Many mobile applications such as wireless access account management, data processing and medical monitoring require high accuracy in measuring the remaining battery capacity to avoid sudden shutdowns due to battery exhaustion. However, it is difficult to ensure the accuracy of measuring the remaining power over the entire battery life cycle, overtemperature or when using loads, which is underestimated by end users and even some system designers. The main reason is that the available power of the battery is a function of its discharge rate, operating temperature, aging and self-discharge characteristics. Developing an algorithm to accurately define the battery's self-discharge characteristics and the impact of aging on battery capacity is almost impossible. Furthermore, traditional battery fuel gauges require the battery to be fully charged and fully discharged to update the battery capacity, which rarely happens in real applications, resulting in greater measurement errors. Therefore, it is difficult to accurately predict the remaining battery capacity and operating time during the battery operation cycle.

This article will introduce how to use the latest battery fuel measurement technology, impedance tracking measurement technology, to solve the above problems. The article will also list a simple design case of a single-cell lithium-ion battery pack solution.

Problems with existing fuel measurement technology

It is a common misconception that the decline in lithium-ion battery capacity is the main reason for the shortened battery operation time. In fact, the continuous increase in battery impedance (rather than the decline in battery capacity) is the key factor that leads to shortened battery operation time and premature system shutdown. Within about 100 battery charge and discharge cycles, the battery capacity only decreases by 5%, while the battery's DC impedance increases by a factor of one or two. The direct result of the increased impedance of an aging battery is the increase in the internal voltage drop caused by the load current. As a result, the aging battery reaches the system's minimum operating voltage (or termination voltage) much earlier than a new battery.

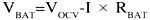

Traditional battery fuel measurement technology is mainly developed based on voltage and coulomb counting algorithms, and has obvious limitations in measurement performance. Voltage-based measurement methods are widely used in handheld devices such as mobile phones due to their low cost and simple implementation. However, the battery impedance will change after a period of use, affecting the measurement accuracy of this method. The battery voltage can be obtained by the following formula:

Where Vocv is the battery open circuit voltage and RBAT is the battery internal DC impedance. As can be seen from Figure 1, the voltage of an aging battery is lower than that of a new battery, which will cause the system to shut down earlier.

Load conditions and temperature changes can reduce the available battery capacity by up to 50%. Most end users have experienced sudden shutdowns caused by battery exhaustion when using portable devices that are not equipped with true fuel gauges. Coulomb counting, on the other hand, takes a different approach: by continuously integrating the coulombs, the amount of charge consumed and the state of charge (SOC) are calculated, and the total capacity is known, so the remaining capacity value can be obtained. The disadvantage of this method is that it is difficult to accurately quantify (model) the self-discharge capacity, and because this method does not perform periodic full cycle corrections, the measurement error increases over time. None of these algorithms address the problem of changes in battery impedance. To prevent sudden shutdown, designers must terminate system operation early and retain more energy, which results in a lot of power being wasted.

Dynamic Monitoring of Battery Impedance and Chemical Capacity

Impedance Tracking (IT) technology is unique and more accurate than existing solutions because it has a self-learning mechanism that accounts for aging that causes changes in battery impedance and chemical full capacity (QMAX) under no-load conditions. Impedance Tracking uses a dynamic simulation algorithm to learn and track battery characteristics by measuring impedance and capacity values and then tracking their changes during actual battery use. This algorithm eliminates the need for periodic full cycle capacity calibrations.

The knowledge of battery impedance enables accurate load and temperature compensation. Most importantly, by dynamically learning the battery parameters, this measurement method provides an accurate measurement of charge over the life of the battery. Impedance Tracking is superior in measuring the remaining capacity of a battery compared to coulomb counting or cell voltage correlation alone.

IT requires the continuous maintenance of a table database that maintains the functional relationship between the battery impedance (RBAT) and the depth of discharge (DOD) and temperature. Understanding what is happening in different states helps determine when these tables need to be updated or used. In the meter, nonvolatile memory stores multiple current thresholds that define states such as charge, discharge, relaxation after charge, and relaxation after discharge. After charging or discharging stops, the "relaxation time" allows the battery voltage to stabilize.

Before the handheld device is turned on, the battery's open circuit voltage (OCV) is measured and then compared to the OCV (DOD, T) table to determine the battery's exact charge state. When the handheld device is active and connected to a load, the coulomb counting algorithm based on current integration begins. The coulomb counter measures the amount of charge passed and integrates it to continuously calculate the SOC value.

