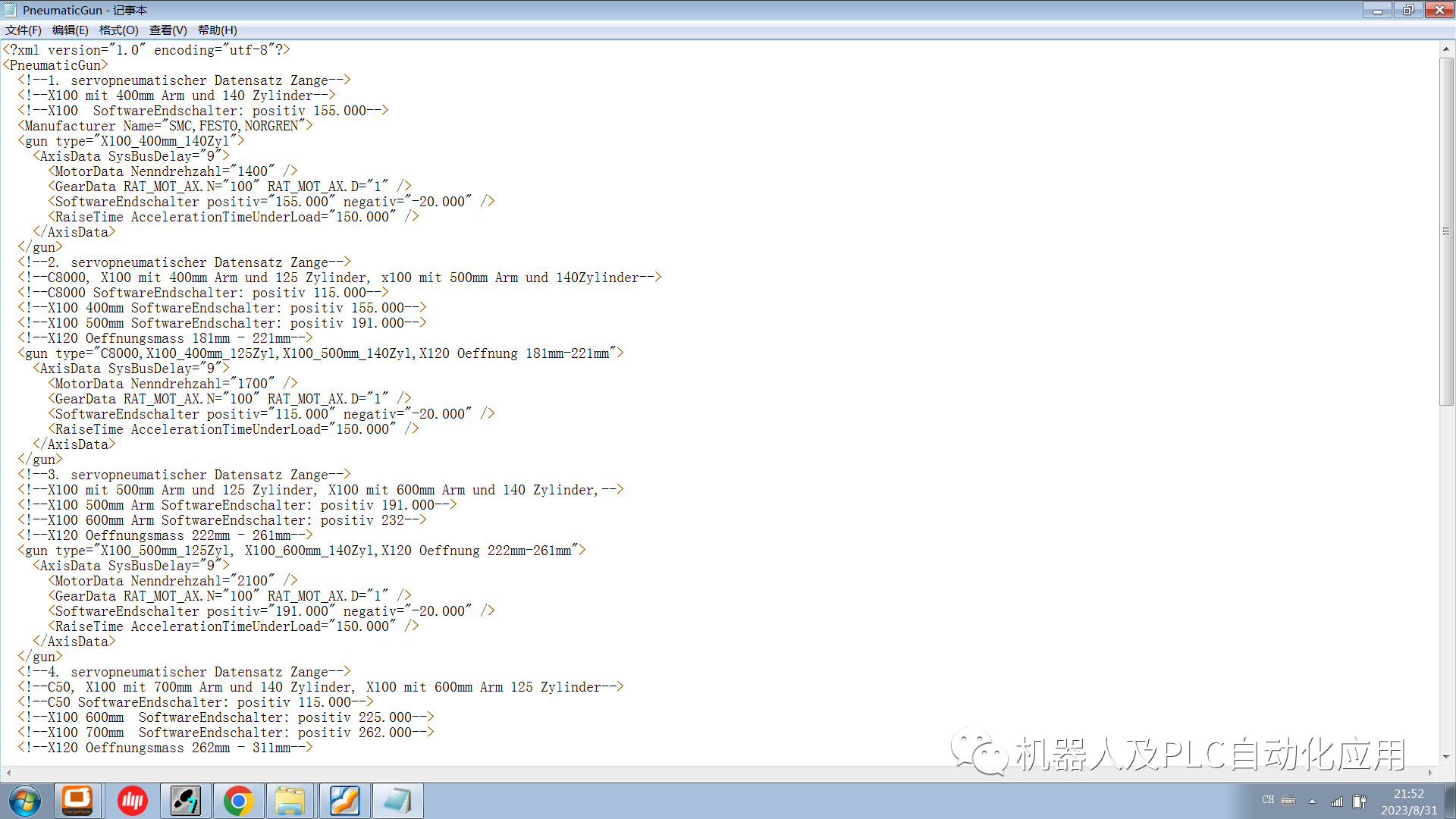

$softp_end is set by the software when it is installed

Generate EMZ selection box and select welding tongs

DEFFCT INT SetDlgMsg()

DECL KrlMsg_T Msg

DECL KrlMsgPar_T Par[3]

DECL KrlMsgOpt_T Opt

DECL KrlMsgDlgSK_T SK[7]

INT nHandle, nAnswer

Execute EMZ in T2 mode

Msg = { Modul[] "vw_emz", Nr 10, Msg_txt[] "Antriebsschnittstelle selektieren"} Prompt message bar "EMZ uses the tool number for measurement"

