1. Defects of ordinary oxygen sensors

Ordinary oxygen sensors generally have 4 wires, 2 of which are heating wires, the third is a signal wire, and the other is a ground wire. It is a zirconium dioxide coating attached to both sides of the ceramic body, which can conduct oxygen ions at a temperature of 350°C or higher. The concentration difference of oxygen on both sides of the sensor causes a potential difference between the two surfaces, and the working curve is very steep. When the mixture is close to the theoretical air-fuel ratio, it outputs a voltage of 0.45V. When the exhaust gas is slightly rich, the output voltage suddenly changes to 0.6V~0.9V; on the contrary, when the exhaust gas becomes thinner, the output voltage suddenly changes to 0.3V~0.1V (Figure 1). Let's analyze: If the exhaust gas is further enriched, will the voltage of the oxygen sensor increase again? The output voltage of 0.9V has been capped. In addition, if the exhaust gas becomes thinner, will the voltage of the oxygen sensor decrease again? The output voltage of 0.1V is already the bottom. From the above analysis, it can be seen that ordinary oxygen sensors cannot measure excessively rich and thin exhaust gas. The two-state voltage signal of 0.1V to 0.9V is no longer sufficient for controlling automobile emissions. It can only detect the oxygen content of the exhaust gas within a relatively narrow range after the mixture is burned at a theoretical air-fuel ratio of 14.7:1, so this is the defect of ordinary oxygen sensors.

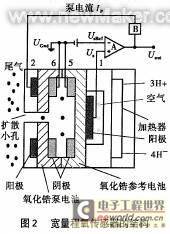

In order to overcome the defects of ordinary oxygen sensors, a new generation of wide-range oxygen sensors was born. The structure of the wide-range oxygen sensor is shown in Figure 2. It consists of an ordinary narrow-range concentration voltage type oxygen sensor (zirconium oxide reference cell , a limit current type oxygen sensor, and an aluminum oxide pump cell) and a diffusion hole and a diffusion chamber. It requires a specially designed sensor controller to control its normal operation. In Figure 2, the sensor controller is represented by A and B. The exhaust gas enters the diffusion chamber through the diffusion hole. The exhaust gas may be a rich mixture rich in oil or a lean mixture rich in oxygen. After the aluminum oxide reference cell senses the concentration of the exhaust gas, it generates a voltage Us. Depending on the concentration of the exhaust gas, the rich mixture rich in oil will generate a Us higher than the reference voltage UsRef. The sensor controller will generate a pump current Ip in one direction. The pump current Ip pumps oxygen into the diffusion chamber for chemical decomposition reaction, producing water and carbon monoxide and some oxides in the exhaust gas, which are attached to the surface of the pump oxygen element. In the chemical reaction, excessive hydrocarbons are decomposed, thereby reducing the concentration of exhaust gas and restoring the diffusion chamber to the equilibrium state of exhaust oxygen concentration with a Us voltage of 0.45V. On the contrary, the oxygen-rich lean mixture will produce a Us lower than the reference voltage UsRef, and the sensor controller will generate a reverse pump current Ip, which pumps oxygen out of the diffusion chamber. When the HC fuel or oxygen is neutralized, the voltage Us generated by the reference battery is equal to the reference voltage UsRef. At this time, the pump current IP reflects the concentration of the exhaust gas. The sensor controller converts the pump current IP into an output voltage Uout. By changing the polarity (current flow direction) and size of the pump current, the oxygen content of the exhaust gas in the diffusion chamber can be balanced. How to control this changing pump current again The adjustment of the injection time of the injector by the engine ECU is crucial. There is a DSP (digital signal processor) circuit in the control loop. The circuit has two outputs. One converts the changing pump current signal into a linear voltage by amplifying the analog-to-digital conversion. This voltage changes continuously from 0V to 5V to control the air-fuel ratio adjustment of the engine ECU. The other outputs a pulse width modulation signal to control the on and off time of the COM field effect switch transistor, providing current to the heater to heat the oxygen sensor.

