In the steam flow measurement in industrial production, steam plays a very important role as an important intermediate auxiliary agent and production raw material in production. However, due to the special nature of steam, inaccurate measurement often occurs. How to effectively improve the accuracy of steam flow measurement has always been a goal pursued by people. Instruments and standard orifice plates, vortex flowmeters, elbow flowmeters and other products used to measure steam in production, but the most used are standard orifice flowmeters. This article analyzes the reasons for the low accuracy in steam flow measurement. According to the specific situation of our company's steam flow measurement, and mainly for orifice flowmeters , from the primary throttling element, pressure pipe, to the influence of density compensation and correlation coefficient, methods to improve measurement accuracy are proposed.

1. Error caused by primary measuring element

The throttling element in the orifice flowmeter is a sharp right-angle edge. The fluid shrinks at the inlet of the throttling element. According to the Bernoulli equation, the flow rate increases and the pressure decreases. The measurement principle of the orifice is based on the pressure difference between the inlet and outlet of the orifice. After the orifice is blunted, the outflow coefficient increases, resulting in measurement errors. The influence of the outflow coefficient on steam flow measurement is ubiquitous.

The measuring tube is also a component of the throttling device. Its structural dimensions have an important influence on the flow state of the fluid. In addition to meeting the requirements of 10D in front and 5D in the back, the measuring tube also has requirements for the smoothness of the inner surface. The flow velocity distribution of the rough tube is different from that of the smooth tube, and the outflow coefficient is also different. The scaling and corrosion of the pipeline will change the outflow coefficient and produce measurement errors. For

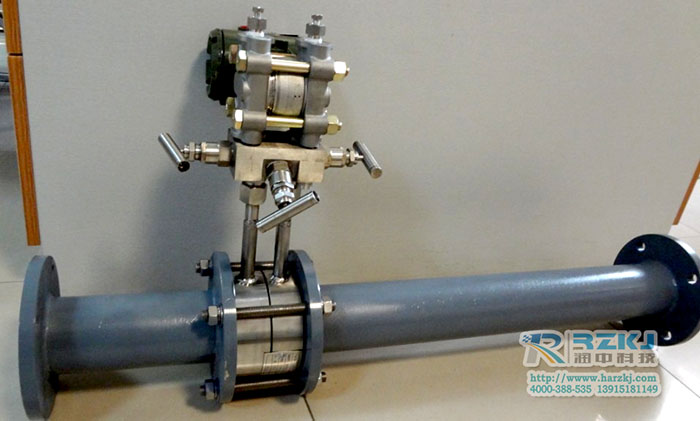

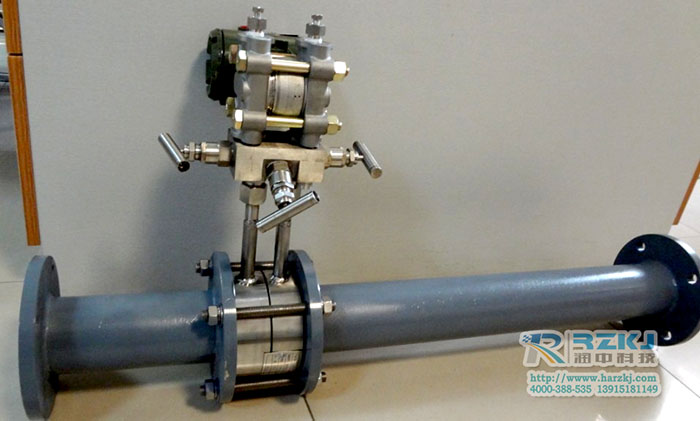

the problem of wear on the edge of the orifice plate inlet, we can use a standard nozzle. Since the nozzle inlet is a smooth curved surface, its wear resistance, anti-fouling and anti-deformation degree are much better than the orifice plate. The stability of the outflow coefficient is also better than that of the orifice plate, and the pressure loss is much smaller than that of the orifice plate. Moreover, its calibration cycle is 4 years, which greatly reduces the maintenance cost.

For the problem of measuring tubes, try to use smooth and high-quality pipes when installing the pipeline. If necessary, ask professional manufacturers to customize measuring pipes, connecting flanges, condensers, etc. The temperature and pressure measurement points for compensation can also be obtained at the same time. Although the one-time investment is higher, it is generally not replaced because there is no special reason after it is put into use. The longer the service cycle, the better, so the comprehensive economic benefits are still higher.