SK[1]={ Sk_Type #VALUE, Sk_txt[] "1"} Generated option button

SK[2]={ Sk_Type #VALUE, Sk_txt[] "2"}

SK[3]={ Sk_Type #VALUE, Sk_txt[] "3"}

SK[4]={ Sk_Type #VALUE, Sk_txt[] "4"}

SK[5]={ Sk_Type #VALUE, Sk_txt[] "5"}

SK[6]={ Sk_Type #VALUE, Sk_txt[] "6"}

SK[7]={ Sk_Type #VALUE, Sk_txt[] "7"}

Choose the welding tongs

Opt = { VL_Stop True, Clear_P_Reset True, Log_To_DB FALSE } Information property settings

nHandle = Set_KrlDlg (Msg, Par[],SK[], Opt) Activate message prompt

If (nHandle>0)Then

While (Exists_KrlDlg(nHandle, nAnswer)) Close the dialog window

Wait sec 0.1

Someone

Endif

Return(nAnswer) The value of the selected button is emitted

;

ENDFCT

/////////////////////////////////////////////////////////////

Declaration: 3 position variables, a real variable and an integer variable

E6AXIS GunPosAct, GunPosOpen, GunPosClose

REAL ActPos

INT what

VerBootfile=$softplcint[22]

while VerBootfile << span=""> 420

VwEmzMessage(7,#QuitMsg)

halt

old man

Generation of alarm information

repeat

DiNum=SetDlgMsg() A prompt box appears and select the return value 1-7

EaxNum = $softplcint[DiNum] - 6 Calculation of welding clamp number: $softplcint[1]=7

if (($softplcint[DiNum] > 6) AND ($softplcint[DiNum]<< span=""> 13)) then

EaxNum = $softplcint[DiNum] - 6

else

VwEmzMessage(6,#NotifyMsg) If no selection is made, a message prompt will be issued

halt

endif

until EaxNum>0 with 1 welding clamp EaxNum=1

GunPosAct=$axis_act saves the current axis information to the current position variable

GunPosOpen=$axis_act saves the current axis information to the current welding gun opening position variable

GunPosClose=$axis_act Save the current axis information to the current welding gun closing position variable

SWITCH EaxNum Select the axis number corresponding to the clamp number.

CASE 0 If the clamp number entered is 0

HALT means stop

CASE 1 Clamp No. 1

GunPosOpen.E1=$softp_end[7]-20 Calculate the opening of the E1 axis at the opening position of the welding clamp $SOFTP_END[7]=120.0 -20

GunPosClose.E1=10 Calculate the closing degree of the E1 axis at the closed position of the welding gun 10 mm

CASE 2 Clamp No. 2

GunPosOpen.E2=$softp_end[8]-20 Get the maximum opening position

GunPosClose.E2=10 Close position

CASE 3 Clamp No. 3

GunPosOpen.E3=$softp_end[9]-20

GunPosClose.E3=10

CASE 4 Clamp No. 4

GunPosOpen.E4=$softp_end[10]-20

GunPosClose.E4=10

CASE 5 Clamp No. 5

GunPosOpen.E5=$softp_end[11]-20

GunPosClose.E5=10

CASE 6 Clamp No. 6

GunPosOpen.E6=$softp_end[12]-20

GunPosClose.E6=10

DEFAULT Stop the program after exceeding the input clamp number 6

HALT

ENDSWITCH End selection control

IF $MODE_OP==#T1 THEN When the robot's working mode changes to T1 mode

VwEmzMessage(3,#NotifyMsg) Prompt message: Wrong working mode, use T2 or external automatic

Repeat the loop prompt until the robot's working mode is not T1

wait sec 0.1

until ($mode_op<>#t1) until statement

ENDIF

IF $MODE_OP==#EX THEN External automatic mode

IF $OV_PRO<>100 THEN Robot is not at 100% speed

MerkOvPro = $OV_PRO

$OV_PRO=100 restores to 100% speed

ENDIF

ELSE is not an external automatic mode

IF $OV_PRO<>100 THEN Robot is not at 100% speed

VwEmzMessage(4,#NotifyMsg) prompt message: Robot speed must be 100%

repeat

wait sec 0.1

until ($ov_pro==100) until the robot speed reaches 100%

ENDIF

ENDIF

PTP $AXIS_ACT moves to the current position

PTP GunPosClose GunPosClose position

ActPos=GetActPos(DiNum) Get the current external axis position parameter

;-----------------------------------------------------------

DEFFCT REAL GetActPos(di:in)

