As one of the liquid level measuring instruments used in a large number of storage tank areas, the magnetic flap level gauge has its own advantages over other types of instruments. In many cases, the magnetic flap level gauge has become the preferred product for measuring liquid tank areas because of its simple structure, intuitive reading, good working stability, large measuring range, and no restrictions on the height of the storage tank. In addition, it is easy to install (side-mounted and top-mounted), which has been favored by many companies. The

magnetic flap level gauge is also called a magnetic level gauge, a magnetic column level gauge, and a magnetic float level gauge. Its working principle is that it uses the principle of magnetic coupling. The emergence of the magnetic flap level gauge is an important technological advancement compared to the previous glass tube level gauge. It makes up for the disadvantage that the glass tube level gauge is easy to break when working under high temperature and high pressure, and eliminates the impact of the broken measuring tube on production and personal injury to operators.

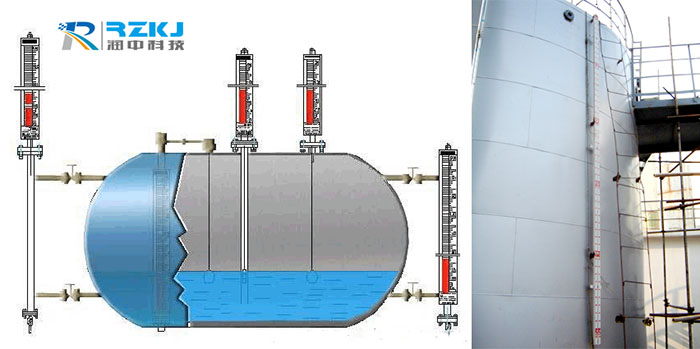

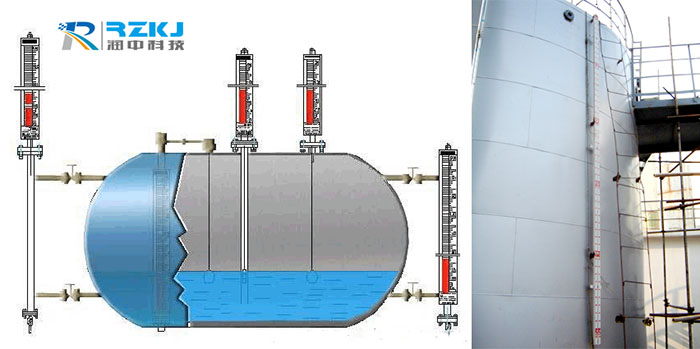

The installation methods of magnetic flap level gauges are divided into top-mounted and side-mounted. In industrial applications, there will definitely be various storage tanks on site, including horizontal tanks, underground tanks, and high-length tanks. Since the top-mounted installation method lacks support, the maximum recommended height should not exceed 5 meters. The measurement range of the side-mounted type can be selected at will, and there is generally no problem with a 10-meter tank. How to choose the side-mounted and top-mounted installation methods should be selected according to the specific requirements of the production site and the specific conditions of the tank. What installation tips should we pay attention to when choosing a magnetic flap level gauge? The following is a summary:

Issues that need to be paid attention to when installing a top-mounted magnetic plate level gauge:

The connection part between the top-mounted magnetic flap level gauge and the tank body is generally equipped with a DN80 or DN100 flange connection. If you feel that it is not firm enough, you can choose a larger specification connection flange according to the actual situation. In general, DN80 and DN100 are sufficient. When the top-mounted magnetic flap level gauge is installed at a height of 4 to 5 meters, it is recommended to add fixed cables on both sides to ensure that the instrument will not be damaged in a harsh measurement environment, such as large vibrations on site or sometimes collisions. Issues that need to be paid attention to when installing

the side-mounted magnetic flap level gauge

: the liquid level height of the magnetic flap level gauge and technical influence. For example: when measuring a 10-meter high liquid level tank, if you directly choose to make a 10-meter long magnetic flap level gauge, the first product will be clumsy; second, it will be inconvenient to transport, so it is recommended to reasonably adopt segmentation processing, so that there will be no technical errors (blind spot influence). The advantage of the magnetic flap level gauge is that it can be installed in parts. That is to say, divide 10 meters into two or three sections, and connect each section with flanges. This will not only facilitate transportation, but also greatly reduce costs. Users only need to use ordinary tools to dock the flanges between the three sections after receiving the goods. As for corrosion protection and leakage, we have also taken them into consideration. Specific problems are analyzed specifically. The magnetic flap level gauge can be equipped with electric remote transmission and output a standard signal of 4 to 20 mA to cooperate with recording instruments or industrial control computer networking.

