In early July, at the high-level seminar on new energy vehicles held by China Automotive Research Institute, experts from various fields gathered to discuss the development dilemma and development plan of the domestic new energy vehicle industry. In particular, the latecomers have opened up another path, combining driverless and electric vehicles for research and development. Traditional car companies should be more vigilant, integrate resources, focus on the research and development of power batteries, fundamentally break through the bottleneck, and achieve overtaking on the curve. First, let's understand the current status and trends of new energy vehicle technology development at home and abroad. The following is a live speech from Hou Fushen, deputy secretary-general of the China Society of Automotive Engineers.

Hou Fushen, Deputy Secretary General of SAE-China

Hou Fushen, Deputy Secretary General of SAE-China

In 2011, the annual sales volume of new energy vehicles in the world was 50,000 units, and last year it was close to 600,000 units. The total number of vehicles in use is estimated to exceed 1.3 million units, entering a stage of large-scale industrialization. The momentum continued in the first half of this year. From January to May, the global sales volume of new energy vehicles reached 234,000 units, a year-on-year increase of nearly 70%.

From a national perspective, we had an exciting landmark development last year, which was to surpass the United States to become the world's largest producer and seller of new energy vehicles. Last year, our production and sales volume was nearly 380,000 vehicles, accounting for about 64% of the global total. More than 60% of the world's new energy vehicles are in our country. In terms of industry scale and marketization process, we are indeed a leader, but there is still a big gap in technology.

Global New Energy Vehicle Development Overview and Overall Trends

From a national perspective, the United States has developed relatively steadily in recent years, with sales of new energy vehicles basically reaching 100,000 units per year. Japan's current sales volume is not particularly large, and there was a significant decline last year. We analyzed that this was mainly due to the impact of oil prices. In addition, Japan's ordinary hybrid vehicles have developed very quickly, but in fact, their total volume is limited. This may have affected the development of pure electric vehicles to some extent. In Europe, countries like France and the United Kingdom are still developing relatively fast, with growth of 40 to 50 percent.

From the perspective of vehicle models , according to our country's definition, new energy vehicles are mainly pure electric, plug-in hybrid, and fuel cell vehicles. At present, the main focus is on pure electric and plug-in hybrid, especially pure electric vehicles, which have the largest volume. Fuel cell vehicles are currently in the early stages of industrialization, that is, the market introduction stage of products. The main sales are in Japan and the United States, and in fact, they are mainly Toyota's sales. Last year, the market size was about 500 vehicles.

Among the major best-selling models , pure electric ones still account for the majority, with 12 models, especially Tesla, which is still the global sales champion. China also has nine models in the top 20 best-selling models in the world, and is indeed in a leading position in terms of marketization.

In terms of the overall technological trend, there are two aspects to new energy vehicles. One is the technological development of new energy itself. Everyone is very clear about this major trend. The focus is still on power batteries , how to increase energy density, how to increase driving range, including reducing costs. However, we also look at the trend of the entire automotive industry from another perspective, which is also a major trend in the development of new energy vehicles. I think there are three main aspects : lightweight, intelligent, and low-carbon .

轻量化:每减重1%,带来的节能效果还是非常显著的。特别是对新能源汽车来讲,因为现在电池的能量密度还比较低,整个车重还是比较重,对新能源汽车来讲更需要轻量化。与此同时,轻量化带来的不光是技术上的进步和革新,更重要的是它会带来一些对我们传统制造加工工艺,包括生产模式的重大变革。

For example, the BMW i3 uses carbon fiber materials on a large scale. The weight of the whole vehicle is now only 1,195 kg, which is 250-350 kg lighter than traditional vehicles. The weight reduction effect is very obvious. Moreover, the weight of its body is only 180 kg, and the utilization rate of the entire composite material reaches 50%.

Therefore, carbon fiber, a new lightweight material, may be popularized and applied first in electric vehicles in the future. In addition, Tesla has also done a lot of work on the use of aluminum alloy materials.

