TDMS (Technical Data

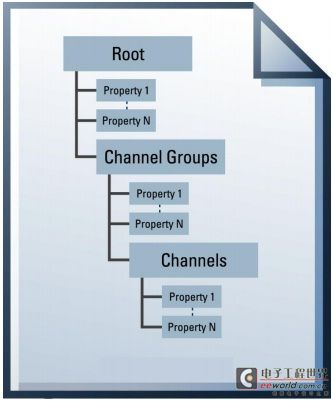

The logical structure of TDMS is divided into three layers: file, channel group, and channel, as shown in Figure 25. Specific properties can be attached to each layer. Programmers can use these three logical layers to define test data very conveniently, and can also retrieve data at any logical layer, which makes data retrieval orderly and convenient to access. http://zone.ni.com/devzone/cda/tut/p/id/5696 .

Figure 25 TDMS function palette

After writing the TDMS file, LabVIEW will automatically generate two files: *.tdms file and *.tdms_index file. The former is the data file (or master file), and the latter is the index file (or header file). The biggest difference between the two is that the index file does not contain raw data

LabVIEW 2009 further improves the support for the TDMS format, upgrading from version 1.0 to version 2.0, and improves the support for high-speed streaming applications and DAQmx application support, which is at least 4 times faster than the previous version of TDMS files. Of course, TDMS also has some disadvantages. For example, the speed is not as fast as the win32 streaming API, it does not support deleting a channel or channel group, and it only supports Windows operating system and real-time platforms such as VxWorks and Phar Lap. In general, the TDMS file format takes into account multiple factors such as speed, logical organization, and ease of use, and is a very good choice for data storage.

Keywords:LabVIEW

Reference address:LabVIEW Data Logging and Storage (V)—TDMS Files

The logical structure of TDMS is divided into three layers: file, channel group, and channel, as shown in Figure 25. Specific properties can be attached to each layer. Programmers can use these three logical layers to define test data very conveniently, and can also retrieve data at any logical layer, which makes data retrieval orderly and convenient to access. http://zone.ni.com/devzone/cda/tut/p/id/5696 .

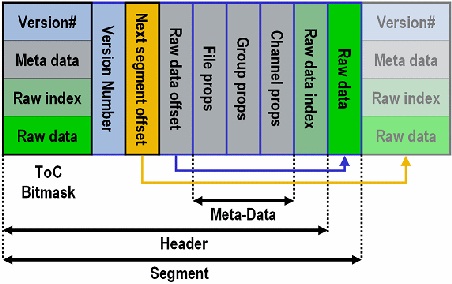

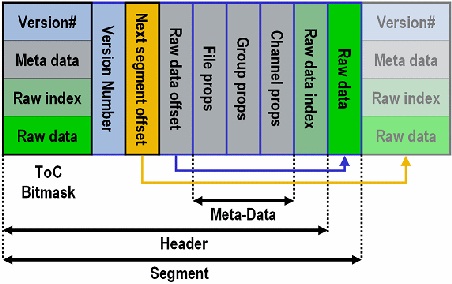

- ToC Bitmask: This is a 32-bit integer data segment, which indicates whether the segment contains meta data

or raw data. - Version number: Indicates the version of the segment, which ensures compatibility with some older TDMS file versions.

- Next segment offset: indicates the offset byte of the next segment.

- Raw

data offset: indicates the offset byte of Raw data. - Meta

Data: Three levels of attribute storage fields. - Raw

data: The actual raw data storage field.

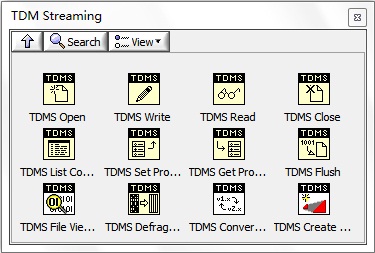

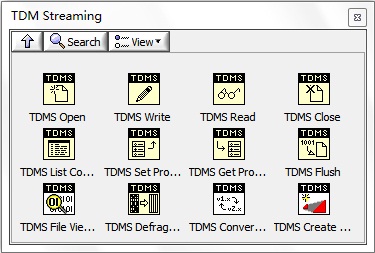

- TDMS Open/Write/Read/Close: Similar to the functions of text files and binary files, programmers only need to remember the three-level logical structure of TDMS files.

- TDMS List Contents: Lists the names of the Groups and Channels in the TDMS file, or lists the names of the Channels contained in the specified Group.

- TDMS Set Properties: Set the properties of a TDMS file, channel group, or channel.

- TDMS Get Properties: Gets the properties of a TDMS file, channel group, or channel.

- TDMS Flush: Refreshes the data of all TDMS files in memory, that is, immediately writes all TDMS data to the hard disk (creates new segments).

- TDMS Defragment: Defragments the storage in the TDMS file. When the TDMS file is large, this function can improve the performance of data access.

- TDMS Create Scaling Information: Creates scaling information for data in TDMS. When the collected raw data needs to use linear, polynomial, or various sensor conversion relationships such as y=ax+b, this function can be used to directly change the data values of certain channels in the TDMS file (the change is irreversible and the scaling information cannot be deleted).

- TDMS File Viewer: This VI can list the properties and data in a TDMS file in a tree format, making it easy for users to view.

