Ultrasonic flowmeters derive gas volume flow rate by measuring the propagation time of ultrasonic pulses in the fluid. For an ultrasonic flowmeter, the accuracy of the flow rate is determined as a function of the flowmeter design and calculation method, as well as the upstream piping requirements, which is different from many traditional measurement methods.

For example, orifice flowmeters measure flow and require symmetrical, vortex-free flow within the accuracy of a determined discharge coefficient. In order to obtain the published flow measurement performance, AGA Report No. 3 recommends minimum straight pipe length, pipe diameter changes, and installation requirements upstream of the orifice flowmeter. As the orifice flowmeter size (beta ratio) increases, the orifice plate's shaping effect on the velocity profile is reduced due to reduced flow blockage, and its sensitivity to flow disturbances increases.

Turbine flowmeters also improve the flow profile due to the effect of the fluid on the rotor. The performance of turbine flowmeters is also improved due to the improvement of the inlet flow profile. Because turbine flowmeters are sensitive to asymmetry in the velocity profile, AGA Report No. 7 requires turbine flowmeters to use rectifiers to eliminate flow vortices at the inlet.

Since ultrasonic flowmeters have essentially no obstructions that affect the flow of population, the flowmeter does not change the flow profile, and the flowmeter accurately determines the flow rate based on reliable calculation methods based on the flow sample obtained by the flowmeter.

In the design of multi-channel ultrasonic flowmeters, manufacturers try to optimize the flowmeter to reduce their sensitivity to flow disturbances. If the flowmeter can compensate for all flow disturbances, then the rectifier can be eliminated. However, since there is a small amount of published information on how rectifiers affect the performance of multi-channel ultrasonic flowmeters, there is still interest in the use of rectifiers in conjunction with ultrasonic flowmeters. Based on the application experience of other types of flowmeters, rectifiers represent potential benefits.

As an effective and beneficial alternative to multi-channel flowmeters, it also makes sense to use rectifiers with inexpensive mono-channel ultrasonic flowmeters. In addition, there is a small amount of reliable test data to confirm the performance of mono-channel flowmeters using rectifiers.

These results are obtained from the first part of the test, which attempts to determine the practical experience of 8-inch mono-channel and multi-channel ultrasonic flowmeters installed in different pipes and when used in conjunction with a rectifier. This test was conducted with one or two elbows upstream of the test flowmeter and with or without the flowmeter equipped with a rectifier.

Further tests were intended to evaluate the bidirectional flowmeter measurement performance and flow measurement accuracy at flow rates below 1% of the flowmeter capacity. Bidirectional measurement performance is of concern to those planning to install ultrasonic flowmeters where the flow can flow in both directions, such as underground gas storage facilities.

For a metering station installation, the number and size of flowmeters need to be determined, and low flow measurement performance should also be of concern because of the turndown ratio.

2. Test Method

The flowmeter was installed in a test section of the high pressure loop (HPL) and the test medium was transmission-grade natural gas. Data were collected simultaneously on the ultrasonic flowmeter and the critical flow nozzle set on the HPL, which served as a flow standard.

Five double-weighted sonic nozzles were calibrated in the field relative to the HPL weigh tank system at different pressures. For all calibrations, gas properties were determined by an online gas chromatograph and the AGA Report No. 8 equation of state.

The static pressure, related to the reference pressure of the HPL, was measured at two pipe diameters downstream of a flowmeter. The gas temperature is measured three pipe diameters downstream of each flowmeter. The measured temperature and pressure are used together with the measured gas composition and the gas volume measured by the ultrasonic flowmeter to calculate the mass flow rate of the ultrasonic flowmeter, which is then compared with the flow rate determined by the critical flow nozzle.

The ultrasonic flowmeter can obtain the volume flow rate in different ways, depending on the solution selected by the manufacturer. The calibration method inside the flowmeters M3 and M4 is used to calculate the total gas volume and the time during the operation. The average flow rate is then calculated based on the total amount. The

flowmeters M1 and M2 report (measure) the actual flow rate, providing a flow value once per second to determine the average volume flow rate. The state, velocity and sound velocity data of the individual channels are also recorded. A

typical test system consists of recirculating gas through the flow loop, and achieving gas temperature and pressure stability, selecting and switching different sonic nozzle combinations to determine the stable flow rate. A test point consists of the average value of the flow rate and other measurements calculated over a 90s period. A test point is repeated 6 times to calculate the average value and standard deviation. Measurement data are also collected by two turbine flowmeters. The data of the turbine flowmeter confirms the consistency of the experiment.

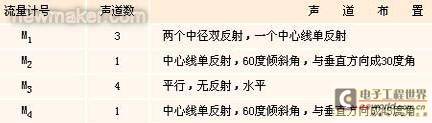

The four flow meters used in this test were provided by the manufacturer and are all commercially available. No flow calibration was done before the test of this project. There are two multi-channel flow meters and two single-channel flow meters. Table 1 shows the arrangement of the flow meter channels.

