BX series wavelength dispersive X-ray fluorescence analyzer is a high-tech product developed by Beijing Bangxin Weiye Technology Development Co., Ltd. on the basis of the national "Ninth Five-Year Plan" key project, summarizing the experience and lessons of my country's development of X-ray fluorescence analyzer over the years, absorbing international advanced technology, and conducting in-depth industrial research and development. All technical performance indicators have reached the advanced level of similar international products.

X-ray fluorescence spectrometry technology, as a conventional analytical method, began in the 1950s. After more than 50 years of development, it has now become one of the necessary methods for material composition analysis. With the continuous development and progress of analytical methods and related technologies (especially computer technology and electronic technology), X-ray fluorescence spectrometry has not only become an important analytical method in the fields of geology, metallurgy, petrochemicals, semiconductor industry, medicine and health, but also a fast, accurate and economical multi-element analysis method widely used in materials science, life science, environmental science, etc.; especially in the field of industrial conventional component analysis, X-ray fluorescence spectrometer is internationally recognized as the dominant analytical instrument, widely used in steel, metallurgy, building materials, petrochemicals, geology and mining and other material industries; at the same time, X-ray fluorescence spectrometer is the preferred instrument for field analysis and process control analysis.

For a long time, all wavelength dispersive X-ray fluorescence analyzers suitable for use by cement manufacturers have relied on imports; the expensive purchase costs, spare parts costs, maintenance and technical service costs have made my country's cement manufacturers overwhelmed; at the same time, the spare parts supply cycle of more than 8 weeks has had a serious impact on the normal production of cement plants.

The successful development of the BX series wavelength dispersive X-ray fluorescence analyzer has completely broken the monopoly of foreign instrument companies on this technology, and provided a high-performance and cost-effective process control solution for the majority of domestic cement production enterprises. It is superior to imported instruments in terms of technical support and technical services, while the related costs are much lower than imported instruments.

II. Project Content and Purpose and Significance of Project Implementation

The new dry process cement production technology is based on suspension preheating and pre-decomposition technology, and widely applies modern science and technology to the whole process of cement dry process production, making cement production efficient, high-quality, resource-saving, clean production, environmental protection requirements, large-scale process equipment, production control automation, and scientific management of modern cement production methods; among them, raw material batching and clinker calcination are the two core links of the whole production process. Generally speaking, in the new dry process cement production technology, in order to ensure the stability of the calcination process and improve the clinker output and quality of the kiln, the uniformity (stability) requirements of the raw materials and the control requirements of the content of each element are much more stringent than other kiln types; a lot of practical experience has also proved that only in this way can the advanced nature of the new dry process cement production technology be fully exerted and reflected.

Therefore, in the process design of the new dry process cement production line, higher requirements are put forward for the control indicators of various elements in the raw fuel:

1. Control the chemical composition of raw materials and avoid harmful substances from entering.

Since R2O (K2O + Na2O), SO3-2, and Cl- in raw materials will affect the crusting and clogging of the preheater decomposition furnace system in the new dry process production, after determining the type and proportion of raw materials, it is necessary to verify whether the harmful components in the raw materials meet the requirements at any time. Otherwise, it is necessary to consider changing the raw materials or rate values, or take bypass ventilation measures to reduce the adverse effects of the circulation enrichment of alkali, sulfur, and chlorine on the new dry process kiln system.

(1) Magnesium oxide (MgO)

When the clinker contains a small amount of MgO, it can reduce the burning temperature of the clinker, increase the amount of liquid phase, reduce the viscosity of the liquid phase, and facilitate the burning of the clinker; in silicate cement, the maximum content of MgO combined with the main clinker mineral phase is 2% (by mass). The part exceeding this amount is in a free state in the clinker, which causes the volume expansion and cracking of the hardened solid body.

(2) Free silica (f-SiO2)

Flint is a harmful impurity in the raw material. Flint causes serious wear and tear on the equipment and has an adverse effect on the kiln and mill operation.

