Over the past 20 years, data acquisition has evolved from a technology with limited applications to a platform that can be applied to a variety of high-performance measurement applications. Through software-centric graphical programming and PC-based modular hardware, engineers and scientists can quickly develop powerful, flexible and highly customizable data acquisition (DAQ) systems.

The ability to easily integrate USB and Wi-Fi in applications provides a new way for DAQ technology to develop. For example, SAPHIR, an NI Alliance Partner in France, recently developed an advanced USB-based sound and vibration monitoring system to help its customers in the construction industry implement structural monitoring to comply with noise regulations in neighboring neighborhoods. They recently expanded their system with Wi-Fi DAQ.

"We used the NI WLS-9163 enclosure with the NI 9234 module to extend the range of our monitoring station to 100 meters. The system provides IEEE 802.11g (Wi-Fi) wireless connectivity for maximum flexibility. The wireless architecture provides a more cost-effective way to expand the system."

From environmental monitoring to mountain bike testing, USB and Wi-Fi DAQ are gaining traction. So how have these DAQ technologies evolved, and what do you need to consider when implementing them?

DAQ often involves multitasking, such as analog I/O, digital I/O, and counter/timers running simultaneously. To achieve these functions, DAQ devices must be able to support multiple data streams simultaneously and quickly read or write data to PC memory. Currently, PCI is the most widely used data acquisition bus and is still used for the highest performance applications. PCI is an ideal choice for DAQ, providing high bandwidth, low latency, bus control, and direct memory access (DMA) channels that allow data streams to be transferred directly to memory. In addition, with the advent of PCI Express, dedicated channels in today's ultra-high-speed and high-channel-count data transfer applications can now reach 1GB/s per slot in one direction. However, when portability and ease of deployment are more important than high transfer speeds, many engineers turn to USB and Wi-Fi.

USB simplifies the task of adding DAQ capabilities to a desktop or laptop computer. With more than two billion USB ports in use worldwide, this versatility makes USB the most straightforward choice. Engineers and scientists can now share devices quickly with USB DAQ, and the system becomes more portable and compact.

USB also presents its own challenges in measurement applications. For example, the theoretical bandwidth of 60 MB/s of high-speed USB is sufficient for most DAQ applications; however, there are several obstacles to overcome in designing USB DAQ hardware and software to achieve this theoretical bandwidth. USB is a host-driven serial port protocol, which means that the operating system must initiate all data transfer requests. This asynchronous data transfer method reduces determinism and increases the burden on the CPU. One way to solve this problem is to buffer the data in additional memory on the device. This will help overcome data loss, but it increases latency and device cost. What is really needed is a way to support multi-DAQ data transfer over USB. In many devices, this idea is limited by the traditional on-board system architecture.

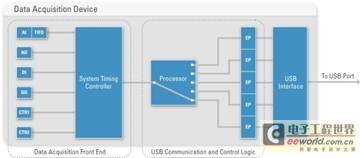

One limiting factor is the processor that connects the DAQ device to the USB port. In standard USB systems, this is typically a single-threaded, instruction-based chip that acts like a switch, bottlenecking the data and allowing only a portion of the data stream to flow at a time. To reduce latency and increase throughput, the host must be able to continuously send data requests to the device. To meet this requirement, the device must make the data ready on the USB port as quickly as possible. The traditional 'single-wire' architecture cannot do this, but the new NI USB signal streaming technology can solve this problem.

Figure 1. DAQ device transmission architecture using standard USB

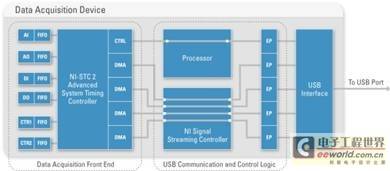

Figure 2. DAQ device transmission architecture using NI Signal Streaming over USB.

