Traditional ward call systems are generally wired, which not only requires cumbersome wiring and installation, inconvenient maintenance, low utilization rate, but also poor real-time performance. Although the wireless call system has no wiring problems, its reliability is poor, and radio waves can interfere with other medical equipment. Most hospitals currently do not use wireless call systems.

With the development of power carrier technology, it has become possible to use low-voltage power lines as transmission media and use technologies such as spread spectrum, digital coding, and microcontroller control to realize ward calls. This article uses power carrier technology to design a ward call system.

1 Basic requirements for ward call system

Clinical help call is an important means of transmitting clinical information. The ward call system is an emergency call tool for patients to request the doctor or nurse on duty for diagnosis or care. It can quickly transmit the patient's request to the doctor or nurse on duty and monitor it in the monitoring center in the duty room. Leaving accurate and complete records on the computer is one of the necessary equipment to improve the level of care in hospitals and wards. The quality of the call system is directly related to the safety of patients, and has always been generally valued by major hospitals. It requires timely, accurate, reliable, simple and feasible, and conducive to promotion. The hospital bed call system, designed using power line carrier communication technology, single-chip multi-machine communication and computer monitoring and management technology, has functions such as calling, ringing, display queuing, priority setting, storage and recording, etc., which meets the hospital's ward management and nursing requirements.

2 Ward call system design

2.1 System composition and working principle

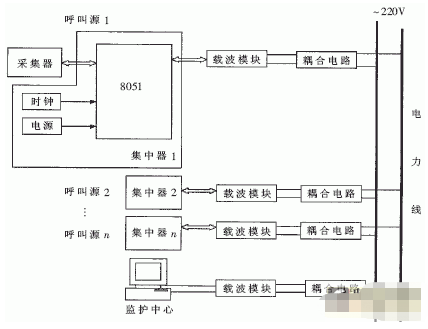

The ward call system consists of several call sources (generally one for each hospital bed), modem carrier module, coupling circuit and monitoring system, as shown in Figure 1. When there is a call signal from the call source, there will be corresponding sound and light call signal indications on the monitoring system, and the call number can be displayed. If the parallel bus expansion method is used, the wiring between hundreds of call sources and the host is too complicated. Therefore, this system uses the serial communication function of the microcontroller to allow the signals between the host and each slave to pass through the power line carrier modulation and demodulation module. Through ~220V civil power line transmission, two-way data transmission between the host and the slave is realized.

Figure 1 System block diagram

The system adopts a master-slave structure. The monitoring system (host) is placed in the doctor's duty room (it can be connected to the computer through an interface circuit to form a monitoring center). When there is a call request from the hospital bed, it will give an audible and visual alarm and display the position of the hospital bed on the monitor. . The call source (slave machine) is placed in the ward. When the patient has a call request, press the request button to call the duty room and light up the call indicator light. The master and slaves are connected together through power lines. When the master and the slave communicate, the master sends address information to each slave in turn. Each slave receives the address information sent by the master. If it is the same as its own address, it sends its own alarm information to the master. If there is no alarm information, it sends its own alarm information to the master. The host sends a null number (00).

2.2 Introduction to SC1128 spread spectrum communication chip and transceiver circuit

The SC1128 chip is a dedicated spread spectrum modulator/demodulator circuit developed for the power line carrier communication market. Due to the adoption of new technologies such as direct sequence spread spectrum, digital signal processing, and direct digital frequency synthesis, this circuit has strong anti-interference and anti-attenuation performance in power line communications. The SC1128 chip integrates spread spectrum/despreading, modulation/demodulation, D/A conversion and A/D conversion, built-in electronic meter, output driver, input signal amplification, watchdog, working voltage detection and communication with the microcontroller (MCU). Serial communication and other functions. This chip can reduce system costs and improve system functions in small multi-functional application systems.

