Want clinical-grade PPG for your wearable device? Just look here

On the feature list of health and fitness wearables, heart rate (HR) and blood oxygen saturation (SpO2) are rapidly moving from the "want to have" stage to the "hopeful to have" stage. However, this shift resulted in a decrease in read quality. This is because some sensor manufacturers are eager to meet market demand and have relaxed product quality, raising questions about product accuracy. While reading accuracy may be less critical for wearables used in daily life, on clinical-grade wearables the quality and integrity of the measurements must be reliable. Designers therefore face a key challenge: How to make high-quality HR and SpO2 measurements without draining too much device battery power? In this article, Analog Devices explains why traditional optical readout methods waste power and provides a low-power sensor IC using a new architecture that can perform clinical-grade measurements.

Figure 1. Measuring HR and SpO2 using a wrist-worn device

Photoplethysmography (PPG)

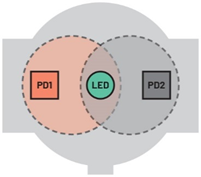

ADI uses an optical technology called photoplethysmography, or PPG, to measure HR and SpO2 (Figure 1). The PPG signal is obtained by detecting changes in light intensity reflected from blood vessels below the surface (Figure 2) by illuminating the skin with a light-emitting diode (LED) and using a photodiode (PD) to generate a current proportional to the amount of light received.

Figure 2. PPG measurement using LED and PD

The current signal is conditioned by the PPG analog front end (AFE) and then converted by the ADC for processing by the optical algorithm running on the system's microcontroller. In principle, a single LED-PD pair is sufficient for PPG measurements, and this configuration is common in clinical devices (Figure 3).

Figure 3. Measuring SpO2 and HR in a clinical setting

Nonetheless, the environments in which these devices operate are completely different from those found in daily life. First, the patient remains motionless and measurements are taken by a sensor clipped to the patient's fingertip. The lighting conditions are relatively stable, which will simplify the light detection of the PD. These devices are generally powered by the main power supply, so there is no need to worry about power consumption.

In contrast, wearable devices are generally worn on the wrist, which means that the degree of contact with the skin varies, generally depending on personal preference (tightness of the wristband) and the wearer's movements. Lighting conditions can vary greatly from day to day depending on location and time of day, and these devices are battery powered, so the sensor's current draw must be kept as low as possible. Additionally, different wearers have different skin tones, making the problem even more challenging. Dark skin has been described to have a lower perfusion index than light skin, meaning greater illumination intensity is required to make measurements (requiring the sensor to consume more power). Next, look at the advantages of different AFE structures for making PPG measurements.

PPG AFE with single ADC channel

Increasing the LED current or using two LEDs is a very intuitive way to increase the intensity of skin irradiation (Figure 4), which will increase the irradiation area of the skin. However, this method is very power-hungry, as the LED current accounts for at least 50% of the total power consumption of the PPG system, and depending on the wearer's skin perfusion index, the average power consumption may reach 1mW. Overall, this approach is inefficient and detrimental to battery life.

Figure 4. Using two LEDs to increase skin illumination intensity

PPG AFE with two ADC channels

Of course, a better way to increase the amount of skin exposure is to use an LED containing two PDs, which can be used to detect more reflected light (Figure 5).

Figure 5. Using an LED containing two PDs to improve light detection

The advantage is that the standard 20mA LED current can be reduced to 10mA compared to using a single PD, resulting in the same level of total PD current. Under challenging operating conditions (low skin perfusion and/or when the wearer is moving), the system algorithm determines that higher LED current is required, at which point system sensitivity increases proportionally. For example, using the same LED current as before, the PD current provided will be twice as much, which will achieve higher overall sensitivity, although the power cost will increase.

PPG AFE with four ADC channels

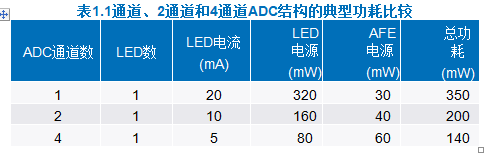

Using four PDs (requiring a quad-channel ADC) to detect reflected light can save even more power (Figure 6) because the LEDs can run at lower power (Table 1).

Figure 6. PPG measurement using one LED and four PDs

Table 1 summarizes the relative power consumption of the various architectures considered previously, assuming a typical supply voltage of 1.6V.

This structure provides higher-quality readings because blood vessels and bones are distributed asymmetrically around the wrist, and the four PDs can help eliminate the effects of movement and tightness of the device. Four PD receivers also increase the probability of detecting light reflected from the illuminated blood vessel. The graph in Figure 7 shows HR measured using 4 photodiodes (configured as two independent pairs: LEDC1 and LEDC2) compared to a reference measurement (polar). Wearable devices need to ensure good skin contact during measurements. Initially, the wearer rests and then starts exercising after 5 minutes (300 seconds), causing their HR to begin to rise. It is obvious that the signals on LEDC1 and LEDC2 deviate from the reference measurement to different degrees, so it is beneficial to use two pairs of PDs to capture the signal and take all these deviations into account.