2. Transmission distortion of measurement signal

The transmission of measurement signal is the transmission of differential pressure signal before and after the orifice plate to the differential pressure transmitter through the pressure pipe. Due to the different structures, the orifice flowmeter is not directly installed on the pipeline like the vortex flowmeter, and it needs to transmit the signal. For steam flow measurement, the transmission part can be composed of valves, pressure pipes, condensers and other components. For the signal transmission components, it should be ensured that the transmission signal is not distorted. Most of the faults in actual use are often caused by signal transmission distortion. The transmission distortion generated by the differential pressure signal has a greater impact than the temperature and pressure signal distortion used as compensation, and must be paid attention to. The condenser is in a key position in signal transmission. The liquid level in the condenser is maintained at a certain height, and the excess condensate must be returned to the steam pipeline. It is necessary to ensure that the steam in the condenser is well condensed and the condensate reflux is unobstructed.

The primary root valve of the gas phase pressure pipe should ensure that the steam gas phase enters the condenser, and the excess condensate in the condenser is returned to the steam pipeline. Otherwise, the liquid levels of the two condensers cannot be kept level, which will cause additional errors in the differential pressure signal. For the primary root valve, try to use a gate valve to ensure that the pressure signal is transmitted smoothly and without obstruction, reducing the measurement error.

The pressure pipe used for measurement should be insulated and heated, otherwise it will not work normally in winter. Regardless of whether electric heating or steam heating is used, it is necessary to ensure that the two pressure pipes are heated equally, otherwise additional differential pressure errors will be generated due to the different densities of the liquid in the pressure pipes.

The transmitter used for pressure compensation is generally not at the same height as the pressure port. If the transmitter is lower than the pressure port, the measured pressure is the pressure of the steam in the pipeline plus the pressure generated by the condensate in the pressure pipe. This part of the pressure can be migrated in the transmitter. Make the pressure measured by the transmitter the actual steam pressure in the pipeline.

3. Errors caused by steam density problems

When measuring steam mass flow, it is necessary to calculate according to the density of steam. Measurement errors are generated due to inaccurate calculation of steam density. The vortex flowmeter in our company's steam flow measurement instrument uses the steam density value provided by the process workshop as a reference value, not the actual density value, and the resulting steam flow will have errors with the actual flow. When choosing a vortex flowmeter, it is best to choose a model that can perform temperature and pressure compensation, and install temperature and pressure measuring elements to obtain temperature and pressure values. When our company uses an orifice flowmeter as a steam flowmeter , the measured flow is displayed by the DCS system without temperature and pressure compensation. In order to improve the accuracy of the measurement, temperature and pressure compensation must be performed. For the orifice flowmeter, when obtaining the differential pressure signal, the temperature and pressure signals must also be measured, and temperature and pressure compensation is performed through the dedicated software in the DCS.

4. The influence of the correlation coefficient

The outflow coefficient C and the expansion coefficient ε can be regarded as constants within a certain range. However, when the steam condition deviates from the design state, its outflow coefficient C and the expansion coefficient ε will change and cannot be regarded as constants. When measuring small flow, as the Reynolds number decreases, the outflow coefficient C will have a large change. When measuring high pressure, the influence of the gas expansion coefficient ε must be considered. If we only compensate for the influence of density changes, even if the density is fully compensated, the maximum error after the accumulation of other parameter changes is still about 6%, among which the error introduced by the expansion coefficient ε is the largest. Therefore, in order to improve the measurement accuracy of the instrument, in addition to compensating for density, the compensation of other parameter changes in the entire compensation equation should also be considered. The steam measurement module in the DCS not only has density compensation methods, but also correction methods for the outflow coefficient C and the expansion coefficient ε. As long as we choose a suitable flow measurement module, we can improve the measurement accuracy of the steam flow.

It is generally believed that when the steam dryness X is high (X≥95%), the fluid can be regarded as a single-phase fluid. Temperature and pressure compensation can be performed in the usual way. But there is a certain error. The lower the dryness, the greater the density. When the steam dryness is low (X<95%), the fluid in the pipeline is in a two-phase flow state. In severe cases, the fluid flows in layers, resulting in greater errors. At present, there is no online dryness measurement instrument to measure the dryness of steam. The best way is to strengthen the insulation of the steam transmission pipeline, increase the superheat of the steam, make the steam dryness higher, and the measurement is more accurate.