There is only one item for the single-piece inspection of wide-range oxygen sensor: Terminals 3 and 4 are heaters, which should not be open circuited, and the voltage applied to them is 12V. Terminal 1 is the signal output, terminals 5 and 6 are the reference voltage, and terminal 2 is the pump current input. Some wide-range oxygen sensors have terminals 5 and 6 as the same terminal output.

The method of the maintenance station is to analyze by reading the data stream. Take the Bora as an example: the engine control unit converts the current signal of the wide-range oxygen sensor into a voltage value and displays it. The voltage specification value of the wide-range oxygen sensor is 1.0V~2.0V. When the voltage value is greater than 1.5V, the mixture is too lean (more oxygen), and when the voltage value is less than 1.5V, the mixture is too rich (less oxygen). When the voltage value is constant at 0V, 1.5V, and 4.9V, it means that the oxygen sensor circuit is faulty. The voltage peak observed with an oscilloscope may reach 4.9V, which is normal.

The voltage specification value of the aluminum oxide oxygen sensor is 0.0V~1.0V. When the voltage value is greater than 0.45V, the mixture is too rich; when the voltage value is less than 0.45V, the mixture is too lean; when the voltage value is 0V, 0.4V~0.5V, or a constant value of 1.1V, it indicates that there is a fault in the oxygen sensor circuit.

Reference address:Brief Analysis of Wide Range Oxygen Sensor for EFI Vehicles

Ordinary oxygen sensors generally have 4 wires, 2 of which are heating wires, the third is a signal wire, and the other is a ground wire. It is a zirconium dioxide coating attached to both sides of the ceramic body, which can conduct oxygen ions at a temperature of 350°C or higher. The concentration difference of oxygen on both sides of the sensor causes a potential difference between the two surfaces, and the working curve is very steep. When the mixture is close to the theoretical air-fuel ratio, it outputs a voltage of 0.45V. When the exhaust gas is slightly rich, the output voltage suddenly changes to 0.6V~0.9V; on the contrary, when the exhaust gas becomes thinner, the output voltage suddenly changes to 0.3V~0.1V (Figure 1). Let's analyze: If the exhaust gas is further enriched, will the voltage of the oxygen sensor increase again? The output voltage of 0.9V has been capped. In addition, if the exhaust gas becomes thinner, will the voltage of the oxygen sensor decrease again? The output voltage of 0.1V is already the bottom. From the above analysis, it can be seen that ordinary oxygen sensors cannot measure excessively rich and thin exhaust gas. The two-state voltage signal of 0.1V to 0.9V is no longer sufficient for controlling automobile emissions. It can only detect the oxygen content of the exhaust gas within a relatively narrow range after the mixture is burned at a theoretical air-fuel ratio of 14.7:1, so this is the defect of ordinary oxygen sensors.

In order to overcome the defects of ordinary oxygen sensors, a new generation of wide-range oxygen sensors was born. The structure of the wide-range oxygen sensor is shown in Figure 2. It consists of an ordinary narrow-range concentration voltage type oxygen sensor (zirconium oxide reference cell , a limit current type oxygen sensor, and an aluminum oxide pump cell) and a diffusion hole and a diffusion chamber. It requires a specially designed sensor controller to control its normal operation. In Figure 2, the sensor controller is represented by A and B. The exhaust gas enters the diffusion chamber through the diffusion hole. The exhaust gas may be a rich mixture rich in oil or a lean mixture rich in oxygen. After the aluminum oxide reference cell senses the concentration of the exhaust gas, it generates a voltage Us. Depending on the concentration of the exhaust gas, the rich mixture rich in oil will generate a Us higher than the reference voltage UsRef. The sensor controller will generate a pump current Ip in one direction. The pump current Ip pumps oxygen into the diffusion chamber for chemical decomposition reaction, producing water and carbon monoxide and some oxides in the exhaust gas, which are attached to the surface of the pump oxygen element. In the chemical reaction, excessive hydrocarbons are decomposed, thereby reducing the concentration of exhaust gas and restoring the diffusion chamber to the equilibrium state of exhaust oxygen concentration with a Us voltage of 0.45V. On the contrary, the oxygen-rich lean mixture will produce a Us lower than the reference voltage UsRef, and the sensor controller will generate a reverse pump current Ip, which pumps oxygen out of the diffusion chamber. When the HC fuel or oxygen is neutralized, the voltage Us generated by the reference battery is equal to the reference voltage UsRef. At this time, the pump current IP reflects the concentration of the exhaust gas. The sensor controller converts the pump current IP into an output voltage Uout. By changing the polarity (current flow direction) and size of the pump current, the oxygen content of the exhaust gas in the diffusion chamber can be balanced. How to control this changing pump current again The adjustment of the injection time of the injector by the engine ECU is crucial. There is a DSP (digital signal processor) circuit in the control loop. The circuit has two outputs. One converts the changing pump current signal into a linear voltage by amplifying the analog-to-digital conversion. This voltage changes continuously from 0V to 5V to control the air-fuel ratio adjustment of the engine ECU. The other outputs a pulse width modulation signal to control the on and off time of the COM field effect switch transistor, providing current to the heater to heat the oxygen sensor.

