With the continuous development of computer technology and communication technology, the Internet and embedded intelligent instruments are increasingly widely used. Its emergence provides strong technical support for distributed control systems to achieve real-time and reliable data communication between nodes. It is a serial communication network that effectively supports distributed control or real-time control. This paper analyzes the design of an intelligent anti-electricity theft system based on LPC2132.

1 Overall hardware design plan

Based on the above functional planning of the device, the device design can be planned into two parts. The intelligent monitoring system consists of a host computer and a slave computer. The host computer is implemented by a PC. The slave computer includes a main control microcontroller composed of MSP430F149, a 4×4 human-machine interface keyboard, a relay control circuit, and an acoustic and optical alarm circuit.

1.1 Sensor selection

1.1.1 Electricity metering chip selection

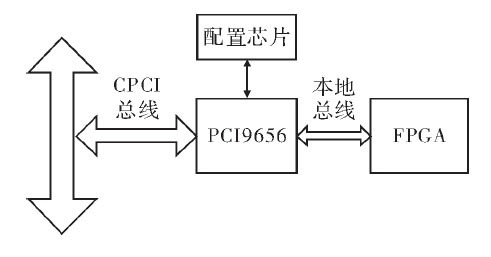

The electricity collection part mainly uses the electric energy metering chip AD7755 to collect and store electricity. A day can be divided into 48 time periods, that is, one time period every half an hour. The microcontroller sends the number of pulses collected within half an hour and the maximum power value collected within half an hour to the database server, and then the database server implements real-time data update and publishes it in the form of a dynamic web page. The power sampling circuit is the key circuit for power metering, as shown in Figure 1.

Figure 1 Power sampling circuit

1.1.2 Selection of oil temperature sensor

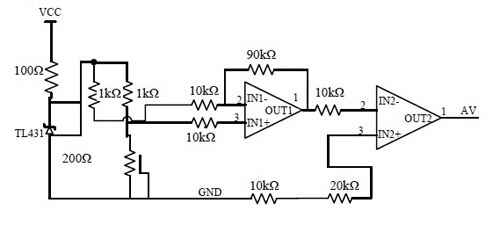

A platinum resistor is used as the sensor for measuring transformer oil temperature, and its temperature measurement circuit is shown in Figure 2. The oil temperature sensor is used to measure the oil temperature of the transformer. When the oil temperature is higher than the set value, an alarm is triggered and the transformer switch is cut off.

Figure 2 Temperature measurement circuit

Its parameters are as follows:

① Measuring range: -200℃~+850℃; ② Allowable deviation value △℃: Class A ±(0.15+0.002│t│), Class B ±(0.30+0.005│t│); ③ Minimum insertion depth: The minimum insertion depth of the thermal resistor ≥200 mm; ④ Allowable current ≤5 mA.

1.1.3 Selection of oil level sensor

UZF2 (side-mounted) remote transmission column control level gauge is selected. The magnetic column level gauge is a device specially developed for liquid level measurement based on the principles of magnetism, Archimedes (law of buoyancy) and other principles, which is cleverly combined with the characteristics of mechanical transmission. The control type adds a magnetic switch to the column level gauge. While monitoring the liquid level, the magnetic switch signal can be used to control or alarm the liquid level; the remote transmission type adds a 4~20mA transmitter sensor to the column level gauge. While monitoring the liquid level on site, the change of the liquid level is transmitted to the control room through the transmitter sensor, cables and instruments to achieve remote monitoring and control.