As a patent of NI, USB signal streaming technology avoids the switch-like behavior based on the processor through a multithreaded approach. In conjunction with the NI-STC 2 system timing controller, the NI signal streaming controller provides 4 high-speed DMA channels to support direct data transfer to 4 USB ports. This method saves the occupation of processor resources. At this time, the processor can accept high-level instructions from the host and convert them into a series of register-level instructions acceptable to the DAQ device. This can minimize the number of instructions from the host and reduce latency.

Signal Streaming improves single-ended acquisition performance for analog input and output by 1600% and 250% respectively. This means that multiple bidirectional data streams can be run simultaneously, and NI DAQ devices can reach speeds of more than 26MB/s.

Despite these advances, USB cables are still limited to 5 meters. This length is limited by the 26ns delay standard. Since USB uses source and voltage mode drivers, this delay is necessary to prevent signal reflections. The 5 meter cable is a practical maximum. Assuming the worst-case delay, a full-speed device connected to a 5 meter hub or USB cable will experience 280ps of latency. Reducing this value to 0ps would only increase the USB cable length by 0.05 meters. This means that USB is not practical for applications such as distributed environmental monitoring. [page]

To extend the distance that a measurement system can be used, the traditional solution is to use a cabled industrial network, which increases both cost and complexity. As a result, there is growing interest in wireless networks as an alternative. The challenge now is to use new technologies while maintaining the ease of configuration of USB. This is not only related to the design of new applications, but also the expansion of many existing applications may use wireless. The vibration monitoring system of SAPHIR mentioned above originally used USB, but the increase in costs caused them to switch to Wi-Fi because a laptop was required at each test location. This conversion must be fast, simple and economical.

Wireless sensor networks have been used for many years, but their applications require custom hardware and proprietary software. This makes the construction of simple applications complex and requires extremely high costs and engineering skills. In addition, many existing wireless sensor technologies are associated with single-point measurements, and there is little data stream waveform acquisition. The ideal wireless DAQ solution should provide high performance, ease of use, reliability, and security. Based on the above, NI chose IEEE 802.11b/g, with 128-bit AES encryption and IEEE 802.11i (WPA2) support. The widespread use of IEEE 802.11 and its transmission speed of up to 56 MB/s provide ease of use and sufficient performance to support 100kS/s data stream acquisition.

IEEE 802.11 is also reliable enough. The IEEE 802.11 standard specifies the air interface protocol between wireless clients and between wireless clients and base stations or access points. The standard also specifies the physical layer (PHY) and the media access control layer (MAC), and specifically solves the compatibility issues between manufacturers and wireless devices. Connecting wireless DAQ devices that do not comply with the IEEE standard often requires a lot of effort and makes the test unreliable. So, what is the IEEE 802.11 standard and why is it necessary for DAQ?

The basic connection mechanism of IEEE 802.11 is the Carrier Sense Multiple Access with Collision Detection (CSMA/CA) protocol, similar to Ethernet. Any device that wants to transmit data first listens to the physical network; if the network is busy (for example, another device is transmitting), it delays and retransmits at a later time. If the network is idle for a predetermined period of time (DIFS – Distributed Frame Interval), the transmission begins. But problems arise when two devices find the network idle at the same time. Both devices start transmitting, causing a collision.

In a wired system such as Ethernet, such collisions are easily detected and counted because all devices can "hear" each other. In a wireless network, a device may perceive the network as idle, when in fact the intended receiver (centrally located) may be busy receiving data from another device that is out of range. In normal operation, the receiver adds a checksum to the message and sends an acknowledgment (ACK) back to the device. If the device does not receive an acknowledgment, it will continue to try to send requests even if the detected network is still idle.

This data protection protocol is a must in DAQ applications, unlike wireless music or video streaming, any data loss will cause abnormal results and invalidate the measurement results. IEEE 802.11 standard wireless products are considered reliable and flexible, but there is no mention of security in the 400-page standard document.