The block diagram of the transceiver circuit composed of the SC1128 chip is shown in Figure 2. The signal enters the SC1128 chip from the power line through the coupler, bandpass filter and preamplifier. After processing, it is sent to the power line through the power amplifier and coupler to complete the transmission and reception of the signal on the power line. Box one is a coupling coil, which can couple the signal transmitted in box three to the power line; it can also couple the signal received on the power line to box two. Box 2 is the front-end receiving circuit. After filtering and amplifying the received signal, it is sent to the first-level operational amplifier (pin 13) of SC1128 for processing. Box 3 is the power amplifier, which amplifies the phase modulation signal sent by pin 24 of SC1128 and sends it to the power line through the coupling coil. Box 4 is part of the analog signal processing circuit inside SC1128, including a three-stage operational amplifier, one of which has an adjustable gain.

Figure 2 Transceiver circuit block diagram composed of SC1128 chip

2.3 Design of call source circuit

The call source consists of 8051 microcontroller (slave machine), SC1128 spread spectrum communication chip and some peripheral circuits, as shown in Figure 3. Eight request button switches are connected to the P0 port of the microcontroller 8051. When a certain button is pressed, a certain input status of the P0 port corresponding to the button is 0. When the microcontroller confirms that the host calls the machine's address, it scans the 8-bit I/O port status on the P0 port. Once a key is pressed, it immediately sends the request information corresponding to the P0 port to the host and waits for the host's confirmation. When the host returns correct information, the corresponding LED indicator light is driven through the P2 port to indicate which request signal was sent successfully. The eight request button switches are numbered respectively. Each switch represents a type of request information and is defined by the user.

Figure 3 Ward call source circuit

The P1.0 and RST/VPD ports of the 8051 microcontroller are connected to the backup power supply and power-down protection circuit to ensure that the system can be used normally when a power failure such as a power outage occurs. If the system has detected the "power-down failure is about to occur" signal, the signal requests an interrupt to the host through the external interrupt INT0. The host responds to the interrupt and sends the relevant data to the internal RAM for storage, and then writes "0" to P1.0, which is A low level on the .0 pin triggers the 555 timer, and the output pulse of the 555 timer depends on R, C, and VCC. If the 555 timer expires and VCC is still normal, this indicates that the "power down failure is about to occur" signal is a wrong alarm signal, then the positive pulse output by the 555 is added to the RST/VPD to reset the host and start operating again; if the RST/VPD When the 555 timer does become low at the end of the timer, the 555 timer outputs a high level when triggered by the low level of P1.0 and adds it to RST/VPD as a backup power supply until VCC returns to normal, and then maintains a period of R, The positive pulse width time determined by C. Appropriate R and C values should be selected so that there is sufficient power-on reset time after the main power supply VCC returns to normal, so that the host can reliably reset and resume normal operation. The clock of 8051 adopts on-chip clock oscillation mode, and the XTAL1 and XTAL2 pins are externally connected to a quartz crystal (6MHz) and oscillation capacitor. The serial ports RXD (P3.0) and TXD (P3.1) communicate with the host through the SC1128 chip and power lines. The call source interrupt program flow chart is shown in Figure 4.

Figure 4 Call source interrupt program flow chart

2.4 Monitoring system design

The monitoring system consists of 8051 microcontroller (host), display device, alarm circuit, SC1128 chip and some peripheral circuits, as shown in Figure 5. The three I/O lines of the P0 port of the 8051 microcontroller provide the clock signal, enable signal and serial data required by the MC14499. The MC14499 drives and controls four LED eight-segment displays. The LED digital tube displays the bed number of the patient who issued the alarm. and alarm category. The first three LEDs indicate the bed number, and the last three LEDs indicate the alarm category.

The P2.0 port drives the alarm speaker through the NOT gate. The host computer is equipped with a button key K, which is directly connected to INT0. K is used to cancel the alarm sound and the alarm source indicated by the LED digital tube. The backup power supply, power-down protection circuit and clock oscillation method used in this circuit are the same as those of the call source circuit. The program flow chart of the monitoring system is shown in Figure 6.