1.1.4 Selection of anti-electricity theft signal

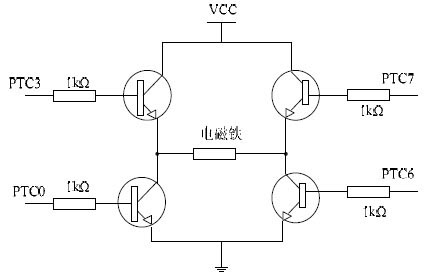

After the whole system is powered on, the main control system and microcontroller start self-test. After initialization, if no command is received from the remote management center via GPRS, the main measurement and control system sequentially reads the current and monitoring data of the meter, measures the oil temperature and oil level of the transformer and processes the data, determines whether the meter box door is normal, receives the measurement and monitoring data sent by the measurement and control subsystem at regular intervals, and processes the data and outputs the control. At the same time, the measurement and control subsystem sequentially measures the current and the oil temperature in the high-voltage magnetic sleeve, and monitors the state and oil level of the positioning electromagnet in the high-voltage magnetic sleeve. When the main measurement and control system receives the command sent by the remote management center via GPRS, it determines whether the command is a closing or disconnecting command for the load switch inside the transformer, or a positioning or release command for the positioning electromagnet in the magnetic sleeve and a positioning or release command for the positioning electromagnet in the meter box door. The main measurement and control system sends the corresponding command content to the measurement and control subsystem and outputs the control to complete various functions. In addition, the main measurement and control system forms two curves on the LCD in real time for the measured current value and the current value read from the meter and stores them. The control circuit mainly realizes the control of the positioning electromagnet in the metering box. The positioning electromagnet mainly realizes the locking control of the metering box door. When the positioning electromagnet coil is energized in the positive direction, the positioning bolt of the electromagnet locks the metering box door. When the power is energized in the reverse direction, the positioning bolt of the electromagnet is released and the metering box door can be opened. Figure 3 is the circuit diagram of the output control electromagnet.

When PTC3 and PTF6 are both high level, the electromagnet coil is energized in the positive direction, locking the metering box door and preventing it from being opened. When it needs to be opened, PTF7 and PTC0 are both high level, the electromagnet is released, and the metering box door can be opened.

Figure 3 Output control circuit of electromagnet [page]

1.2 Selection of single chip microcomputer

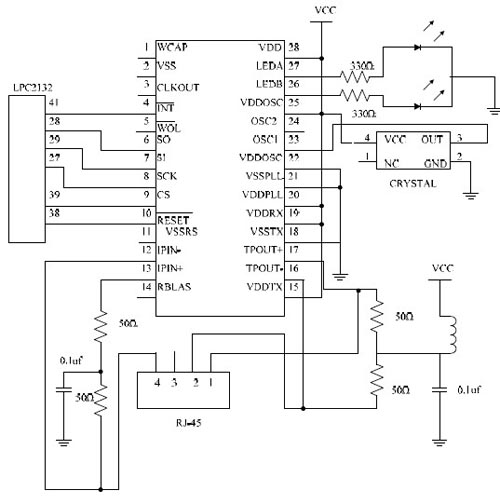

The design uses the PHILIPS LPC2132 chip based on ARM architecture as the MCU of the data acquisition terminal. The LPC2132 microcontroller is based on a 32-bit ARM7TDMI-SCPU that supports real-time simulation and embedded tracing, and has 64 kB of high-speed Flash memory. The

128-bit wide memory interface and unique acceleration structure enable 32-bit code to run at the maximum clock rate. The remote data acquisition system is connected to the Ethernet through the network interface module. The remote computer sends a task request or the acquisition system actively transmits data to the remote monitoring computer to realize the interconnection between the device and the Internet.

1.3 Selection of network interface chip

The design uses the 28-pin independent Ethernet controller ENC28J60 launched by Microchip Technology (Microchip Technology, USA); the EIA/568A wiring standard of the RJ45 connector network cable is adopted, and the transmission medium uses an eight-core twisted pair cable with an RJ45 connector as the interface.

The design of the network interface circuit is based on the functions, timing and logic levels of LPC2132 and ENC28J60. The network interface circuit is shown in Figure 4.

Figure 4 Network interface circuit

1.4 Serial Bus Interface

LP C2132 has two UART serial interface modules, which can be easily connected to serial devices. In the design, UART0 is used as RS232 interface and UART1 is used as RS485 interface. RS232 is mainly used for system debugging and can also be connected to devices using RS232 communication. RS485 is used as the input and output channel of the gateway.

