In January 2019, after BorgWarner achieved mass production of the eDM electric drive module, it launched the fully integrated electric drive solution (iDM, integrated Drive Module) for pure electric drive and P4 hybrid.

BorgWarner’s iDM electric drive module is one of the key driving engines for the electrification of the automotive industry, fully demonstrating BorgWarner’s full range of strengths - the development of future solutions, close cooperation with global automakers and a deep understanding of customer needs.

Reducing emissions and providing cleaner mobility solutions are key challenges for OEMs and suppliers. BorgWarner’s compact, lightweight and efficient iDM products help electric vehicles reduce energy consumption and travel longer distances with the same battery . This advanced all-in-one electric drive system solution also has excellent NVH performance and can meet the cutting-edge electric vehicle and hybrid vehicle driveline requirements, helping OEMs design powerful, clean and efficient vehicles.

The iDM series has the excellent characteristics of high integration, high efficiency and light weight. It provides three models - iDM200 and iDM220, which can be easily integrated on the front or rear axle of passenger cars and light commercial vehicles according to the design architecture and different applications. In addition to pure electric vehicles , iDM is also suitable for P4 hybrid vehicles, that is, the motor is located on the rear axle of front-wheel drive vehicles.

The main advantage of the iDM series is its scalable and modular architecture, which supports a variety of gear ratios and motor sizes. The iDM operates at 220-480V DC (VDC), and can provide up to 160kW peak power and 3800N.m peak torque depending on the customer's vehicle voltage platform. This advanced electric drive product ensures smooth and quiet operation of the motor, while its hairpin flat wire stator winding motor technology provides excellent performance and excellent noise, vibration and harshness.

By 2025, BorgWarner's iDM electric drive system will also provide products with peak power of 300kW and peak torque of 4500N.m.

It is worth mentioning that all components used in the iDM module are mature technologies fully independently developed by BorgWarner, and can be used as highly integrated modules or independent new energy vehicle drive system solutions. In addition, the product supports various software function requirements of the vehicle platform and provides an advanced version controller that supports vehicle dynamics and energy management. Its software architecture meets current market demand and is easy to integrate into general platforms such as AUTOSAR, meeting ASIL D safety level requirements.

To meet the increasing demand for data exchange in modern vehicle systems, BorgWarner's advanced controllers can also be used with CAN, CAN FD buses and FlexRay.

The iDM electric drive system is mainly composed of eight modules: high-performance motor, transmission system cooling module, motor control module, signal connection interface, high-voltage power supply interface, drive shaft interface and parking lock system.

The core components of iDM - permanent magnet synchronous motor, high-performance electronic control module and efficient reduction mechanism are integrated together to minimize the layout space as much as possible, making it easier for vehicle manufacturers to arrange them on the vehicle.

BorgWarner iDM has three main modules:

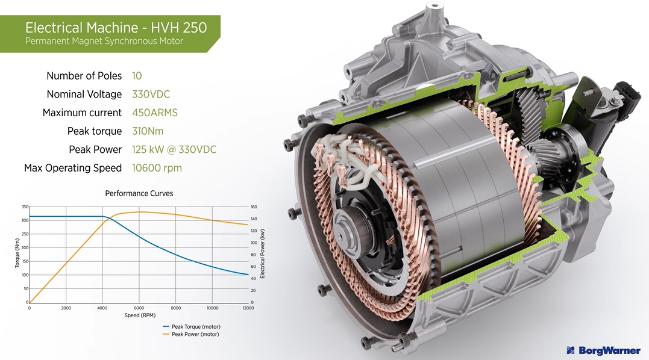

(1) High-speed motor: The motor in BorgWarner's iDM system is a permanent magnet synchronous motor with a maximum speed of 16,000 rpm. It can support a higher speed ratio to increase wheel-end torque output and reduce motor size. The motor also uses hairpin stator winding technology to significantly increase the power density of the motor.

With this patented technology, BorgWarner's high-speed motors have excellent performance in terms of noise, vibration and acoustic harshness. A German competitor just acquired a motor winding equipment supplier in early 2019 and began to absorb its winding equipment and key technologies. In this regard, BorgWarner is one step ahead and has mastered the core technology of high-efficiency motor manufacturing. In the future, motors will develop in the direction of smaller size and higher power density.

(2) Power electronics: Different from the mass-produced eDM products, the BorgWarner iDM eAxle system integrates an electronic control device. The BorgWarner iDM eAxle electronic control device currently uses the mainstream IGBT (Insulated Gate Bipolar Transistor) insulated gate bipolar transistor technology.

(3) Gear transmission mechanism: Whether a flexible reduction ratio can be provided to meet various customer needs is one of the key indicators for evaluating an electric drive system. BorgWarner's iDM system uses a fixed speed ratio and currently can provide customers with a reduction ratio of 12.5, which basically covers the power transmission needs of most customers for various models. From the market situation, BorgWarner's gear transmission ratio is higher than the average level.

New features of BorgWarner iDM

(1) Electronic vector control system: In order to ensure the stability of electric vehicles when passing through curves, BorgWarner has developed a coaxial motor with vector control. This system can control the torque output of the left and right axles at the same time, giving electric vehicles the electronic stability program (ESP) capabilities of fuel-powered vehicles . BorgWarner's current iDM integrates an open differential, which can easily achieve motor torque vector control. In order to prevent one side of the wheel from slipping (50% torque) and the other side from losing power (50% torque is not enough to drive the vehicle away), BorgWarner can also install an electronic differential lock, so that when one side of the wheel slips, the torque on the slipping side is set to zero, and the other side is given 100% torque, thereby driving the vehicle out of the slipping area.

(2) Electronic parking function: BorgWarner provides customers with an optional parking system. If the customer's vehicle is not equipped with an electronic parking brake system, they can choose to install an electronic parking system on the iDM drive system to ensure that the electric vehicle will not slip on a slope and save the cost of an electronic parking brake.

BorgWarner iDM software features

(1) BorgWarner's iDM supports various software functions and provides advanced versions that support vehicle dynamics and energy management. Its software architecture meets current market needs and is easy to integrate into general platforms such as AUTOSAR, and can achieve safety performance such as ASIL D.

(2) To meet the increasing demand for data exchange in modern vehicle systems, BorgWarner’s advanced power electronics can also be used in conjunction with the CAN or CAN FD bus.

Previous article:Improve fuel economy - Kia launches intelligent manual transmission

Next article:Brembo presents its latest brake technology and digital achievements at the Shanghai Auto Show

Recommended ReadingLatest update time:2024-11-16 13:56

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Comparison of 4G and 5G wireless technology details

- EEWORLD University Hall----MCU Peripheral Circuit_Lao Wu MCU Actual Combat

- Audio Circuit Debugging Tips

- [TI recommended course] #Industry's first professional RGB LED driver LP50xx demonstration #

- How to configure the background of Hikvision Ai equipment and thermal imaging equipment? What is the difference between them and ordinary network cameras? Please ask the experts! !

- How to get a multi-channel reference power supply

- TMS320F28335GPIO Example - Light up the LED

- Analysis of 2020 E-sports Contest C: The realization process of the 99-point ramp car

- MSP430F4152 development board schematic diagram

- #Power supply roadblock#Experience sharing summary

Digilent Vivado library

Digilent Vivado library EMC test standard: CISPR 25 standard

EMC test standard: CISPR 25 standard

京公网安备 11010802033920号

京公网安备 11010802033920号