Figure 5 Monitoring system

Figure 6 Monitoring system program flow chart

2.5 Ward call management system software design

The above circuit combination can complete the ward call function. In order to improve the system and enable the call system to be combined with bed information management, the ward call management system software is designed to form a ward monitoring center composed of computers and corresponding interface circuits. . The call information is processed by the microprocessor and input to the computer through the interface circuit, and then the call information and patient information are managed through computer software. Here we only introduce the ward call management system software based on POWER BUIDER9.0 as follows: This system has a protection function. Non-administrators cannot enter the system to obtain information. Only by obtaining a password can they enter the information interface of the system. The login interface is shown in Figure 7.

Previous article:USB-Controller Area Network (CAN) conversion of CP2102 and C8051

Next article:Generating 3-wire signals using multiple DS1267 digital potentiometers and an 8051 microprocessor

Recommended ReadingLatest update time:2024-11-22 04:55

- Popular Resources

- Popular amplifiers

-

MCU C language programming and Proteus simulation technology (Xu Aijun)

MCU C language programming and Proteus simulation technology (Xu Aijun) -

Principles and Applications of Single Chip Microcomputers 3rd Edition (Zhang Yigang)

Principles and Applications of Single Chip Microcomputers 3rd Edition (Zhang Yigang) -

Principles and Applications of Single Chip Microcomputers and C51 Programming (3rd Edition) (Xie Weicheng, Yang Jiaguo)

Principles and Applications of Single Chip Microcomputers and C51 Programming (3rd Edition) (Xie Weicheng, Yang Jiaguo) -

STC32G Series MCU Technical Reference Manual

STC32G Series MCU Technical Reference Manual

- Naxin Micro and Xinxian jointly launched the NS800RT series of real-time control MCUs

- How to learn embedded systems based on ARM platform

- Summary of jffs2_scan_eraseblock issues

- Application of SPCOMM Control in Serial Communication of Delphi7.0

- Using TComm component to realize serial communication in Delphi environment

- Bar chart code for embedded development practices

- Embedded Development Learning (10)

- Embedded Development Learning (8)

- Embedded Development Learning (6)

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Intel promotes AI with multi-dimensional efforts in technology, application, and ecology

- ChinaJoy Qualcomm Snapdragon Theme Pavilion takes you to experience the new changes in digital entertainment in the 5G era

- Infineon's latest generation IGBT technology platform enables precise control of speed and position

- Two test methods for LED lighting life

- Don't Let Lightning Induced Surges Scare You

- Application of brushless motor controller ML4425/4426

- Easy identification of LED power supply quality

- World's first integrated photovoltaic solar system completed in Israel

- Sliding window mean filter for avr microcontroller AD conversion

- What does call mean in the detailed explanation of ABB robot programming instructions?

- Europe's three largest chip giants re-examine their supply chains

- Breaking through the intelligent competition, Changan Automobile opens the "God's perspective"

- The world's first fully digital chassis, looking forward to the debut of the U7 PHEV and EV versions

- Design of automotive LIN communication simulator based on Renesas MCU

- When will solid-state batteries become popular?

- Adding solid-state batteries, CATL wants to continue to be the "King of Ning"

- The agency predicts that my country's public electric vehicle charging piles will reach 3.6 million this year, accounting for nearly 70% of the world

- U.S. senators urge NHTSA to issue new vehicle safety rules

- Giants step up investment, accelerating the application of solid-state batteries

- Guangzhou Auto Show: End-to-end competition accelerates, autonomous driving fully impacts luxury...

- TI Industrial Month Q3 - A sneak peek at reference design highlights

- 3G should allow the fourth voice to emerge

- How to connect WiFi protocol smart lights to Mijia

- Python Tinker Study Notes (Part 1)

- Surplus of satellite transponders over China

- Busy and fulfilling dry cold

- 【ST NUCLEO-G071RB Review】First Look at NUCLEO-G071RB

- Energia upgraded to 1.8.7E21

- [NXP Rapid IoT Review] Detailed operation process from unboxing to cloud programming

- PT2314.pdf

MCU C language programming and Proteus simulation technology (Xu Aijun)

MCU C language programming and Proteus simulation technology (Xu Aijun)

京公网安备 11010802033920号

京公网安备 11010802033920号