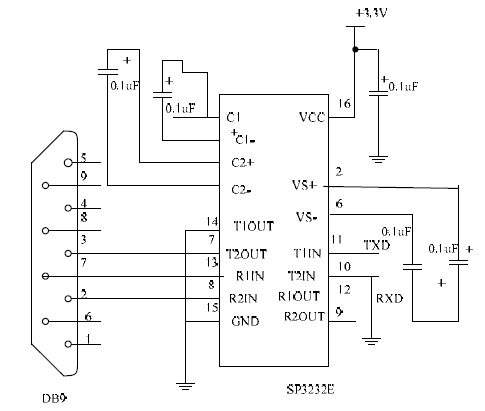

1.4.1 RS-232 conversion circuit

The design uses SP3232E chip. It can convert the input level to standard TTL level (for MCU) and can also convert the input TTL level to negative logic level (for PC). Its working circuit is shown in Figure 5.

Figure 5 SP3232E circuit

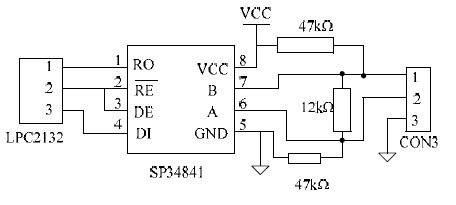

1.4.2 RS485 interface circuit

The design uses Sipex's low-voltage RS485 interface chip SP3481, which only needs a +3.3 V power supply to generate the 1.5 V voltage difference required for differential output. SP3481E works in half-duplex mode. The chip includes a driver and a receiver, and has 8 pins on the outside. The

R/D signal output by LPC2132 directly controls the transmitter/receiver enable of the SP3481 chip: when the R/D signal is "1", the transmitter of the SP3481 chip is valid and the receiver is disabled. At this time, LPC2132 can send data bytes to the RS485 bus; when the R/D signal is "0", the transmitter of the SP3481 chip is disabled and the receiver is valid. At this time, LPC2132 can receive data bytes from the RS-485 bus. As shown in Figure 6. In this circuit, only one of the "receiver" and "transmitter" in the SP3481 chip can be in working state at any time.

2 Conclusion

With the widespread application of electronic technology, intelligent anti-theft control technology will become a development trend. This paper proposes to use gateways and new sensors to test transformer parameters. The debugging results show that the system is highly reliable and easy to use. The anti-theft intelligent control system established by the above method has the characteristics of simple wiring, stable system controller, and high data transmission reliability. It has achieved good results in actual use and has certain promotion significance.

Previous article:Design of rotary encoder acquisition module based on ARM

Next article:Design of Smart Meter System in Smart Grid AMI

Recommended ReadingLatest update time:2024-11-16 21:45

- Popular Resources

- Popular amplifiers

-

Design of dual-drive electric vehicle control system based on LPC2132

Design of dual-drive electric vehicle control system based on LPC2132 -

Development of a comprehensive monitoring instrument for power grid parameters based on ARM

Development of a comprehensive monitoring instrument for power grid parameters based on ARM -

Full set of ZLG LPC2132ARM development materials and programs

Full set of ZLG LPC2132ARM development materials and programs -

MP3 produced by ARM7 lpc2132+vs1003+sdcard This program is compiled in ADS1.2 environment

MP3 produced by ARM7 lpc2132+vs1003+sdcard This program is compiled in ADS1.2 environment

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- ADI New Chinese Information (November 2019)

- [GD32F310 Review] The board has not yet arrived, so we will distribute it first

- DSP system design - interference and board layout related issues

- [NUCLEO-L552ZE Review] +Serial port printing is finally successful!

- Today at 10:00 am TI Award Live: Low-power wireless technology for building automation sensor applications

- EEWORLD University Hall----Live Replay: TI Sitara? Latest AM64X Platform Introduction

- [Project source code] FPGA-based digital tube font, used to display numbers on the LCD screen

- MSP430g2553 hardware UART (modification based on official routines)

- Antenna transmission line standing wave conversion conjugate matching

- Getting Started with the ST SensorTile.box Sensor Kit (5) Bluetooth Connection

Design of dual-drive electric vehicle control system based on LPC2132

Design of dual-drive electric vehicle control system based on LPC2132 Full set of ZLG LPC2132ARM development materials and programs

Full set of ZLG LPC2132ARM development materials and programs

京公网安备 11010802033920号

京公网安备 11010802033920号