TPS274C65 helps reduce downtime and increase productivity in 24 VDC power distribution plants

Source: InternetPublisher:桂花蒸 Keywords: VDC VDC power distribution Updated: 2025/01/16

In the era of Industry 4.0, the amount of diagnostic data increases year by year, making systems smarter, able to stay online longer, and ultimately improving productivity. In the programmable logic controller (PLC) system, robotics and machine tool industry, one area where diagnostic data is still traditionally lacking is the 24 VDC power supply, which is used to distribute power to different control systems in the factory.

If a problem occurs with 24 VDC power distribution, the lack of load diagnostic data often results in lengthy debugging that involves basic steps (like “is the power OK LED green or red?”) or invasive investigations (like module removal), which increases downtime and reduces productivity.

Current sensing is a load diagnostic that, when added to a 24 VDC distribution network, improves data collection, making it possible to diagnose overcurrent, broken wires and aged mechanical systems, or to identify if a load was turned on properly.

The ability to sense current is readily available through an analog-to-digital converter (ADC) and a current sense amplifier or a high-side switch with integrated current monitoring. However, current sensing is difficult and costly to implement due to factors such as the isolation barrier, limited ADC channel count, or ADC channel routing.

One way to implement current sensing without overcomplicating the system is to use a high-side switch with an integrated ADC. The TPS274C65 is available in a 6mm x 6mm square flat leadless package that contains four 65 mΩ high-side switches, which reduces power dissipation by 38% compared to similar industrial high-side switches on the market. The high-side switch channels and ADC can be controlled and configured through serial protocol interface communication. The integration of current sensing circuitry and ADC in the TPS274C65 enables it to transmit current sensing data across the isolation barrier in the digital output module, reducing the routing of the ADC channels because all routing occurs inside the chip. In addition, the device can detect the temperature of the internal metal oxide semiconductor field effect transistor (MOSFET) and detect input and output voltages.

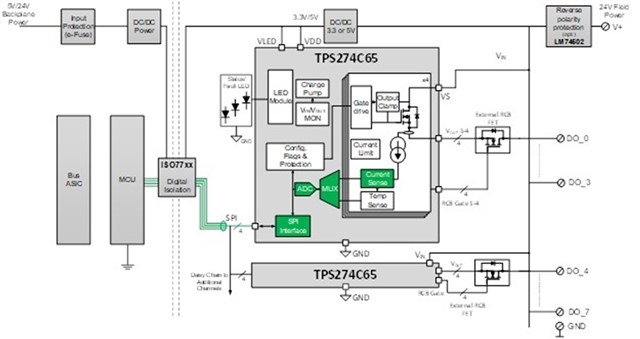

The block diagram in Figure 1 illustrates how the TPS274C65 in a digital output module can help increase the amount of data sent across the isolation barrier back to the PLC controller.

Figure 1: Application of TPS274C65 in digital output module

Now, let’s look at the TPS274C65 in factory applications such as digital outputs, remote input/output (I/O) modules, and larger systems such as robotics, computer numerical control machine tools, and multicarrier systems.

Shorten commissioning time with current sensing

As mentioned above, without diagnostic data, repairing a system may require time-consuming debugging or invasive investigations such as module removal. This is more difficult for complex systems such as robots and machine tools. The integrated ADC in the TPS274C65 enables on-site and remote checks to determine the correct power distribution of different sensors, relays, and subsystems, which helps eliminate potential root causes and allows users to identify problems faster. This type of monitoring also allows users to know if a subsystem fails, for example, so they can bring spare parts if on-site debugging is required.

