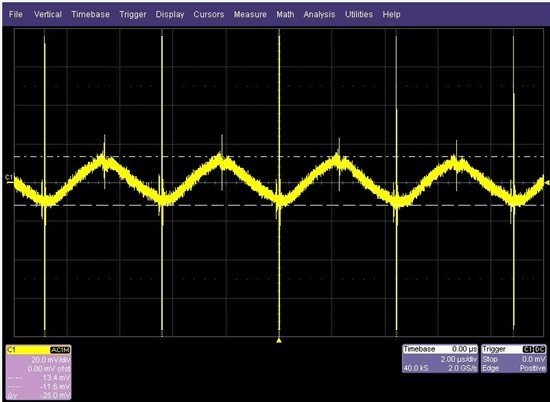

Today, I want to talk about another important metric to consider when testing power supply performance: noise measurement.

Where does power supply noise come from?

Power supply noise is generated from a number of different sources. Like any amplifier, the power supply generates various types of noise, and switch-mode designs also need to deal with the inherent switching noise that occurs. Switching supplies can be designed to minimize their switching noise, and output filters can be incorporated to further reduce this noise. However, the exact level of noise generated by a power supply can only be known after actual measurement.

Transient ripple noise

Why measure noise?

Bias voltages within any system are, as I see it, the foundation of electrical circuits. All systems can interface with these supplies and must deal with the noise associated with them. If the noise generated from (or through) the supply exceeds the tolerance of the circuit, the system will automatically fail. The problem with noise is that it may not (at least not always) cause catastrophic failure issues, but sometimes it can cause intermittent errors that may not be obvious when the system is thoroughly tested in a specific environment with a range of typical component values, but can cause all kinds of problems later. In some cases, I have seen software patches written to "mask" temporary system errors that may have been caused by power supply noise issues. Is it the best way to fix problems in software that may have been fixed in the power supply? I beg to differ, but I don't want to turn the topic into a philosophical discussion, so I'll save that for a follow-up article, "Fixing Errors, Software vs. Hardware"...

I have sometimes seen noisy power supply designs cause systems to fail EMI testing and slow product releases. These slowdowns could have been avoided if the noise issues were properly tested and addressed early in the design process. When it comes to biasing analog circuits, power supply noise can cause poor system performance, potentially reducing the end customer value of the product. Think about the power supply issues in the analog signal path of some sensors. In such systems, noise will directly affect the sensitivity of the system, and the higher the noise floor, the lower the sensitivity. If designers take the time to actually measure and analyze the noise generated by the power supply, they can either accept the performance or often make changes to avoid system-level problems later, at little additional cost. The cost of testing and potentially modifying the power supply is often much less than the cost of debugging and modifying the system level later, or the cost of poor performance after the product is released.

It's this attention to detail that makes the difference between an average product and one that delivers the highest performance and reliability.

Previous article:9205 digital multimeter working principle circuit and its measurement circuit

Next article:Principle and Design of Magnetic Induction Flowmeter

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Energy data collection based on blockchain

- I hope someone can help me see if my minimum system schematic diagram of TM4C123G is correct.

- In a synchronous rectification circuit, what is the function of connecting an NMOS in reverse series to the lower bridge arm?

- Hard disk video recorder motherboard manufacturer

- Introducing an active circuit - operational amplifier

- [National Technology N32WB452 Review] 2. Some communication interface tests (USART, SPI, I2C)

- 4G/5GDTU/router, ZigBee module, WIF, Bluetooth wireless transmission characteristics and applications

- Wireless Communication Principles and Applications (Second Edition Chinese Edition)

- Miller Effect in MOSFET Gate Drive

- Unboxing K210 & STM32F7508-DK

Signal Integrity and Power Integrity Analysis (Eric Bogatin)

Signal Integrity and Power Integrity Analysis (Eric Bogatin)

京公网安备 11010802033920号

京公网安备 11010802033920号