to the positive pole. The test method is the same.

The above can only test the sensitivity and the general quality, but cannot determine other parameters, such as distortion and noise.

Previous article:Introduction to the principles of clamp ammeter and current clamp testing current

Next article:Methods and precautions for using two multimeters

- Popular Resources

- Popular amplifiers

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- In what situations are non-contact temperature sensors widely used?

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Download from the Internet--ARM Getting Started Notes

- Learn ARM development(22)

- Learn ARM development(21)

- Learn ARM development(20)

- Learn ARM development(19)

- Learn ARM development(14)

- Learn ARM development(15)

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- Lead Angle/Conduction Angle of Brushless DC Motor

- FIR filter design based on FPGA (source code download attached)

- The timing relationship between voltage and current lead and lag

- NE555 Internal Structure

- PADS Packaging

- MSP430 development and programming environment construction

- "Playing with the board" + Yu Zhennan's STM32 development board experiment 1

- DSP implements external SRAM

- LSM6DSO MicroPython driver porting

- Shenzhen Nengdian Technology Co., Ltd. D1CS-D54 single-point capacitive liquid level sensor test report

AP393S

AP393S

京公网安备 11010802033920号

京公网安备 11010802033920号