Figure 7. HR readings obtained when using two independent pairs of PDs

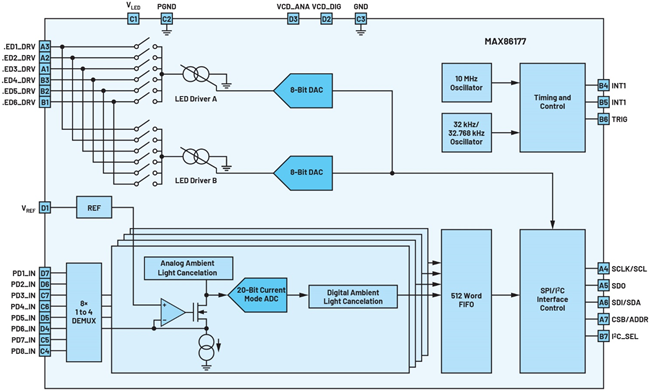

Figure 8. Block diagram of the MAX86177 quad-channel optical AFE.

Practical Quad-Channel ADC Solution

The MAX86177 (Figure 8) is an ultra-low-power, quad-channel optical data acquisition system with transmit and receive channels ideal for use in clinical-grade (as well as general-purpose) portable and wearable devices . Its transmitter integrates two high-current 8-bit programmable LED drivers, supporting up to 6 LEDs. The receiver integrates 4 low-noise charge integrating front ends, each containing an independent 20-bit ADC that can multiplex input signals from 8 PDs (configured as four independent pairs). It achieves a dynamic range of 118dB and provides up to 90dB of ambient light cancellation (ALC) at 120Hz. The main power supply voltage is 1.8V, and the LED driving power supply voltage is 3.1V to 5.5V. The device provides fully autonomous support for I2C and SPI compatible interfaces. The MAX86177 is available in a 2.83mm × 1.89mm, 28-pin (7×4) wafer-level package (WLP) and operates over the –40ºC to +85ºC temperature range. Laboratory test samples of this AFE showed an overall root mean square error of 3.12% for hypoxia measurements, which is within the 3.5% limit set by the FDA for clinical-grade monitors.

in conclusion

A major challenge facing designers of clinical-grade wearable devices is how to perform optical PPG measurements to obtain HR and SpO2 values without significantly draining the device's battery life. It can be seen in ADI's design solution that the four-channel ADC structure can save up to 60% of power compared to the basic structure using a single LED and PD. The MAX86177's quad-channel architecture in a small package is ideal for use in finger, wrist, and ear-worn wearable devices for clinical-grade HR and SpO2 measurements. It can also be used to measure body water content, muscle and tissue oxygen saturation (SmO2 and StO2), and maximum oxygen consumption (VO2max).

Previous article:Molex "Wearable Diagnostic Devices: A Global Survey on the Future of Medical Monitoring"

Next article:Multi-modal vital sign monitoring front-end helps solve the "involution" dilemma of wearable electronic products

Recommended ReadingLatest update time:2024-11-16 14:29

- e-Network Community and NXP launch Smart Space Building Automation Challenge

- The Internet of Things helps electric vehicle charging facilities move into the future

- Nordic Semiconductor Launches nRF54L15, nRF54L10 and nRF54L05 Next Generation Wireless SoCs

- Face detection based on camera capture video in OPENCV - Mir NXP i.MX93 development board

- The UK tests drones equipped with nervous systems: no need to frequently land for inspection

- The power of ultra-wideband: reshaping the automotive, mobile and industrial IoT experience

- STMicroelectronics launches highly adaptable and easy-to-connect dual-radio IoT module for metering and asset tracking applications

- This year, the number of IoT connections in my country is expected to exceed 3 billion

- Infineon Technologies SECORA™ Pay Bio Enhances Convenience and Trust in Contactless Biometric Payments

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- How to enable TI 15.4-Stack to support 470M frequency band

- EEWORLD University - SimpleLink Wi-Fi CC3120 Project Introduction

- OC5501-OC5502-LED automotive high and low beam solutions (no diode design, applied to automotive lights, MR16, architectural lighting)

- I would like to ask you guys, do I need to draw PCB in electronic competitions?

- stm32f407 driver enc28j60

- LM3478 step-down problem

- Does anyone understand the PD power supply protocol? USB Type-C PD power supply problem!

- C2000 MCU implements grid-connected micro solar inverter

- EEWORLD University Hall----Microcomputer Principles and System Design

- EEWORLD University Hall----RF Amplifier Design Tian Qingcheng, Chinese University, Taiwan

New concept analog circuit 1-5

New concept analog circuit 1-5 \"New Concept Analog Circuit\" - Transistor [Text Version] (Yang Jianguo)

\"New Concept Analog Circuit\" - Transistor [Text Version] (Yang Jianguo)

京公网安备 11010802033920号

京公网安备 11010802033920号