Intelligence : It has been very popular in the past two years. To some extent, I feel that it is more popular than new energy. Whether it is traditional cars or the combination with electric cars, it is a new development hotspot. For electric cars, there are more application advantages because the level of electronic control is relatively high. According to the development prospects of international consensus, Japan and Europe currently estimate that fully automatic driving will be achieved in the stage of 2025-2030, which is about ten years. I think this is also an important direction that everyone needs to pay attention to.

Low carbonization : Low carbonization here is actually a concept of the entire biological cycle. There are still different voices in society about the development of electric vehicles. There are doubts about whether electric vehicles can reduce emissions. This is mainly because of the structure of electricity, with coal-fired power accounting for nearly 70%. If the energy consumption of electric vehicles cannot be controlled at a reasonable level, there will indeed be a situation where emissions will not be reduced. From a future perspective, renewable energy must be introduced to truly achieve low emissions and zero emissions in the biological cycle. This is not only what we are concerned about, but the international community has also invested a lot of energy in this area in recent years. In particular, Europe, the United States, and Japan have done a lot of experimental verification work in this regard, actively promoting the integration of new energy vehicles and renewable energy. This is also an important development direction for us in the future.

A very important link is that if new energy vehicles and renewable energy, including the integration of smart grids, not only solve the problem of environmental benefits, but more importantly, it can also bring economic benefits, especially the cascade utilization of batteries. If the cascade utilization of power batteries can be achieved, it will play a very important role in reducing the cost of new energy vehicles and promoting their rapid popularization.

Domestic New Energy Vehicle Technology Progress

In terms of vehicle types, we are still mainly focusing on pure electric vehicles. Among pure electric vehicles, the number of commercial vehicles and passenger vehicles is equal, which is also what makes us different from foreign countries. Globally, foreign countries still focus on passenger vehicles. We also did some statistics on the top 10 sales in the market last year. The current sales champion is still plug-in vehicles, and BYD Qin has a relatively large volume. Among the top 10 models, there are 7 pure electric models and 3 plug-in models.

Specifically, let's look at the progress of technology. For pure electric passenger cars, the development of a dedicated electrified chassis with a completely new structure that adapts to the characteristics of electric vehicles, including the development of a completely new structure of the vehicle, is a very important sign. Because in the early stage, most of them were modified vehicles, which were modified on the basis of the original fuel vehicles, so many performances could not be optimized.

Compared with international standards, we believe that the domestic technology level is two to three years behind that of foreign products, which is a gap of half a generation of products.

From the perspective of energy consumption and power performance , these are explicit indicators. Nissan's LEAF is a representative model. This car weighs nearly 1.5 tons, and its energy consumption is at the level of 11.4 degrees per 100 kilometers. Looking at some of our current products, there are still deficiencies in energy consumption. For example, SAIC's 150 is nearly 400 kilograms lighter than others, but its power consumption is slightly higher than others. This shows that the optimization of the overall performance in China and the low energy consumption still need to be worked on. Therefore, the current new energy vehicle subsidy policy is also brewing. In addition to the requirements for the driving range of pure electric passenger cars, some requirements for energy consumption should be added.

In terms of power , there is a big gap between our acceleration time and that of foreign countries. These two indicators are visible to everyone, explicit indicators. In fact, some internal indicators, including our reliability, and the quality of vehicle control, comfort and other aspects of performance, are invisible to us, but these are the areas where we have the biggest gap.

In terms of new energy buses , we are still in a leading position in technology, with the largest market application scale in the world. This field is also the most innovative, with various technical solutions emerging one after another and being put into practical use on a large scale in various places.

Various solutions are summarized here. There are several main technical solutions, including long driving range, slow charging solutions, short driving range, fast charging solutions, such as lithium titanate solutions, battery swap solutions, online charging, solutions using supercapacitors, extended range solutions, and plug-in hybrid solutions. Localities can make targeted choices based on their actual conditions. From the perspective of economy, these solutions are relatively expensive, such as long driving range, slow charging solutions, and battery swap solutions. When choosing, you should make an in-depth analysis of the economy.