The total capacity QMAX can be calculated from two OCV readings when the battery voltage change before and after charging or discharging is small enough and the battery is in a fully relaxed state. For example, before the battery is discharged, the SOC can be calculated as follows: When the

battery is discharged and the charge passed is ΔQ, the SOC can be calculated as follows:

Subtracting the two equations gives:

As can be seen from the equation, the total capacity of the battery can be determined without going through a full charge and discharge cycle. This also eliminates the time-consuming battery learning cycle during battery pack production.

The RBAT (DOD, T) table is continuously updated during the discharge process. IT uses this table to calculate when the termination voltage is reached under the current load and temperature conditions. The overall battery impedance increases as the battery ages and the number of charge and discharge cycles increases. The impedance can be obtained as follows

With the battery impedance information, the remaining capacity (RM) can be determined using the voltage simulation algorithm contained in the firmware program instructions in the read-only memory. The simulation algorithm first calculates the current SOCstart value and then calculates the future battery voltage value under the same load current and the SOC value continues to decrease. When the simulated battery voltage VBAT (SOCI, T) reaches the battery termination voltage (typically 3.0V), the SOC value corresponding to this voltage is obtained and recorded as SOCFINAL.

Impedance Tracking Single-Cell Battery Fuel Monitor Test Results

The impedance tracking lithium-ion single-cell battery pack circuit is shown in Figure 2. The battery voltage is measured through the BAT2 pin input and the current is monitored through the coulomb counter differential signal inputs (SRP and SRN). The system uses a fuel gauge to obtain information such as SOC and Run-Time-to-Empty from the single-wire SDQ communication port.

IT fuel gauges can accurately predict the remaining battery capacity even when the load varies. For example, when a digital camera is in different operating modes, the load on the battery is also different. Figure 3 shows how an IT fuel gauge can accurately predict the remaining battery capacity. The error rate of the remaining capacity prediction can be less than 1%. And because the battery impedance and aging effects used to predict the remaining capacity can be updated in real time, this small error can be maintained throughout the battery's entire service life.

The impedance tracking battery fuel gauge combines the advantages of the coulomb counting algorithm and the voltage correlation algorithm to achieve higher battery fuel monitoring accuracy. Measuring OCV in a relaxed state can obtain an accurate SOC value. Since all self-discharge activities are reflected during the battery OCV reduction process, no self-discharge correction is required. When the device is in active mode and connected to a load, the coulomb counting algorithm based on current integration begins to execute. The battery impedance is updated through real-time measurement.

Previous article:Design and implementation of intelligent charger for lithium battery based on AVR

Next article:Design of Power Management System for S3C2440A Embedded Handheld Terminal

- Popular Resources

- Popular amplifiers

-

Battery Management Systems for Electric and Hybrid Vehicles

Battery Management Systems for Electric and Hybrid Vehicles -

Understanding and overcoming the challenges of building high voltage automotive battery management

Understanding and overcoming the challenges of building high voltage automotive battery management -

Battery Management System Solutions: 36 V and beyond from BMS ICs to the MCU

Battery Management System Solutions: 36 V and beyond from BMS ICs to the MCU -

Electric Vehicle Wireless Battery Management Revolution Has Begun and the ROI Potential Is Huge

Electric Vehicle Wireless Battery Management Revolution Has Begun and the ROI Potential Is Huge

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Software - Can I use the Breaking Master on my computer to install Allegro 16.6 and 17.4 at the same time?

- CC3120 Wireless Network Processor BoosterPack Plug-in Module

- Simulink and ModelSim co-simulation to realize BLDC six-step square wave closed-loop control system

- [NUCLEO-L552ZE review] + driving LCD19264 display

- GD32103E-EVAL Full-function evaluation board with screen

- Free application: Infineon's revolutionary photoacoustic spectroscopy (PAS) CO2 sensor, the legend of excessive CO2 leads to lack of attention

- Working principle of two matched transistor pairs

- I can't figure out the op amp formula, can someone help me look at it?

- GD32E231C-START unboxing first time

- [Repost] Popular Science of Components: Semiconductor Lasers

Battery Management Systems for Electric and Hybrid Vehicles

Battery Management Systems for Electric and Hybrid Vehicles

京公网安备 11010802033920号

京公网安备 11010802033920号