INT of

REAL RetGunPos

REAL GunPos[7];

GunPos[1]=sig1_istpos Get the actual position of welding gun No. 1

GunPos[2]=sig2_istpos

GunPos[3]=sig3_istpos

GunPos[4]=sig4_istpos

GunPos[5]=sig5_istpos

GunPos[6]=sig6_istpos

GunPos[7]=sig7_istpos

SIGNAL sig1_sollpos $out[737] TO $out[751]

SIGNAL sig1_istpos $in[737] TO $in[751]

RetGunPos=GunPos[di] / 10 Expression of position feedback value

IF $IN[Sign[di]] THEN If there is E752, the expression of the position will be changed to another one.

RetGunPos=RetGunPos * (-1)

ENDIF

;

RETURN(RetGunPos)

ENDFCT

---------------------------ENDFCT-----------------------

IF ABS(10-ActPos) > 1 THEN

The deviation range of the feedback value of the external axis shall not be less than 5 ABS takes the absolute value, so we can determine that the opening of the welding clamp is 10mm when closing, and the deviation between the theoretical value and the actual value cannot exceed 1mm.

VwEmzMessage(5,#QuitMsg,EaxNum) Prompt message: The external axis information is incorrect

WHILE (ABS(10-ActPos) > 1) The loop starts when the opening deviation value is greater than 1.

wait sec 0.2

I'M IN THE HOUSE

ENDIF

$softplcint[20]=DiNum 例: $softplcint[20]=1

FOR co = 1 TO 10 Loop 10 times to open the switch to the small port

PTP GunPosOpen------------Operating welding gun opening position

PTP GunPosClose C_PTP ---------operating welding gun closed position

ENDFOR

$softplcint[20]=-10 changes the value of $softplcint[20]

PTP GunPosAct Return to the starting position

WAIT SEC 0.2 Wait for 0.2 seconds

$softplcint[20]=0

TotzeitAlt = SysBusDelay[EaxNum] Save the last time value

TotzeitNeu = $softplcint[31] Get the time value of this calculation

SysBusDelay[EaxNum] = TotzeitNeu Save the current time value to SysBusDelay[]

$softplcint[EaxNum+7]=TotzeitNeu Save the current time value to the soft PLC

FOR co = 1 TO 20

IpoVerteilung[co]=$softplcint[99+co]

ENDFOR Assign to array

TraceTime.YEAR=$Date.YEAR records year, month, day, hour, minute, and second

TraceTime.MONTH=$Date.MONTH

TraceTime.DAY=$Date.DAY

TraceTime.HOUR=$Date.HOUR

TraceTime.MIN=$Date.MIN

TraceTime.SEC=$Date.SEC

RobSn=$KR_SERIALNO $KR_SERIALNO : The serial number of the robot is stored in the RDC card

TraceLength=$softplcint[34]

IF $mode_op <> #EX THEN The robot is not in external automatic mode

VwEmzMessage(1,#NotifyMsg,DiNum) Prompt message: The last debugging time is TotzeitAlt times 12 ms, etc.

VwEmzMessage(2,#NotifyMsg,DiNum) Prompt message: The debugging time is TotzeitNeu times 12 ms or so

ENDIF

Calculate the difference time and give it to the soft PLC

Pull overtravel fault:

GLOBAL REAL max_sf=15.0 Maximum deviation value

$softplcreal[20]=max_sf

sf_prog_status Delayed fault program status

$ASYNC_STATE Additional axis status

Therefore, we can conclude that one of the two control units of the pulling fault is the difference value max_sf=15.0, and the other difference time TotzeitNeu is given to the PLC. Therefore, the conditions for the pulling fault in the program are generated.