Here are some parts information. At present, from the perspective of motors, we have basically covered the demand for motor power for new energy vehicles below 200 kilowatts. The power density and efficiency of the drive motors are basically comparable to the international level, and the peak power is mostly 2.8-3000 watts/kilogram. We are also developing high-speed motors, which have also been put into use. The highest speed can now reach 12,000 revolutions.

The progress of batteries is quite obvious. Lithium iron phosphate batteries have been widely used, and the energy density has increased from 90 watt-hours/kilogram in 2007 to 140 watt-hours/kilogram at present. Ternary materials have been paid attention to in recent years and have begun to be put into vehicles in batches. The energy density can reach 180 watt-hours/kilogram, which is basically in line with the international monomer level.

The system price of batteries has dropped from 5 yuan/watt-hour in 2007 to 3 yuan/watt-hour. The power-type battery has a maximum specific power of 3,000 watts/kilogram. In addition, lithium titanate batteries have also solved a series of technical problems such as flatulence and have been put into practical use.

In terms of vehicle control and integration , the backbone vehicle companies now have the development system and development capabilities, especially from the system to the software and hardware levels. In particular, in the software and hardware development model, they are also compatible with the world's most advanced systems and have basically mastered the integrated control and evaluation technology of pure electric vehicles.

We have also developed corresponding products in the areas of chargers and electric air conditioners . In particular, air conditioners are well known to everyone. Air conditioning cooling and heating have a great impact on the energy consumption of electric vehicles and their driving range. We are currently mainly using the CTV method for heating. However, in recent years, we have also been promoting the development of efficient heat pump air conditioning technology from the perspective of the society. At present, our prototype has also been released, and the focus of the next two years will be on solving the problem of industrialization.

In terms of braking, we have also made a series of progress, including the electric power steering system, which can be said to have been commercialized.

In terms of fuel cells , we are still in the stage of technology research and development. According to our judgment, the gap between us and foreign countries is widening, especially from the perspective of the industrial chain. Foreign complete vehicles have played a very important role in the development of fuel cells. The industrial chain and research and development system of key components, including materials, are very complete. Our country is seriously lacking in the industrial chain. Many key components cannot be solved. After so many years of research, they cannot be solved and still need to rely on foreign imports.

Development Status of Domestic New Energy Vehicle Technology——Gap Analysis

At present, our technology can achieve a cold start at -20 degrees Celsius, but the level abroad is above -30 degrees Celsius. Our life span is 3,000 hours, while that abroad is at least 5,000 hours. We have now reached 2,000 watts per liter in terms of power density, 1,000 watts per watt per liter, and 60% in terms of energy efficiency. In particular, the amount of platinum used is 0.6 grams per kilowatt. For us, the reduction is still relatively large, but compared with the international level, we still have a big gap. Two days ago, I held an IEA fuel cell protocol working group meeting in Spain. Now Japan has achieved a level of 0.2 grams per kilowatt, and the future goal is 0.1 grams per kilowatt. Therefore, the reduction in the amount of platinum has a direct impact on the reduction in fuel cell costs.

From the perspective of complete vehicles, we have started to develop from cars to buses and have also conducted small-scale tests. However, the participation of complete vehicle companies is not high at present, and the investment in this area is seriously insufficient. Compared with foreign cars and buses, our cars and buses lag behind in all aspects in terms of vehicle efficiency, driving range, cost, durability, hydrogen refueling time, low-temperature starting performance, etc., which really needs the industry to pay attention to.

In terms of pure electric and plug-in vehicles, we lag behind foreign countries mainly in key core technologies. For example, in terms of pure electric vehicles, we are still lacking in mass production processes, quality control and reliability. In terms of cost control, we still need to further improve.

When it comes to plug-in hybrid vehicles, we have more technical difficulties because they are relatively complex. They include hybrid-specific engines, range extenders, electromechanical coupling devices, motor systems, etc. The gaps in these key components are also relatively large.

As for the motor and power electronics assembly, the motor speed and controller power density still need to be improved, and the integration of power electronics is not yet high. The battery and management system also involve consistency and reliability issues, including integration issues. In terms of vehicle electronic control, we have not accumulated enough experience in the entire verification, testing, and calibration, and we still have a lot of technical work to do.

