Recently, the 11th EEVIA Annual China Hard Technology Media Forum and Industry Chain Research and Innovation Trend Outlook Seminar was grandly opened in Shenzhen.

Zhang Jing, product marketing manager of GigaDevice's innovative memory division, was invited to attend. With the theme of "Continuous Development, GigaDevice's New Generation of Storage Products Help Industry Innovation", she shared GigaDevice's extensive layout in the field of embedded memory and its orientation towards the industry. Innovative thinking on the wave of technological change, and jointly discuss the development trend of the memory market under the "semiconductor industry fluctuation cycle".

The pioneering path of GD Flash: 21.2 billion units shipped in 14 years

As we all know, Flash is a non-volatile memory. The stored content will not be lost in the event of power outage or power outage. It is an essential component for most electronic systems. As a company that starts with memory, GigaDevice launched China's first SPI NOR Flash in 2009. After years of product development and market expansion, the cumulative shipments of Flash products have exceeded 21.2 billion units, and the market share The rate has steadily increased.

"Ten years ago, the application scenarios of Flash were consumer products such as USB flash drives, DVDs, and LCD TVs; ten years later, automotive, industry, Internet of Things, 5G communications and other fields have become popular application scenarios for Flash." Zhang Jing said in her speech Said: "Following the pace of technological change, GigaDevice Innovation Flash continues to lead breakthroughs and now provides 27 product series, 16 product capacities, 4 voltage ranges, 7 temperature specifications and 29 packaging methods, covering It covers almost all application scenarios where code needs to be stored.”

GigaDevice’s innovative memory products displayed on site

So, how do developers choose the right Flash product? Zhang Jing interpreted Flash capacity, reading performance, packaging and other aspects from different applications.

In terms of capacity , depending on the application and system complexity, the Flash capacity required for storing code in different embedded systems varies greatly. For example, the Flash capacity required for consumer electronics is 512Kb~4Gb, while the Flash capacity required for IoT devices is 1Mb. ~256Mb. Currently, GigaDevice's innovative NOR Flash series provides capacities ranging from 512Kb to 2Gb, among which large-capacity SPI NOR Flash products of 512Mb, 1Gb, and 2Gb have filled the gap in domestic NOR Flash; the SLC NAND Flash series provides capacities ranging from 1Gb to 8Gb. Empowering consumer electronics, PC peripherals, network communications, automotive/industry and other fields to meet the demand for large-capacity data storage.

In terms of performance , GigaDevice GD25T/LT series is the industry’s first ultra-high performance, ultra-high reliability automotive-grade 4-port SPI NOR Flash product with a data throughput of up to 200MB/s and built-in ECC algorithm and CRC check function. , which can meet the stringent requirements of automotive applications. The GD25X/LX series has been further expanded. It is an 8-port SPI NOR Flash product with a data throughput of up to 400MB/s, achieving the industry’s highest level of product performance and enabling a wide range of automotive electronics applications.

In terms of packaging , GigaDevice is a leader in the storage industry. For example, in terms of 64Mb capacity, GigaDevice has launched the industry's ultra-small size 3 x 2 x 0.4 mm FO-USON8 packaging product, which is different from the traditional 3 x 2 mm USON8 The package is fully compatible, and the maximum supported capacity of the traditional 3 x 2 USON8 package is 32Mb. This means that developers do not need to modify the PCB, and can double the capacity by simply replacing a GigaDevice FO-USON8 packaged Flash. Not only that, in May this year GigaDevice launched the GD25LE128EXH chip in a 3 x 3 x 0.4 mm FO-USON8 package. This is currently the smallest plastic packaging product that the industry can achieve in 128Mb capacity. It is different from the traditional 3 x 4 mm USON8 The package is fully compatible, and the maximum supported capacity of the traditional 3 x 4 mm USON8 package is 64Mb. Developers do not need to change the PCB and can double the capacity by replacing it with the GD25LE128EXH chip, which can well meet the requirements of "light and thin" for wearable electronic products. , small” pursuit.

Explore the high energy efficiency application of advanced process SoC, 1.2V ultra-low voltage Flash contributes to green carbon

With the development of the dual-carbon concept, the application requirements for high energy efficiency and low power consumption have become increasingly prominent in the semiconductor field. At the same time, SoC main chips for mobile devices, cloud computing, automotive electronics, wearables and other applications are also moving towards advanced processes of 7nm and below; generally speaking, the more advanced the process node, the higher the SoC main chip performance and power consumption. The lower. At this time, the core power supply voltage of the SoC has also dropped to 1.2V. If conventional 1.8V NOR Flash is used, the peripheral circuit design will become complicated and the difficulty of product development will also increase.