Other command functions in EMZ:

------------VwEmzMessage----------Volkswagen EMZ message-

DEF VwEmzMessage(msg_nr :IN, MsgTyp :IN, Param :IN )

INT msg_nr, msgtypnr, Param

DECL _MsgType MsgTyp

DECL KrlMsg_T USER_MSG

DECL KrlMsgPar_T Par[3]

DECL KrlMsgOpt_T Opt

DECL State_T st_ausg

INT nHandle, Answer, offset

USER_MSG = { Modul[] "vw_emz", Nr -1, Msg_txt[] " "} prompt message format

Opt = { VL_Stop False, Clear_P_Reset False, Log_To_DB TRUE }

IF Varstate("Param")==#initialized then

Get the state of the input variable "Param" if it is initialized

SWITCH Param

CASE 1

Par[1] = { Par_type #Value, Par_int 1 }

CASE 2

Par[1] = { Par_type #Value, Par_int 2 }

CASE 3

Par[1] = { Par_type #Value, Par_int 3 }

CASE 4

Par[1] = { Par_type #Value, Par_int 4 }

CASE 5

Par[1] = { Par_type #Value, Par_int 5 }

CASE 6

Par[1] = { Par_type #Value, Par_int 6 }

CASE 7

Par[1] = { Par_type #Value, Par_int 7 }

DEFAULT

Par[1] = { Par_type #Value, Par_txt[] " " }

ENDSWITCH

ELSE

Par[1] = { Par_type #Value, Par_txt[] " " }

ENDIF

IF NOT MsgIsSet(msg_nr) THEN If the feedback value of the message category is not set by MsgIsSet

USER_MSG.Nr = msg_nr message number

SWITCH msg_nr

CASE 1 Information prompt number 1

OFFSET=0

SWRITE(USER_MSG.MSG_TXT[],ST_AUSG,OFFSET,"Totzeit Achse%d vor Testlauf= %d *12ms",(EaxNum+6), TotzeitAlt) Timeline before test run

CASE 2 Information prompt number 2

OFFSET=0

SWRITE(user_msg.msg_TXT[],ST_AUSG,OFFSET,"Totzeit Achse%d nach Testlauf= %d *12ms ",(EaxNum+6), TotzeitNeu) Timeline after the test run

CASE 3 Information prompt number 3

USER_MSG.MSG_TXT[]="false Betriebsart - T2 or EXT incorrectly" Wrong operating mode - T2 or EXT required

CASE 4 Information prompt number 4

USER_MSG.MSG_TXT[]="Override auf 100% erforderlich" needs to be overwritten to 100%

CASE 5 Information prompt number 5

USER_MSG.MSG_TXT[]="Externe Achse%1 follows" External axis%1 does not follow

CASE 6 Information prompt number 6

USER_MSG.MSG_TXT[]="Unassigned additional axis - Additional axis"

CASE 7 Information prompt number 7

USER_MSG.MSG_TXT[]="Version bootfile is not supported"

Unsupported version startup file

DEFAULT

USER_MSG.MSG_TXT[]="unknown message" unknown message

ENDSWITCH

SWITCH MsgTyp starts displaying messages

CASE #StateMsg

nMsgHandle[msg_nr] = Set_KrlMsg (#State, USER_MSG, Par[], Opt)

; Status message output

CASE #QuitMsg

Previous article:Let you know what a perfect PLC program looks like?

Next article:The differences and similarities between high-frequency inverters and industrial frequency inverters

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- What are the functions of the Internet of Vehicles? What are the uses and benefits of the Internet of Vehicles?

- Power Inverter - A critical safety system for electric vehicles

- Analysis of the information security mechanism of AUTOSAR, the automotive embedded software framework

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- PlanAhead14.7

- Analog electronics elective test + DC and AC parameters

- Introduction to TI_DSP link command file (*.cmd)

- TI CC1310 sub1G SDK development unique identification number MAC address reading

- FPGA Implementation of ECT Image Reconstruction Algorithm

- Why does the AD21 shortcut key not work after modification?

- [ESP32-Audio-Kit Audio Development Board Review] Basic Use of the Development Board

- Can the SSTX and SSRX of USB3.0 be identified and adjusted? Is it necessary to cross it when making a schematic diagram?

- The battery output is DC3.0V after LDO. Why does it slowly rise from 0V to 3V when tested with an oscilloscope?

- Four advantages and applicable fields of LoRaWAN

ICCV2023 Paper Summary: Self-, Semi-, and Unsupervised Learning

ICCV2023 Paper Summary: Self-, Semi-, and Unsupervised Learning A Hitchhiker\'s Guide to Chip Verification - A Comprehensive View of Verification from System Theory to UVM

A Hitchhiker\'s Guide to Chip Verification - A Comprehensive View of Verification from System Theory to UVM Fast, Efficient and Predictabl

Fast, Efficient and Predictabl

京公网安备 11010802033920号

京公网安备 11010802033920号