In terms of fuel cells, the power of our generators for cars is significantly lower than the international level. The most fundamental reason is that our power density is relatively low now.

In terms of durability, our assessment is not sufficient. For example, the durability of buses is only 3,000 hours, while foreign countries have achieved a level of more than 10,000 hours.

Domestic new energy vehicle technology development trend

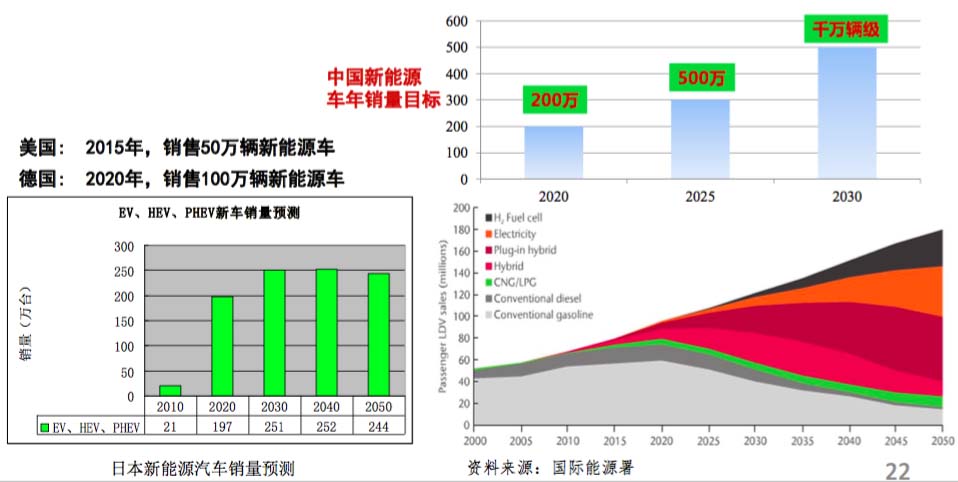

From the perspective of development trends, this chart is quite shocking. This is the forecast of the International Energy Agency (IEA) . Starting from 2020, the market share of traditional gasoline and diesel vehicles will begin to decline. New energy vehicles, including ordinary hybrid vehicles, will continue to expand their market share in the future.

The table in the upper right corner is the forecast and judgment formed by our technology roadmap research team about the future. The annual sales target of China's new energy vehicles is expected to be 2 million vehicles in 2020, 5 million vehicles by 2025, and 10 million vehicles by 2030.

This is the technical development goal and path in stages. From the perspective of the whole vehicle, the main work is to reduce weight, reduce energy consumption, and increase driving range. This is the main line. For plug-in hybrid vehicles, the most important thing is to reduce fuel consumption, which is different from the fuel consumption mentioned before. The previous assumptions were all comprehensive fuel consumption, which converted electricity consumption and fuel consumption together. Now it is proposed that the next step is to focus on assessing the fuel consumption in hybrid mode. To truly test the technical level of the hybrid system of plug-in hybrid vehicles, we have put forward some requirements for fuel consumption indicators accordingly.

For motors, we still need to improve the power density and torque density, and for motor controllers, we need to improve the power density.

For batteries, we have a special task force on the technical roadmap of batteries. Our current goal is to achieve a single cell specific energy of 300 Wh/kg by 2020, 400 Wh/kg by 2025, and 500 Wh/kg by 2030. Our current best level is 180 Wh/kg, and we need to reach 300 Wh/kg by 2020, which is a huge challenge.

As for the cost , the cost of a single cell should be reduced to 1 yuan/Wh by 2020, and the cost of the system should be reduced to 1.3 yuan/Wh. In 2025, the cost of a single cell should be reduced to 0.8 yuan/Wh, and the cost of the system should be reduced to 1 yuan/Wh. By 2030, the cost of a single cell should be reduced to 0.6 yuan/Wh, and the cost of the system should be reduced to 0.8 yuan/Wh. The cost should be gradually reduced.