(3) Chlorine

Chlorine mainly generates CaCl2 or alkali chloride in the firing system. Its volatility is particularly high. Almost all of it volatilizes again in the kiln. It condenses when it encounters cold at the outlet of the preheater, forming a chlorine and alkali cycle enrichment, causing the chloride content in the preheater raw material to increase by nearly 100 times, causing the preheater to be crusted and blocked. For this reason, the universal control threshold of chlorine content in raw materials internationally is ≤0.015%.

(4) Alkali (K2O + Na2O)

Alkali has two main effects on cement production: one is that it affects the normal production of the new dry clinker firing system; the other is that it affects the quality of clinker. Calcination of raw materials with too high alkali content is prone to cause crusting and blockage in the flue, decomposition furnace, and preheater; the sintering temperature range in the rotary kiln is narrowed, the thermal system is unstable, the flying sand is serious, the kiln skin is loose, and the life of the lining of the firing belt is shortened, resulting in a decline in the quality of the clinker. In serious cases, normal production will not be possible. If the alkali content of the clinker is too high, its setting time will be shortened, resulting in rapid setting, an increase in the water requirement of the standard consistency of cement, an increase in free calcium oxide in the clinker, poor stability, reduced flexural strength, and a slight increase in the compressive strength of 1 day and 3 days, while the compressive strength of 7 days and 28 days is significantly reduced.

(5) The sulfur

-alkali ratio is an important control indicator for the cement calcination process. If the SO2 content is too high, it is often easy to cause crusting and blockage in the preheater or ringing in the kiln; conversely, if the alkali content is too high, it will affect the normal operation of the preheater.

2. Control the fluctuation of various components of raw materials, strengthen the analysis and formulation of raw materials, and strictly control the fluctuation range of various rate values.

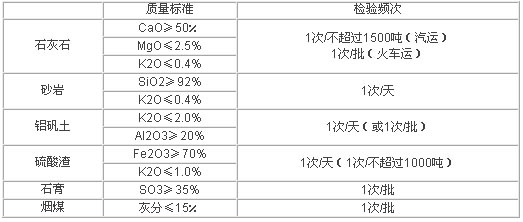

Table 1 Quality control standards for raw materials and fuels of a cement plant (part related to chemical composition analysis)

Table 2 Quality control standards for the new dry process of a cement plant (part related to chemical composition analysis)

In summary, in order to meet the requirements of the new dry process cement production process, the chemical composition of the raw materials and fuels in the production process must be analyzed and controlled in a timely and accurate manner. The traditional chemical analysis method can no longer meet the needs of the production process. At present, many new dry process cement plants are equipped with corresponding multi-channel X-ray fluorescence analyzers in order to achieve good quality control indicators. Due to the limitation of the analysis speed of chemical analysis methods, in fact, the use of chemical analysis methods only has the significance of post-monitoring for the production process, but not control. Often, when we find that there is a problem in a certain control link, it has already caused serious consequences and brought great losses to the factory. [page]

Take the raw material batching process as an example: the chemical analysis method generally performs a full analysis of raw materials once every 8 hours (a few cement production enterprises use a method once every 4 hours, but the labor intensity of the analysts is high, the number of people is large, and the cost is high). When there is a problem with the batching, it is generally not discovered until the full analysis results come out. At this time, it may have been several hours since the problem occurred. Even for a cement production line with a daily output of 1,000 tons, there will be hundreds of tons of problematic materials, which directly affects the stability of the calcination process. Especially for production lines using continuous raw material homogenization silos, the consequences of this situation are very serious. After using the X-ray fluorescence analyzer, we can provide accurate data of the full analysis of raw materials every hour (if necessary, every half an hour), so that the batching process, the target value of the batching and related equipment can be controlled, adjusted and monitored at any time to ensure the stability of the raw material composition entering the kiln, thereby ensuring the stability and continuity of the calcination process.

The purpose of using X-ray fluorescence analyzer is to make full use of its fast and accurate advantages to track and detect various raw materials, raw materials, clinker and cement throughout the whole process, and make real-time adjustments by DCS system according to different situations to achieve real pre- and in-process control; without the timely and accurate analysis data of each element in the material provided by X-ray fluorescence analyzer, DCS system cannot fully play its role. Therefore, the real significance of using X-ray fluorescence analyzer is to reduce process accidents, stabilize quality and increase production; at the same time, the use of X-ray fluorescence analyzer also helps to comprehensively strengthen and improve the overall management level of cement production enterprises, and can greatly reduce the number of analysts and save the cost of chemical reagents.