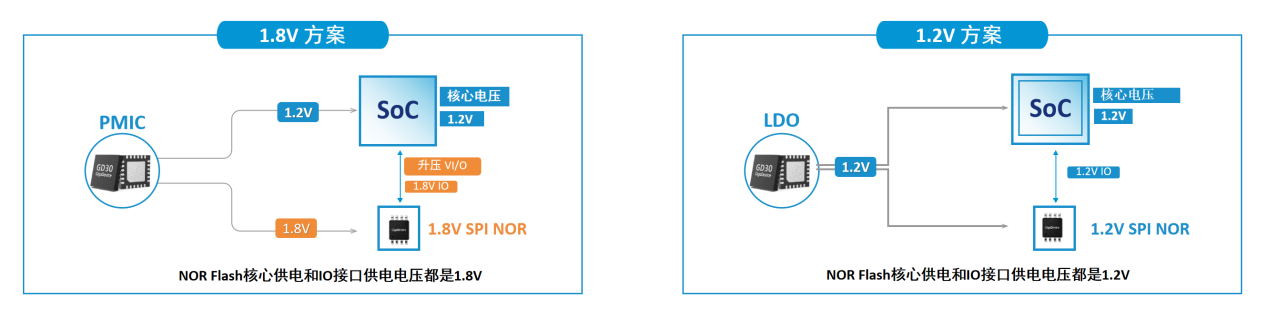

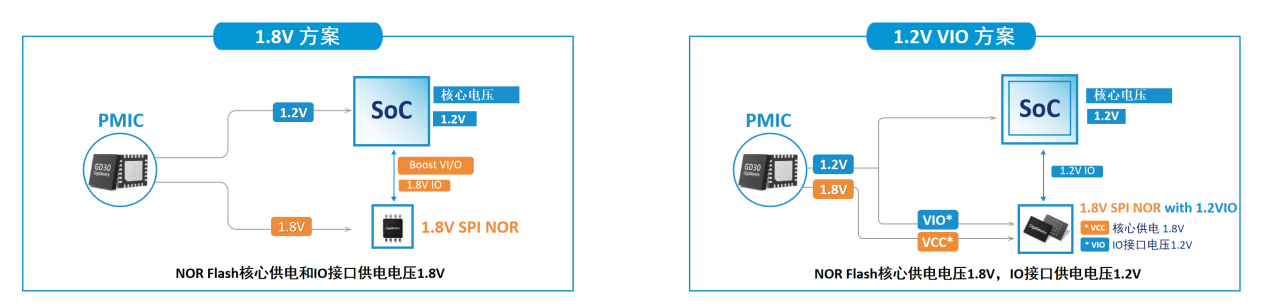

As shown in the figure below, the solution on the left is for a SoC with a core voltage of 1.2V to communicate with a 1.8V NOR Flash. The SoC design needs to add a boost circuit to increase the internal 1.2V voltage to 1.8V to match the 1.8 of the external NOR Flash. V voltage level, which obviously increases the complexity of the circuit design and increases the overall power consumption. The solution on the right is that the NOR Flash core power supply and IO interface power supply voltage are both 1.2V, which is consistent with the SoC core voltage of 1.2V. This can simplify the power supply design, eliminate the need for a boost circuit in the SoC, and reduce system power consumption.

In response to this trend, GigaDevice has launched the 1.2V SPI NOR Flash-GD25UF product series , which has reached the international leading level in key indicators such as data transmission speed and read and write power consumption under 1.2V operating voltage, and can be easily adapted An advanced process SoC with a core voltage of 1.2V. At the same time, compared with 1.8V NOR Flash, the power consumption of the 1.2V GD25UF series is reduced by 33% at the same current in Normal mode; in Low Power mode, the power consumption at the same frequency is reduced by 70%. These outstanding features make the GD25UF series a priority for next-generation wearable and mobile devices.

In addition, in response to the dual needs of high performance and low power consumption, GigaDevice has proposed a NOR Flash solution with a core power supply of 1.8V and an IO interface voltage of 1.2V - the GD25NF product series . This product provides a new solution for the circuit design of advanced process SoC: the IO interface voltage of Flash is 1.2V, and the SoC with core voltage of 1.2V does not need to add a boost circuit to communicate with it, simplifying SoC circuit design; the core power supply of Flash As 1.8V, it can maintain ultra-high reading and erasing performance, and overall, the read power consumption can be reduced by up to 40% compared to the conventional 1.8V solution. Therefore, this solution has also received widespread attention from integrators and OEMs. The GD25NF product series is currently in the sample delivery stage.

As a leader in embedded storage, GigaDevice not only focuses on key elements such as capacity, performance, packaging, and voltage, but also continues to focus on the critical reliability, security, and other aspects of memory, enabling the new generation of memory chips to meet The application needs of thousands of industries help industries accelerate innovation.

At the same time as the seminar, E-Dimension Think Tank's first "Annual Hard Technology Industry Awards" selection event and award ceremony were successfully held. GigaDevice Innovation GigaDevice won two trophies, the "China Technology Development Award" and the "'E' Ma Leading New Product Award" !

Previous article:Micron launches DDR5 memory based on 1β technology with a speed of up to 7,200MT/s

Next article:Micron’s low-power memory solutions help Qualcomm’s second-generation Snapdragon XR2 platform enhance mixed reality (MR) and virtual reality (VR) experiences

- Popular Resources

- Popular amplifiers

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- What are the functions of the Internet of Vehicles? What are the uses and benefits of the Internet of Vehicles?

- Power Inverter - A critical safety system for electric vehicles

- Analysis of the information security mechanism of AUTOSAR, the automotive embedded software framework

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- 【RT-Thread software package application works】Multi-function weather clock

- [Erha Image Recognition Artificial Intelligence Vision Sensor] 6. Identify motors and control their operation

- [N32L43x Review] DAC various waveform output tests

- ST60 millimeter wave water medium data transmission test report——part1

- 【GD32E503 Evaluation】 ADC Experiment (Continued)

- STM32 core Arduino board-ZeroKnow mini board with small size

- Programming examples to learn DSP timer and interrupt system

- TI Battery Tester Reference Design for High Current Applications

- [ESK32-360 Review] + TFT screen display function and expansion (1)

- [NXP Rapid IoT Review] Part 2: Detailed tutorial of online IDE - Open Rapid IoT to see the weather...

Monocular semantic map localization for autonomous vehicles

Monocular semantic map localization for autonomous vehicles ICCV2023 Paper Summary: Efficient and Scalable Vision

ICCV2023 Paper Summary: Efficient and Scalable Vision

京公网安备 11010802033920号

京公网安备 11010802033920号