There is only one item for the single-piece inspection of wide-range oxygen sensor: Terminals 3 and 4 are heaters, which should not be open circuited, and the voltage applied to them is 12V. Terminal 1 is the signal output, terminals 5 and 6 are the reference voltage, and terminal 2 is the pump current input. Some wide-range oxygen sensors have terminals 5 and 6 as the same terminal output.

The method of the maintenance station is to analyze by reading the data stream. Take the Bora as an example: the engine control unit converts the current signal of the wide-range oxygen sensor into a voltage value and displays it. The voltage specification value of the wide-range oxygen sensor is 1.0V~2.0V. When the voltage value is greater than 1.5V, the mixture is too lean (more oxygen), and when the voltage value is less than 1.5V, the mixture is too rich (less oxygen). When the voltage value is constant at 0V, 1.5V, and 4.9V, it means that the oxygen sensor circuit is faulty. The voltage peak observed with an oscilloscope may reach 4.9V, which is normal.

The voltage specification value of the aluminum oxide oxygen sensor is 0.0V~1.0V. When the voltage value is greater than 0.45V, the mixture is too rich; when the voltage value is less than 0.45V, the mixture is too lean; when the voltage value is 0V, 0.4V~0.5V, or a constant value of 1.1V, it indicates that there is a fault in the oxygen sensor circuit.

Previous article:Application of sensor technology in the automotive industry

Next article:Driving force and trend of automotive sensor development

- Popular Resources

- Popular amplifiers

Latest sensor Articles

- Melexis launches ultra-low power automotive contactless micro-power switch chip

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Milestone! SmartSens CMOS image sensor chip shipments exceed 100 million units in a single month!

- Taishi Micro released the ultra-high integration automotive touch chip TCAE10

- The first of its kind in the world: a high-spectral real-time imaging device with 100 channels and 1 million pixels independently developed by Chinese scientists

- Melexis Launches Breakthrough Arcminaxis™ Position Sensing Technology and Products for Robotic Joints

- ams and OSRAM held a roundtable forum at the China Development Center: Close to local customer needs, leading the new direction of the intelligent era

- Optimizing Vision System Power Consumption Using Wake-on-Motion

- Infineon Technologies Expands Leading REAL3™ Time-of-Flight Portfolio with New Automotive-Qualified Laser Driver IC

MoreSelected Circuit Diagrams

MorePopular Articles

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

MoreDaily News

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

Guess you like

- TFT LCD Display Principle

- Voltage follower composed of op amp

- What sampling rate is required for an oscilloscope to measure various types of signals?

- Application of wireless Bluetooth transparent transmission modules in five common industries

- Do I need to set the pull-up or pull-down resistor of the port for output?

- There are 20 prizes left to be drawn: Watch the video "Avoiding Common AC-DC Design Pitfalls" and win a prize

- What should electronics beginners learn? What are the topics worth learning? And in what order should they learn them?

- Use STVP to encrypt and remove write protection for STM8

- What is interval timer mode?

- The third stage of automatic wiring results in the realization of full-scale or partial automatic copper plating

MAX4231ESA

MAX4231ESA

京公网安备 11010802033920号

京公网安备 11010802033920号