Table 3 Application examples: Application details of X-ray fluorescence analyzer in Beijing cement plant

1. From the table, we can see that the uses of instrument analysis results can be divided into three categories:

1. Directly used for production control: such as analysis of raw materials out of the mill, analysis of SO3 in cement out of the mill, analysis of coal powder, etc.

2. Used for production process monitoring: such as analysis of raw materials entering the kiln, analysis of cement components out of the mill (monitoring the amount of admixture added), clinker out of the kiln, etc. It can quickly discover errors or equipment failures in related process links.

3. Used for quality management: such as analysis of clinker out of the kiln, analysis of cement out of the factory, analysis of raw materials, etc.

2. Determine the type of measured elements:

In addition to SiO2, Al2O3, Fe2O3, and CaO, it is necessary to discuss with the factory's technical personnel and select any two elements from MgO, SO3, K2O, etc. according to the specific conditions of the raw materials and processes; if the MgO content in the limestone is not high, SO3 and K2O should be measured; if the MgO content in the limestone is high, MgO and SO3 should be determined as the measured elements;

4. Economic Benefit Analysis after Project Implementation

The economic benefits of cement production enterprises using X-ray fluorescence analyzers are by no means limited to saving chemicals and reducing the number of laboratory analysts; more importantly, the use of X-ray fluorescence analyzers can greatly reduce the occurrence of process accidents and quality accidents, greatly improve the normal operation rate of process equipment, and provide guarantees for increasing production and improving the strength grade of clinker; at the same time, by improving the clinker grade, the amount of admixture can be appropriately increased, directly reducing the cost of cement production. Therefore, it is difficult for us to specifically calculate the economic benefits generated by this; but what is certain is that X-ray fluorescence analyzers, as a core detection method in the control of cement production processes, are of indispensable importance to the entire process of cement production.

5. Subsequent technical support and technical services

X-ray fluorescence analyzer is a high-tech product involving many scientific fields such as nuclear physics, optics, mechanics, electronics, automatic control, computer technology, analytical chemistry, statistical physics, etc. As the end user, cement production enterprises cannot and do not need to fully and carefully understand the specific structure of the instrument, complex maintenance technology, etc. Instrument manufacturers have the responsibility and must provide users with timely, thoughtful and comprehensive technical support and technical services. Beijing Bangxin Weiye Company has many technical personnel from the China Building Materials Science Research Institute, who have a comprehensive understanding of the cement production process; therefore, they have a deep understanding not only of the instrument itself, but also of the actual application of the instrument in the cement production process; we have the ability to provide cement companies with the best instrument configuration plan and comprehensive technical support according to the different raw materials and process conditions of each cement production enterprise.

Previous article:納米技術保障高精度測量

Next article:Application of Ultrasonic Flowmeter in Coalbed Methane Flow Measurement

- Popular Resources

- Popular amplifiers

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- [Free trial of Pingtouge Bluetooth Mesh Gateway Development Kit] + Gateway module to cloud platform and problem solving

- 【Smart Kitchen】Environmental Sensor Schematic Design

- bq34110 cannot program parameters

- [Topmicro Intelligent Display Module Review] 7. Help with network communication issues

- Make your own wifi switch esp8266 lua development

- Bicycle modification series——by dcexpert

- Question: Which channel do you use to purchase components for your company's products?

- New opportunity to counterattack! Come to EEWorld Download Center, complete tasks to earn 200 points, and easily achieve point freedom

- Participate to get gifts | Keysight Technologies offers tips on how to balance new technology requirements with test costs

- Xunwei-IMX6Q development-non-device tree uboot-modify default environment variables

Selection of Excitation Frequency and Sensitivity Analysis in Pipeline Guided Wave Testing

Selection of Excitation Frequency and Sensitivity Analysis in Pipeline Guided Wave Testing

京公网安备 11010802033920号

京公网安备 11010802033920号