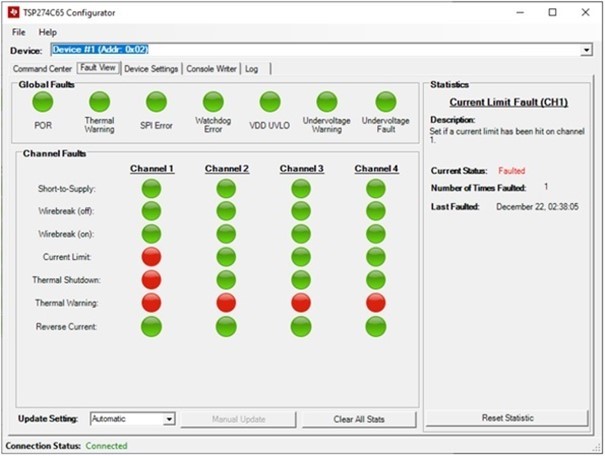

Figure 2 shows a digital output, remote I/O, and power distribution network command center in a machine or robotic application. This level of detail helps provide more information to help find the root cause of a system going offline.

Figure 2: TPS274C65USB evaluation module GUI

Current sensing enables predictive maintenance and predictive solutions to prevent problems before they occur

Going a step further, having diagnostic data that shows how a system operated before a failure can build a predictive resolution program to prevent future machines from experiencing the same failure. For example, current sensing can determine if a small motor or actuator is drawing more current to perform the same function, which could mean it is showing signs of aging, approaching failure, or that some mechanism may need repair.

The TPS274C65's integrated ADC can collect this data to perform predictive maintenance and predictive solutions to ensure that downtime is planned. For example, capturing the load current profile of a solenoid valve can detect if its performance has changed over time. Can the solenoid continue to be used, or does it need to be replaced?

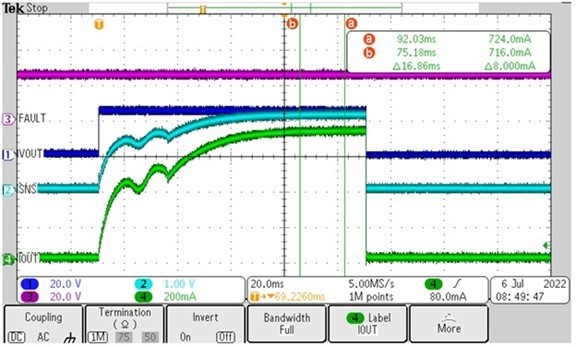

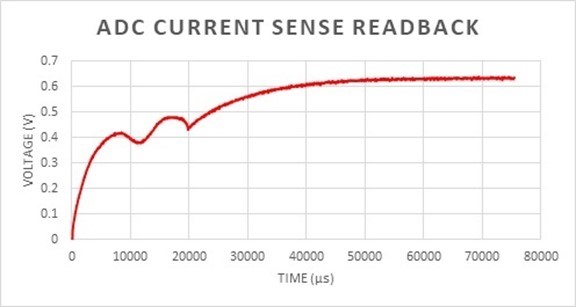

Figure 3 shows how the integrated ADC detects the load current profile of the solenoid valve.

(a)

(b)

Figure 3: Example of the TPS274C65 current sensing function: Oscilloscope screenshot showing solenoid load current profile (a); Solenoid load current profile read out from the TPS274C65 ADC

(b)

Conclusion

TPS274C65

Current sensing for factory automation systems can help reduce downtime and increase productivity. The bottom line is that by having this tool in your toolbox, you can make power distribution smarter.

- 5 Converter Topologies for Integrated Solar and Storage Systems

- Build a simple buck-boost regulator and test it on a breadboard

- Using Lead-acid Battery as Power Source for Walkman

- Practical and convenient fax machine power supply control circuit

- Boost drive circuit composed of RT8450

- A small and easy-to-make fast charger

- USB power socket using the car battery

- Mc34063 MP3 Switching Charger

- Car Audio Power Supply

- Automatic charger made with LM3914

- Excellent performance household inverter power supply circuit

- 24V power supply pure flat display high voltage power supply circuit diagram

- Portable device charging power circuit design

- Voltage stabilization control circuit in power circuit

- Power circuit with smoothing filter capacitor

- Large range 7~40V to 5VDC-DC step-down principle circuit diagram

- Transistor stabilized current power supply circuit 2

- Low voltage adjustable reference power circuit

- Common power circuits and applications 08

- Small power UPS power circuit and production

京公网安备 11010802033920号

京公网安备 11010802033920号