Table 1 Test flow meter geometric parameters

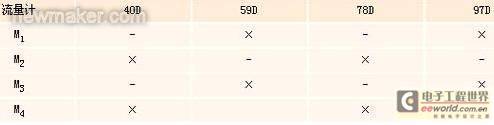

3. Basic Test Installation

The pipeline installation for the basic test is shown in Figure 1. All piping is made of 8 in ID No. 40 carbon steel pipe (7.981 in ID) with polished internal welds. The flowmeters tested are installed at 40D (D = 8 in), 59D, and 97D downstream of the 90° long-diameter elbow. A 12 in × 16 in × 10 in Sprenkle flow straightener is installed upstream of the elbow, followed by a 10 in × 8 in concentric reducer and a 43D 8 in straight pipe section until the elbow. Each flow meter can be tested in two of four axial positions (see Table 2).

Table 2 Test positions of flowmeter under reference conditions

Figure 1 Pipeline installation for basic flow test

4. Basic test results

The test performance of two multi-channel flowmeters (M1 and M3) under benchmark installation conditions is shown in Figures 2 and 3. The results are expressed as percentage error (relative to the MRFHPL critical flow nozzle) as a function of the average flow velocity through the flowmeter. A point represents the average of 6 repeated measurements at each flow rate, and the error band represents the 95% confidence level. For

flowmeter M1, all data fall within the 0.4% range when the velocity is greater than 10ft/s, regardless of velocity (see Figure 2). At flow rates below 10 ft/s, the error curve deflects upward. This may be caused by a positive zero offset or a deviation in the correction algorithm. This cannot be attributed entirely to the different velocity profiles at low flows. It may be a combination of the two effects.

Checking the zero flow of the flow meter indicates a zero drift of 0.01 ft/s. If the zero drift is removed, the upward deflection will be flattened, because the minimum velocity point (2.8 ft/s) has a drift of 0.35% and the point at 5.6 ft/s has a drift of 0.18%. In any case, this shows that the upward deflection of the curve cannot be attributed entirely to zero drift.

Figure 2 Basic flow measurement results of multi-channel flowmeter M1 [page]

measurement error of flowmeter M3 as a function of velocity through the flowmeter is shown in Figure 3. The nonlinear characteristics of the measurement error for this flowmeter differ from those observed in similar experiments with 12-in. flowmeters previously performed at the MRF (Grimly) and elsewhere (by Van Bloemendaal and Van der Kam). Only for the data collected at 400 lb/in2(A) for the flowmeter mounted at 59D, the error was within 0.3% for average velocities above 10 ft/s, with the error curve sloping downward as velocity increases.

Figure 3 Basic measurement results of multi-channel flow meter M3

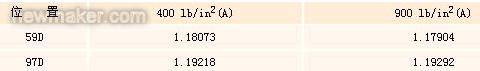

The data, including the suspect data set, remain within 0.5% error at velocities above 10 ft/s. These data also show that the flow measurement difference is 0.2% when the pressure increases from 400 lb/in2(A) to 900 lb/in2(A). When the flowmeters at 59D and 97D are compared, the actual results at 900 lb/in2(A) pressure differ by 0.1%. A

possible explanation for this difference is that the velocity profile continues to develop after 59D. A comparison of the individual channel velocity ratios shows that the velocity profile shape has improved. Table 3 shows the ratio of the center channel velocity (ultrasonic channel on the centerline of the pipeline axis) to the outer channel velocity at the maximum flow point for flowmeter M1. Similar calculated values for flowmeter M3 are shown in Table 4. Since flow meters have unique acoustic channel locations, comparisons should not be made between different flow meter types.

Table 3 Speed from center to outside of M1

Table 4 Velocity ratio of M3 center channel to outer channel

results of the single-channel flowmeter M2 (see Figure 4) with an offset of about -1.2% when installed at 78D and about -1.8% when installed at 40D show that the error value in the flow measurement is independent of pressure, but is related to axial position. The test error curves of the single-channel flowmeter M4 at two axial positions and two operating pressures are shown in Figure 5. The curves show an average deviation of 0.5%, which also shows that the line pressure has a greater impact on the measurement results than the distance between the 90° elbow and the flowmeter.

Figure 4 Basic measurement results of the mono-channel flow meter M2

Figure 5 Basic flow measurement results of the mono-channel flowmeter M4

V. The influence of installation on the test

The installation process of the test that has been implemented so far is shown in Figure 6. The mono-channel flowmeter was tested at two different locations 1 and 2 (10D and 19D downstream of a single 90° long-diameter L-shaped elbow). The multi-channel flowmeter was tested downstream of two flat-arranged elbows at locations 3 and 4 (10D and 19D downstream of the second L-shaped elbow).

Figure 6: Initial pipeline layout for upstream flow impact testing

VI. Effect of Installation on Test Results

These results are reported as deviations from the test results under reference conditions.

For multi-channel flow meters M1 and M3, the flow meters were installed 97D downstream of a single 90° elbow. The data obtained represent the test results under reference conditions. For single-channel flow meters M2 and M4, the flow meters were installed 78D downstream of the 90° elbow. The results obtained are used for the test results under reference conditions. The test results under reference conditions are the results that can be obtained with a process installation that is as close to the optimized one.