Figure 25 TDMS function palette

After writing the TDMS file, LabVIEW will automatically generate two files: *.tdms file and *.tdms_index file. The former is the data file (or master file), and the latter is the index file (or header file). The biggest difference between the two is that the index file does not contain raw data

LabVIEW 2009 further improves the support for the TDMS format, upgrading from version 1.0 to version 2.0, and improves the support for high-speed streaming applications and DAQmx application support, which is at least 4 times faster than the previous version of TDMS files. Of course, TDMS also has some disadvantages. For example, the speed is not as fast as the win32 streaming API, it does not support deleting a channel or channel group, and it only supports Windows operating system and real-time platforms such as VxWorks and Phar Lap. In general, the TDMS file format takes into account multiple factors such as speed, logical organization, and ease of use, and is a very good choice for data storage.

Previous article:Reading and Writing UTF-8 Encoded Text Files in LabVIEW

Next article:LabVIEW Data Logging and Storage (IV)—XML Files

Recommended ReadingLatest update time:2024-11-15 10:16

Design and implementation of wireless automatic measurement and control system based on LabVIEW

In order to solve the problem of difficult explosion pressure measurement at the ammunition explosion site, a wireless automatic measurement and control system was designed using LabVIEW as a tool. It mainly consists of three parts: sensor network nodes, wireless relay station AP and host computer. The measurement and

[Test Measurement]

CNC machine tool network measurement and control system based on LabVIEW--Research on key network communication technologies 2

4.2.3 Shared variable method

Shared variables are another big step taken by LabVIEW to simplify network programming. Through shared variables, users can easily share data between different computers without programming. Users can easily exchange data without understanding any underlying complex network communications.

[Test Measurement]

Common Errors in LabVIEW Code

When you find a problem with a program and then go back to debug, it will inevitably take a lot of time to find the program error. To improve development efficiency, it is best to avoid some common low-level errors when writing code, which can save a lot of debugging time.

Some programming errors are almost encounter

[Test Measurement]

Common shortcut keys in LabVIEW

Ctrl+N: Open VI

Ctrl+E: Switch between front panel and block diagram

Ctrl+/: Maximize the window

Ctrl+T: Distribute the front panel and block diagram up and down/left and right

Ctrl+H: Show context help

Ctrl+B: Clear broken lines

Ctrl+I: Open VI properties

Ctrl+R: Run VI

Ctrl+>: Stop running VI

Ctrl+Shift+Spac

[Test Measurement]

Interactive Application of Arduino and LabVIEW

This article will introduce how to use the proteus simulation environment to realize serial communication between Arduino UNO and LabVIEW. LabVIEW controls the LED light of Arduino UNO through the RS-232 serial port to turn the LED light on and off.

1. Arduino UNO

In the proteus simulation environment, the ATmega328

[Test Measurement]

How should I start learning LabVIEW?

Step 1: First read NI's introductory materials to understand the concept of virtual instruments, the application areas of LabVIEW, programming features, etc.

Step 2: Follow the instructions in LabVIEW Getting Started. (Click New to LabVIEW Getting Started with LabVIEW on the right side of the LabVIEW start scree

[Test Measurement]

Labview implements pulse wave modulation (PAM)

Pulse Amplitude Modulation

Generate a sine signal and get its amplitude input to the amplitude of a square wave signal

This is equivalent to multiplying a square wave signal and a sine signal

By observing its frequency, the resulting PAM signal can be found to have many more peaks than the original cosine signal

Us

[Test Measurement]

Design of Temperature Relay Test System Based on LabVIEW

The temperature relay is a temperature-sensitive component, and its output state is completely determined by the required control temperature. The key process of the temperature relay is the detection of temperature characteristics (operating temperature when heating and recovery temperature when cooling). At present,

[Test Measurement]

- Popular Resources

- Popular amplifiers

-

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang)

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang) -

Arduino Nano collects temperature and humidity data through LabVIEW and DHT11

Arduino Nano collects temperature and humidity data through LabVIEW and DHT11 -

Monocular semantic map localization for autonomous vehicles

Monocular semantic map localization for autonomous vehicles -

Modern Testing Technology and System Integration (Liu Junhua)

Modern Testing Technology and System Integration (Liu Junhua)

Recommended Content

Latest Test Measurement Articles

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- In what situations are non-contact temperature sensors widely used?

- How non-contact temperature sensors measure internal temperature

MoreSelected Circuit Diagrams

MorePopular Articles

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

MoreDaily News

- Detailed explanation of intelligent car body perception system

- How to solve the problem that the servo drive is not enabled

- Why does the servo drive not power on?

- What point should I connect to when the servo is turned on?

- How to turn on the internal enable of Panasonic servo drive?

- What is the rigidity setting of Panasonic servo drive?

- How to change the inertia ratio of Panasonic servo drive

- What is the inertia ratio of the servo motor?

- Is it better for the motor to have a large or small moment of inertia?

- What is the difference between low inertia and high inertia of servo motors?

Guess you like

- [GD32L233C-START Review] Part 2 Compilation, Software Development Environment Review

- Please recommend, is there any domestic dual-channel H-bridge that can drive motors with an operating voltage of 12V or above?

- How to install and use pressure transmitter

- The flashing prompt cannot recognize the device. What's going on?

- Model-Based Design and Its Embedded Implementation

- Q&A on Connectivity: Why Wi-Fi 6 Could Be Your Competitive Advantage

- Why do we need to learn transistor circuits when we already have integrated circuits?

- 2. Hardware Introduction and Development Environment Installation

- 【New Year's Festival Competition】+ Watching Lanterns on the Lantern Festival (multiple photos)

- 5G small base stations are under the spotlight: now is the eve of the outbreak

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang)

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang) Arduino Nano collects temperature and humidity data through LabVIEW and DHT11

Arduino Nano collects temperature and humidity data through LabVIEW and DHT11

京公网安备 11010802033920号

京公网安备 11010802033920号