V. Conclusion

Since the flow meter currently used to measure steam has inaccurate measurements due to the particularity of the measured medium, we can only improve the accuracy of steam flow measurement by carefully analyzing the possible causes of errors, from the installation of primary detection elements to the installation of valves, pressure pipes, condensers and differential pressure transmitters, and then taking appropriate measures to prevent possible problems in the temperature and pressure compensation of steam density and the correction of related parameters. Find a successful way to measure steam flow

Reference address:Accuracy Analysis of Steam Flow Measurement Using Orifice Flowmeter

1. Error caused by primary measuring element

The throttling element in the orifice flowmeter is a sharp right-angle edge. The fluid shrinks at the inlet of the throttling element. According to the Bernoulli equation, the flow rate increases and the pressure decreases. The measurement principle of the orifice is based on the pressure difference between the inlet and outlet of the orifice. After the orifice is blunted, the outflow coefficient increases, resulting in measurement errors. The influence of the outflow coefficient on steam flow measurement is ubiquitous.

The measuring tube is also a component of the throttling device. Its structural dimensions have an important influence on the flow state of the fluid. In addition to meeting the requirements of 10D in front and 5D in the back, the measuring tube also has requirements for the smoothness of the inner surface. The flow velocity distribution of the rough tube is different from that of the smooth tube, and the outflow coefficient is also different. The scaling and corrosion of the pipeline will change the outflow coefficient and produce measurement errors. For

the problem of wear on the edge of the orifice plate inlet, we can use a standard nozzle. Since the nozzle inlet is a smooth curved surface, its wear resistance, anti-fouling and anti-deformation degree are much better than the orifice plate. The stability of the outflow coefficient is also better than that of the orifice plate, and the pressure loss is much smaller than that of the orifice plate. Moreover, its calibration cycle is 4 years, which greatly reduces the maintenance cost.

For the problem of measuring tubes, try to use smooth and high-quality pipes when installing the pipeline. If necessary, ask professional manufacturers to customize measuring pipes, connecting flanges, condensers, etc. The temperature and pressure measurement points for compensation can also be obtained at the same time. Although the one-time investment is higher, it is generally not replaced because there is no special reason after it is put into use. The longer the service cycle, the better, so the comprehensive economic benefits are still higher.

2. Transmission distortion of measurement signal

The transmission of measurement signal is the transmission of differential pressure signal before and after the orifice plate to the differential pressure transmitter through the pressure pipe. Due to the different structures, the orifice flowmeter is not directly installed on the pipeline like the vortex flowmeter, and it needs to transmit the signal. For steam flow measurement, the transmission part can be composed of valves, pressure pipes, condensers and other components. For the signal transmission components, it should be ensured that the transmission signal is not distorted. Most of the faults in actual use are often caused by signal transmission distortion. The transmission distortion generated by the differential pressure signal has a greater impact than the temperature and pressure signal distortion used as compensation, and must be paid attention to. The condenser is in a key position in signal transmission. The liquid level in the condenser is maintained at a certain height, and the excess condensate must be returned to the steam pipeline. It is necessary to ensure that the steam in the condenser is well condensed and the condensate reflux is unobstructed.

The primary root valve of the gas phase pressure pipe should ensure that the steam gas phase enters the condenser, and the excess condensate in the condenser is returned to the steam pipeline. Otherwise, the liquid levels of the two condensers cannot be kept level, which will cause additional errors in the differential pressure signal. For the primary root valve, try to use a gate valve to ensure that the pressure signal is transmitted smoothly and without obstruction, reducing the measurement error.

The pressure pipe used for measurement should be insulated and heated, otherwise it will not work normally in winter. Regardless of whether electric heating or steam heating is used, it is necessary to ensure that the two pressure pipes are heated equally, otherwise additional differential pressure errors will be generated due to the different densities of the liquid in the pressure pipes.