Many applications require security in data transmission—for reasons of national security or to hide data from potential competitors. The language of wireless security can be complex and involve even more acronyms. All security is based on a combination of various data encodings and user permissions. There are several encoding standards. First came WEP (Wired Equivalent Privacy), followed by WPA (Wi-Fi Protected Access), but both have the potential to compromise security. The latest Wi-Fi products comply with the WPA2 standard and use AES (Advanced Encryption Standard). It uses a 128-bit cipher, which is much harder to crack than the algorithms used in WEP and WPA. In fact, the National Institute of Standards and Technology (NIST) selected AES as the encryption standard used by all U.S. government agencies. WPA2 has proven to be robust and secure and can be used in a variety of applications, including Wi-Fi DAQ.

SAPHIR chose to use NI's WLS-9163 Wi-Fi box because it complies with the IEEE 802.11 protocol and WPA2 security. They use the same NI-DAQmx driver as the previous USB system, which allows them to upgrade to Wi-Fi without rewriting code. Both the USB and Wi-Fi boxes use the same C Series platform as the acquisition and signal conditioning modules, thus minimizing hardware cost expenditures. This also simplifies and accelerates the transition to a more practical and powerful Wi-Fi system.

Figure 3. The WLS-9163 includes the NI-9234 dynamic signal acquisition module.

Wi-Fi is now available as a simple and secure DAQ option for scientists and engineers in any industry. It has successfully enabled dynamic data transfer in applications where wired solutions would be impractical, impossible or too costly. Today's scientists and engineers do not have to worry about the limitations imposed by the bus. Instead, through flexible software and easy-to-use drivers, developers can specify the bus that suits the application, from the high throughput of PCI Express to the simple plug-and-play configuration of USB, or the high flexibility and mobility of Wi-Fi. Now, domain experts have the power to choose a DAQ system that better meets their needs.

Previous article:Measuring the linearity of differential-output, current-mode digital-to-analog converters (DACs)

Next article:Analog-to-Digital Converter Clock Optimization: A Test Engineering Perspective

Recommended ReadingLatest update time:2024-11-16 13:40

- Popular Resources

- Popular amplifiers

-

Siemens Motion Control Technology and Engineering Applications (Tongxue, edited by Wu Xiaojun)

Siemens Motion Control Technology and Engineering Applications (Tongxue, edited by Wu Xiaojun) -

Virtualization Technology Practice Guide - High-efficiency and low-cost solutions for small and medium-sized enterprises (Wang Chunhai)

Virtualization Technology Practice Guide - High-efficiency and low-cost solutions for small and medium-sized enterprises (Wang Chunhai) -

2024 DigiKey Innovation Contest

2024 DigiKey Innovation Contest -

MCU C language programming and Proteus simulation technology (Xu Aijun)

MCU C language programming and Proteus simulation technology (Xu Aijun)

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- [RVB2601 Creative Application Development] Build CDK Development Environment

- This strange cut made the PCB hang inexplicably

- It seems that I have a good relationship with Shide——Part 2

- 【Silicon Labs BG22-EK4108A Bluetooth Development Review】I. Hardware Appreciation and Development Environment Introduction

- [ESP32-S2-Kaluga-1 Review] 4. LCD example compilation pitfalls

- HuaDa MCU FLASH operation instructions and precautions

- I am working on a product for traffic security equipment recently. The project has high safety requirements and heavy tasks. I am having a headache recently...

- Several issues on key-controlled 8X8LED dot matrix screen displaying graphics program

- FAQ: PolarFire SoC FPGA Secure Boot | Microchip Security Solutions Seminar Series 12

- Some Problems on Measuring AC Current with Current Transformer

Siemens Motion Control Technology and Engineering Applications (Tongxue, edited by Wu Xiaojun)

Siemens Motion Control Technology and Engineering Applications (Tongxue, edited by Wu Xiaojun) 2024 DigiKey Innovation Contest

2024 DigiKey Innovation Contest

京公网安备 11010802033920号

京公网安备 11010802033920号