The results of the multi-channel flowmeter M1 at 10D downstream of the two flat elbows are shown in Figure 7. The test results show that the measurement error produced by the bare pipe installation is within 0.5% of the basic measurement result, and the relative error is in the order of 0.3% to 0.5%. The relative error occurs at high gas flow rates. There is no significant difference in the test results of the flowmeter installed 10D downstream of the second elbow, equipped with a 19-tube bundle rectifier and a GFC type rectifier. Above velocities of 20ft/s, both rectifiers reduce the relative error to at least 0.25%.

For velocities below 20ft/s, all results tend to converge, indicating that the flowmeter is either sensitive to the velocity profile produced by the installation arrangement or that there is no significant difference in the velocity profile effect within this velocity range. The determination of the planned velocity profile will help to explain these results, and it will also further explain the data collected related to the single channel velocity ratio.

The test results of the flowmeter M1 installed 19D downstream of the two flat elbows are shown in Figure 8. The relative measurement error of the bare tube and 19-tube bundle rectifier results is about 0.5%. When the flow meter is installed at 19D downstream of the elbow, the error of the bare tube measurement is slightly larger than the error of the flow meter installed at 10D. Above 10ft/s, the measurement results installed with the GFC are within 0.1% of the test results under the reference conditions. In addition, at low flow rates, the measurement results converge. [page]

Figure 7 Correlation performance of multiphase flow meter M1 with two elbows 10D apart and 10D downstream in the same plane

Figure 8 Correlation performance of multiphase flowmeter M1 with two elbows 10D apart and 19D downstream in the same plane

The results of the bare pipe installation condition tested by the flow meter M3 installed at 19D are shown in Figure 10, which are offset by about 0.2% compared with the flow meter data at the 10D position, and above 20 ft/s, they remain within 0.25% of the basic test results. Except for the highest flow rate, the data of the 19-tube bundle rectifier are close to agreement. For gas flow velocities above 45 ft/s, the measurement error produced by the GFC is closer to the error under the reference installation condition than the 19-tube bundle rectifier and bare pipe.

Figure 9 Figure 7 Correlation performance of multiphase flow meter M3 with two elbows 10D apart and 10D downstream in the same plane

Figure 10 Figure 7 Correlation performance of multiphase flowmeter M3 at 19D downstream of two elbows 10D apart in the same plane

test results of a single-channel flowmeter installed 10D and 19D downstream of a 90° long-diameter elbow are shown in Figure 11. The measurement results show that the error offset is about 2% to 2.2% relative to the test error under the baseline conditions installed 78D downstream of the 90° elbow. The additional error offset caused by rotating the flowmeter 90° about the axis is 1.3%.

Figure 11. Relevant performance of single-channel flow meter M2 downstream of a single 90° elbow

Figure 12 Relevant performance of single channel flow meter M4 downstream of a single 90° elbow

Flowmeter M4, which was mounted 19D downstream of the elbow, deviated by about 1.5% to 2% relative to the reference condition except for the 90° position, and the results are shown in Figure 12. Since the measurement channel is 45° from the vertical, this is probably the reason why the test results for this flowmeter are basically independent of its position. In this case, the channel position relative to the flow disturbance remains consistent despite the deflection of the axis center of the flowmeter body.

VII. Conclusion

The test under the reference condition shows that the fluid velocity profile is not fully developed at 59D downstream of a long-diameter 90° elbow, and the tested flowmeter is sensitive to the subsequent developing velocity profile. This shows that the accuracy of the tested 8-in. flowmeter can be improved by flow calibration.

The test results of the 8in multi-channel flowmeter show the potential benefits of using a rectifier to improve measurement accuracy.

The single-channel flowmeter test shows that it has the potential to obtain a measurement accuracy better than 0.5% under good flow field conditions. Tests with flowmeters installed 10D and 19D downstream of a single 90° elbow illustrate the sensitivity of the flowmeter to a simple disturbance. Relative to the test under baseline conditions, the flow measurement error range is 1% to 4%. The

experimental test results are only the beginning of a large test plan. A more in-depth analysis of the data obtained and other test data from this test plan will gain new insights into the performance of ultrasonic flowmeters in high-pressure natural gas applications. (end)

Previous article:Industrial CT density resolution test

Next article:Brief Discussion on the Measurement Method of Electromagnetic Interference of Military Relays

- Popular Resources

- Popular amplifiers

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Share: Should the circuit board use grid copper or solid copper?

- Highlight Review丨What hard-core technologies did ADI showcase at IMS 2019? Come and find out~

- Google Protobuf 库

- EEWORLD University ---- Wildfire LwIP Application Development Practical Guide

- Compile QT5.6.0

- How to consider and design ESD of RF modules?

- There seems to be something wrong with microPython's regular expression library ure. The matching result of the "*" wildcard is incorrect.

- Regarding IIC communication PCB routing, do I need differential routing? I am currently routing in a dispersed manner? Maximum frequency of 400K

- Decoupling Basics

- Communicate with device over wifi (Android)

Overview and design flow of Altera\'s storage solutions

Overview and design flow of Altera\'s storage solutions

京公网安备 11010802033920号

京公网安备 11010802033920号