Hello everyone, what method do you usually use to detect signal timing? Today I will share with you a method of using the setup/hold trigger mode to detect signal timing.

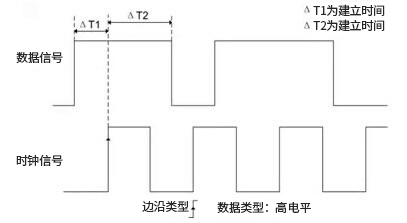

Before the sampling clock signal arrives, the data must remain stable for a period of time, that is, ΔT1 in the figure is called the setup time; if the setup time is not long enough, the data will not be able to be transmitted stably. After the sampling clock signal arrives, the data must also remain stable for a period of time, that is, ΔT2 in the figure is called the hold time; if the hold time is not long enough, the data will also not be able to be transmitted stably.

The trigger holdoff function is specially designed for large-cycle repetitions where there are many non-repeating waveform points that meet the trigger conditions. If the holdoff function is not used, the trigger point is not fixed, which will cause unstable display. After the oscilloscope uses the trigger holdoff function, after the oscilloscope is triggered for the first time, the second trigger can only be performed after the trigger holdoff time has passed. In the figure, the holdoff time can be set to a value of >200 ns but <600 ns. After using trigger holdoff, the trigger is triggered at the same point each time, so the display can be stable.

Figure 1 Setup and hold time

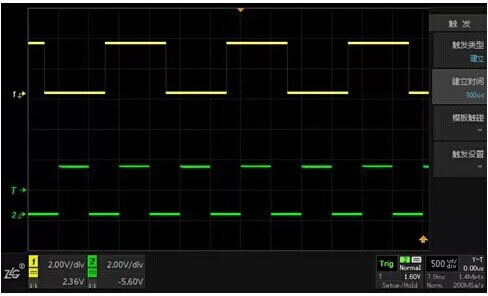

In order to determine whether the setup time and hold time of data transmission meet the design requirements, we use the setup/hold trigger mode. Press the [Trigger] key, set the trigger mode to normal, set the trigger type to setup/hold, and then set the corresponding clock channel and data channel. The sampling type is divided into rising edge and falling edge. The edge here means that you can specify which clock edge to sample the data. We select the rising edge, and the data type can be selected as high level and low level. We select high level and select the next page soft key. In the trigger type here, we first select setup. The next step is to set the setup time. Set the appropriate setup time according to your needs. Rotate knob A for fine adjustment and knob B for coarse adjustment. We set it to 300us. It will trigger when the setup time is less than the set time. Find the required high and low levels through the edge of the clock.

Figure 2: Creating a trigger

This trigger ensures the high-level logic state of the data signal corresponding to the rising edge of the clock, and the location of the establishment time trigger is accurately positioned at the rising edge of the clock.

In fact, the steps to maintain a trigger are similar to those to establish a trigger. Let’s try it.

Previous article:ZDS2022 Oscilloscope 100 Practical Videos 55: Trigger Hold Off

Next article:ZDS2022 Oscilloscope 100 Practical Videos 57: 7 One-button Operations

Recommended ReadingLatest update time:2024-11-16 19:32

- Popular Resources

- Popular amplifiers

-

FOUNDRY PROCESS QUALIFICATION GUIDELINES – TECHNOLOGY QUALIFICATION VEHICLE TESTING JEP001-3B

FOUNDRY PROCESS QUALIFICATION GUIDELINES – TECHNOLOGY QUALIFICATION VEHICLE TESTING JEP001-3B -

CVPR 2023 Paper Summary: Vision Applications and Systems

CVPR 2023 Paper Summary: Vision Applications and Systems -

CVPR 2023 Paper Summary: Transparency, Fairness, Accountability, Privacy, Ethics in Vision

CVPR 2023 Paper Summary: Transparency, Fairness, Accountability, Privacy, Ethics in Vision -

ICCV2023 Paper Summary: Self-, Semi-, Meta-, Unsupervised Learning

ICCV2023 Paper Summary: Self-, Semi-, Meta-, Unsupervised Learning

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- How can I reduce the brightness of the four-digit digital tube? If I don't change the program, what hardware should I change?

- Compilation error, please help me! ! !

- Recruitment: Beijing high-power switching power supply R&D manager

- Can the STM32 DMA be set to an interrupt with any index?

- Ground pad processing issues in AD package library

- I want to buy a complete solution based on HiSilicon 3516EV200 or similar HiSilicon chips.

- MS2351M replaces AD8314 RF power detection chip

- Method for software simulation of core reset of SinoWise M0+ core chip

- Factors to consider when allocating FPGA pins

- Qian Xuesen named VR Lingjing 30 years ago

FOUNDRY PROCESS QUALIFICATION GUIDELINES – TECHNOLOGY QUALIFICATION VEHICLE TESTING JEP001-3B

FOUNDRY PROCESS QUALIFICATION GUIDELINES – TECHNOLOGY QUALIFICATION VEHICLE TESTING JEP001-3B CVPR 2023 Paper Summary: Vision Applications and Systems

CVPR 2023 Paper Summary: Vision Applications and Systems

京公网安备 11010802033920号

京公网安备 11010802033920号