1 Introduction

Order analysis is a powerful tool for studying, designing, and verifying rotating or reciprocating systems with time-varying angular velocity. Similar to frequency domain analysis, you can think of order analysis as a signal scalpel that dissects sound, vibration, and other dynamic signals into components related to the physical quantities of the mechanical system. This gives you a better understanding of the system and the ability to identify characteristics that vary with time and operating conditions. Unlike power spectrum or other frequency domain analysis standards, order analysis works even when the signal source is subject to angular velocity variations or frequency/Doppler shifts. The Order Analysis

Order analysis is a powerful tool for studying, designing, and verifying rotating or reciprocating systems with time-varying angular velocity. Similar to frequency domain analysis, you can think of order analysis as a signal scalpel that dissects sound, vibration, and other dynamic signals into components related to the physical quantities of the mechanical system. This gives you a better understanding of the system and the ability to identify characteristics that vary with time and operating conditions. Unlike power spectrum or other frequency domain analysis standards, order analysis works even when the signal source is subject to angular velocity variations or frequency/Doppler shifts. The Order Analysis

VIs included in the Sound and Vibration Measurement Suite provide the ability to calculate, analyze angular velocity, and extract order components from raw noise and vibration signals. Power distribution can be measured as a function of time or angular velocity, while the phase and amplitude of any order component can be measured as a function of angular velocity. Data can be displayed in the form of waterfall plots, trajectory plots, polar plots, and Bode plots.

In addition to the advanced VIs that provide flexibility and enhanced analysis process control, the kit also includes a set of express VIs that allow you to perform simple tasks without much programming. Along with the toolkit are a large number of examples that demonstrate basic order analysis tasks, such as data acquisition, data display, Gabor order tracking, and resampled order tracking for analog and digital tachometer signal processing. With the help of these examples, you can develop application software more quickly.

You can apply order analysis to dynamic signals generated by mechanical systems that contain rotating and reciprocating parts. Order analysis is commonly used in machinery condition monitoring (MCM) and noise, vibration, and harshness (NVH) monitoring. With additional online processing capabilities, you can easily create flexible applications based on condition monitoring and predictive maintenance. NI's NI dynamic signal acquisition devices use 24-bit analog/digital converters and anti-aliasing filters, making them ideal for acquiring sound and vibration signals.

2. Quick VIs for Order Analysis

The Sound and Vibration Measurement Suite provides quick, easy-to-learn, and easy-to-use VIs for the most common applications, including:

- Analog speed signal processing

- Order Power Spectrum Analysis

- Spectral analysis of waterfall and color plots

- Order Tracking - Magnitude and Phase

- Order waveform extraction

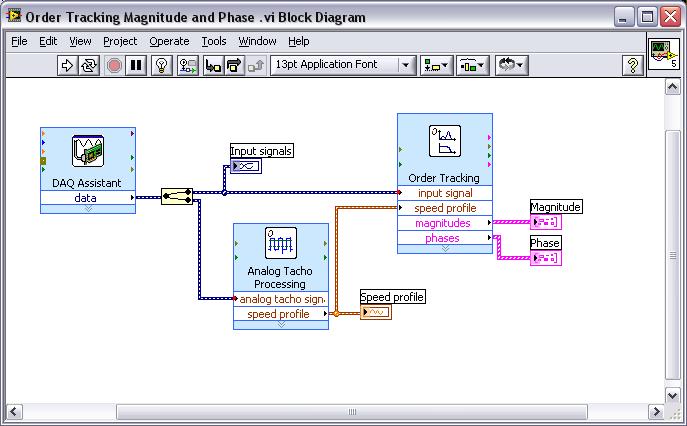

Shown below is an example of an order tracking application with simultaneous magnitude and phase tracking of 4 orders (1x, 2x, 3x and 10x).

3. Order analysis functions and description tables

- Speed processing

- Order Power Spectrum

- Order Tracking

- Order Extraction

- Angle Resampling

- Waterfall Chart

- Track and axle axis diagram

- Polar and Bode plots

- Envelope Detection

|

Measurement items |

Function |

illustrate |

| show |

|

Use the display control VIs and indicators to configure and use the included charts to display acquired data and processing results |

| Envelope analysis | Envelope Detection | Use envelope detection analysis to identify mechanical faults that have an amplitude modulation effect on mechanical vibration signals |

| Order Analysis |

|

Use the Order Analysis VIs to compute order-related results such as order plot, order magnitude and phase, order spectrum, and order waveform. |

| Low speed compensation | Low speed compensation | Use the OAT Get Vector Reference VI to extract the vector reference signal. Use the OAT Get Constant Angle Reference VI to extract the constant angle reference signal from the slow speed vibration and tachometer signals. Use the OAT Compensate Vector Signal VI to remove the slow speed error from the vector signal. Use the OAT Compensate Constant Angle Signal VI to remove the slow speed error from the constant angle signal. [HY1] |

| Speed signal processing | Analog and digital speed signal processing | Use the Speed Signal Processing VIs to process analog and digital speed signals |

Previous article:Vibration Fatigue Analysis Based on LabVIEW

Next article:The software and hardware structure of virtual instrument system

- Popular Resources

- Popular amplifiers

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- In what situations are non-contact temperature sensors widely used?

- How non-contact temperature sensors measure internal temperature

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Why software-defined vehicles transform cars from tools into living spaces

- How Lucid is overtaking Tesla with smaller motors

- Wi-Fi 8 specification is on the way: 2.4/5/6GHz triple-band operation

- Wi-Fi 8 specification is on the way: 2.4/5/6GHz triple-band operation

- Vietnam's chip packaging and testing business is growing, and supply-side fragmentation is splitting the market

- Vietnam's chip packaging and testing business is growing, and supply-side fragmentation is splitting the market

- Three steps to govern hybrid multicloud environments

- Three steps to govern hybrid multicloud environments

- Microchip Accelerates Real-Time Edge AI Deployment with NVIDIA Holoscan Platform

- Microchip Accelerates Real-Time Edge AI Deployment with NVIDIA Holoscan Platform

- CalcToolBox 2 based on micropython

- DIY handheld computer with ESP32 and Raspberry Pi

- How is the 64-bit MAC address of the CC2530 device selected?

- Check and compare the specified current limit with the actual current limit. Have you used counterfeit LM257x and LM259x?

- I'm soldering a board recently, but I saw that the circuit requires 500k ohm and 5meg resistors. Do you have something similar that I can use? ?

- MSP430 Learning Experience

- Understanding and Utilizing Solar Loads for Augmented Reality Head-Up Displays

- For example, for a 24-bit ADC, we only know the accuracy. How is the sampling speed/sampling rate of the microcontroller calculated?

- #Idle Market#Selling Texas Instruments Tiva C Series TM4C123G Development Board

- A Preliminary Study on the Working Principle of PCIe

INA110MD-S

INA110MD-S

京公网安备 11010802033920号

京公网安备 11010802033920号