In addition to fuel cells, hydrogen energy is also a key link. By 2030, the technical solutions of large-scale centralized hydrogen production and distributed hydrogen production will basically be adopted. Before 2025, large-scale centralized hydrogen production will mainly use coking coal gas and exhaust gas as the technical solutions for hydrogen production, and after 2025, large-scale coal hydrogen production will be used. For distributed hydrogen production, more distributed hydrogen production using renewable energy will be gradually introduced.

For the goal of fuel cell vehicles, the power level of the engine still needs to be improved, and both sedans and buses will be gradually improved.

寿命方面,要从目前轿车和客车分别3000小时、5000小时要提高到5000-10000小时(2020年)。成本要有显著的下降。

The work that needs to be done in the field of fuel cells, from materials, components, engines, power systems to complete vehicles, utilization of hydrogen energy, including large-scale demonstrations, all need to be advanced in a complete, comprehensive and systematic manner.

Previous article:Decoding Dedicated Short Range Communication (DSRC), the foundation of autonomous driving is here!

Next article:Audi's new technology: Let cars understand traffic lights

- Popular Resources

- Popular amplifiers

- GigaDevice's full range of automotive-grade SPI NOR Flash GD25/55 wins ISO 26262 ASIL D functional safety certification

- Breaking through the intelligent competition, Changan Automobile opens the "God's perspective"

- The world's first fully digital chassis, looking forward to the debut of the U7 PHEV and EV versions

- Design of automotive LIN communication simulator based on Renesas MCU

- When will solid-state batteries become popular?

- Adding solid-state batteries, CATL wants to continue to be the "King of Ning"

- The agency predicts that my country's public electric vehicle charging piles will reach 3.6 million this year, accounting for nearly 70% of the world

- U.S. senators urge NHTSA to issue new vehicle safety rules

- Giants step up investment, accelerating the application of solid-state batteries

- Intel promotes AI with multi-dimensional efforts in technology, application, and ecology

- ChinaJoy Qualcomm Snapdragon Theme Pavilion takes you to experience the new changes in digital entertainment in the 5G era

- Infineon's latest generation IGBT technology platform enables precise control of speed and position

- Two test methods for LED lighting life

- Don't Let Lightning Induced Surges Scare You

- Application of brushless motor controller ML4425/4426

- Easy identification of LED power supply quality

- World's first integrated photovoltaic solar system completed in Israel

- Sliding window mean filter for avr microcontroller AD conversion

- What does call mean in the detailed explanation of ABB robot programming instructions?

- USB Type-C® and USB Power Delivery: Designed for extended power range and battery-powered systems

- RAQ #223: How to measure and determine soft-start timing without a soft-start equation?

- RAQ #223: How to measure and determine soft-start timing without a soft-start equation?

- GigaDevice's full range of automotive-grade SPI NOR Flash GD25/55 wins ISO 26262 ASIL D functional safety certification

- GigaDevice's full range of automotive-grade SPI NOR Flash GD25/55 wins ISO 26262 ASIL D functional safety certification

- New IsoVu™ Isolated Current Probes: Bringing a New Dimension to Current Measurements

- New IsoVu™ Isolated Current Probes: Bringing a New Dimension to Current Measurements

- Infineon Technologies Launches ModusToolbox™ Motor Kit to Simplify Motor Control Development

- Infineon Technologies Launches ModusToolbox™ Motor Kit to Simplify Motor Control Development

- STMicroelectronics IO-Link Actuator Board Brings Turnkey Reference Design to Industrial Monitoring and Equipment Manufacturers

- Can a bandpass filter be powered from a single supply?

- Yulin Dog Meat Festival opens, streets and alleys are covered with "boycott" posters

- Discussion on Graphical Programming Method of Single Chip Microcomputer

- Op amp problem

- MSP430 MCU Basics

- Evaluation Invitation Ticket Record Form

- How does a MCU software engineer write simple computer software?

- GD32F350 Bluetooth upright car DIY video demonstration

- Smart IoT Student Dormitory Based on RSL10

- my country's first beauty robot debuts, speaks English and Sichuan dialect

NVD

NVD

京公网安备 11010802033920号

京公网安备 11010802033920号