The transmitter used for pressure compensation is generally not at the same height as the pressure port. If the transmitter is lower than the pressure port, the measured pressure is the pressure of the steam in the pipeline plus the pressure generated by the condensate in the pressure pipe. This part of the pressure can be migrated in the transmitter. Make the pressure measured by the transmitter the actual steam pressure in the pipeline.

3. Errors caused by steam density problems

When measuring steam mass flow, it is necessary to calculate according to the density of steam. Measurement errors are generated due to inaccurate calculation of steam density. The vortex flowmeter in our company's steam flow measurement instrument uses the steam density value provided by the process workshop as a reference value, not the actual density value, and the resulting steam flow will have errors with the actual flow. When choosing a vortex flowmeter, it is best to choose a model that can perform temperature and pressure compensation, and install temperature and pressure measuring elements to obtain temperature and pressure values. When our company uses an orifice flowmeter as a steam flowmeter , the measured flow is displayed by the DCS system without temperature and pressure compensation. In order to improve the accuracy of the measurement, temperature and pressure compensation must be performed. For the orifice flowmeter, when obtaining the differential pressure signal, the temperature and pressure signals must also be measured, and temperature and pressure compensation is performed through the dedicated software in the DCS.

4. The influence of the correlation coefficient

The outflow coefficient C and the expansion coefficient ε can be regarded as constants within a certain range. However, when the steam condition deviates from the design state, its outflow coefficient C and the expansion coefficient ε will change and cannot be regarded as constants. When measuring small flow, as the Reynolds number decreases, the outflow coefficient C will have a large change. When measuring high pressure, the influence of the gas expansion coefficient ε must be considered. If we only compensate for the influence of density changes, even if the density is fully compensated, the maximum error after the accumulation of other parameter changes is still about 6%, among which the error introduced by the expansion coefficient ε is the largest. Therefore, in order to improve the measurement accuracy of the instrument, in addition to compensating for density, the compensation of other parameter changes in the entire compensation equation should also be considered. The steam measurement module in the DCS not only has density compensation methods, but also correction methods for the outflow coefficient C and the expansion coefficient ε. As long as we choose a suitable flow measurement module, we can improve the measurement accuracy of the steam flow.

It is generally believed that when the steam dryness X is high (X≥95%), the fluid can be regarded as a single-phase fluid. Temperature and pressure compensation can be performed in the usual way. But there is a certain error. The lower the dryness, the greater the density. When the steam dryness is low (X<95%), the fluid in the pipeline is in a two-phase flow state. In severe cases, the fluid flows in layers, resulting in greater errors. At present, there is no online dryness measurement instrument to measure the dryness of steam. The best way is to strengthen the insulation of the steam transmission pipeline, increase the superheat of the steam, make the steam dryness higher, and the measurement is more accurate.

V. Conclusion

Since the flow meter currently used to measure steam has inaccurate measurements due to the particularity of the measured medium, we can only improve the accuracy of steam flow measurement by carefully analyzing the possible causes of errors, from the installation of primary detection elements to the installation of valves, pressure pipes, condensers and differential pressure transmitters, and then taking appropriate measures to prevent possible problems in the temperature and pressure compensation of steam density and the correction of related parameters. Find a successful way to measure steam flow

Previous article:How to correctly understand the cause of the "random magnetism" phenomenon in magnetic float level gauges

Next article:Advantages of radar level meter upgrade system compared with traditional measurement methods

- Popular Resources

- Popular amplifiers

Recommended Content

Latest Test Measurement Articles

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

MoreSelected Circuit Diagrams

MorePopular Articles

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

MoreDaily News

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

Guess you like

- Does it cost a lot to buy an on-load tapchanger tester?

- Requires 3-way hardware SPI

- Matter and Wi-Fi 6: An ideal combination

- Creativity + Focus | ADI Model of “Garage Innovation”

- Proteus MSP430 MCU simulation example 2-color light control

- 【XMC4800 Relax EtherCAT Kit Review】+ Getting started with DAVE, simple application of ADC module

- Today's Live Broadcast | Cytech: Hidden Costs of Isolation System Design

- MSP430F5529 generates PWM waves with CCS

- FPGA Multiplier

- Quartus2 simulation can not produce waveform

Signal Integrity and Power Integrity Analysis (Eric Bogatin)

Signal Integrity and Power Integrity Analysis (Eric Bogatin)

京公网安备 11010802033920号

京公网安备 11010802033920号