10 meters and above is a bit long. Regardless of whether it is segmented or not, it is recommended to fix it with a clamp or other fixings around the flange of the middle part or each segment. When installing the magnetic flap level gauge, the magnetic flap level gauge must be kept in a vertical state. A ball valve should be installed between the magnetic flap level gauge and the container lead pipe to facilitate the maintenance and disassembly and cleaning of the level gauge. The side-mounted lined magnetic flap level gauge (PP) is suitable for the measurement of inorganic corrosive liquids such as hydrochloric acid and dilute sulfuric acid.

The side-mounted lined magnetic flap level gauge (PTFE) is suitable for level measurement in corrosive media and high working temperature. It uses the leading new technology of stainless steel lined polytetrafluoroethylene stretch flanging, which has a reliable structure and a long service life. It is the best choice for measuring the level of highly corrosive media such as hydrofluoric acid. Before use, the small ball below the zero position should be set to red with a calibration magnet, and the other balls should be set to white.

Reference address:Analysis of installation techniques for magnetic flap level gauges used in high-level tanks

magnetic flap level gauge is also called a magnetic level gauge, a magnetic column level gauge, and a magnetic float level gauge. Its working principle is that it uses the principle of magnetic coupling. The emergence of the magnetic flap level gauge is an important technological advancement compared to the previous glass tube level gauge. It makes up for the disadvantage that the glass tube level gauge is easy to break when working under high temperature and high pressure, and eliminates the impact of the broken measuring tube on production and personal injury to operators.

The installation methods of magnetic flap level gauges are divided into top-mounted and side-mounted. In industrial applications, there will definitely be various storage tanks on site, including horizontal tanks, underground tanks, and high-length tanks. Since the top-mounted installation method lacks support, the maximum recommended height should not exceed 5 meters. The measurement range of the side-mounted type can be selected at will, and there is generally no problem with a 10-meter tank. How to choose the side-mounted and top-mounted installation methods should be selected according to the specific requirements of the production site and the specific conditions of the tank. What installation tips should we pay attention to when choosing a magnetic flap level gauge? The following is a summary:

Issues that need to be paid attention to when installing a top-mounted magnetic plate level gauge:

The connection part between the top-mounted magnetic flap level gauge and the tank body is generally equipped with a DN80 or DN100 flange connection. If you feel that it is not firm enough, you can choose a larger specification connection flange according to the actual situation. In general, DN80 and DN100 are sufficient. When the top-mounted magnetic flap level gauge is installed at a height of 4 to 5 meters, it is recommended to add fixed cables on both sides to ensure that the instrument will not be damaged in a harsh measurement environment, such as large vibrations on site or sometimes collisions. Issues that need to be paid attention to when installing

the side-mounted magnetic flap level gauge

: the liquid level height of the magnetic flap level gauge and technical influence. For example: when measuring a 10-meter high liquid level tank, if you directly choose to make a 10-meter long magnetic flap level gauge, the first product will be clumsy; second, it will be inconvenient to transport, so it is recommended to reasonably adopt segmentation processing, so that there will be no technical errors (blind spot influence). The advantage of the magnetic flap level gauge is that it can be installed in parts. That is to say, divide 10 meters into two or three sections, and connect each section with flanges. This will not only facilitate transportation, but also greatly reduce costs. Users only need to use ordinary tools to dock the flanges between the three sections after receiving the goods. As for corrosion protection and leakage, we have also taken them into consideration. Specific problems are analyzed specifically. The magnetic flap level gauge can be equipped with electric remote transmission and output a standard signal of 4 to 20 mA to cooperate with recording instruments or industrial control computer networking.

10 meters and above is a bit long. Regardless of whether it is segmented or not, it is recommended to fix it with a clamp or other fixings around the flange of the middle part or each segment. When installing the magnetic flap level gauge, the magnetic flap level gauge must be kept in a vertical state. A ball valve should be installed between the magnetic flap level gauge and the container lead pipe to facilitate the maintenance and disassembly and cleaning of the level gauge. The side-mounted lined magnetic flap level gauge (PP) is suitable for the measurement of inorganic corrosive liquids such as hydrochloric acid and dilute sulfuric acid.

The side-mounted lined magnetic flap level gauge (PTFE) is suitable for level measurement in corrosive media and high working temperature. It uses the leading new technology of stainless steel lined polytetrafluoroethylene stretch flanging, which has a reliable structure and a long service life. It is the best choice for measuring the level of highly corrosive media such as hydrofluoric acid. Before use, the small ball below the zero position should be set to red with a calibration magnet, and the other balls should be set to white.

Previous article:Research and discussion on online calibration method of electromagnetic flowmeter in water injection station

Next article:Analysis and solution of inaccurate measurement of clamp-on ultrasonic flowmeter

- Popular Resources

- Popular amplifiers

Recommended Content

Latest Test Measurement Articles

- Modern manufacturing strategies drive continuous improvement in ICT online testing

- Methods for Correlation of Contact and Non-Contact Measurements

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

MoreSelected Circuit Diagrams

MorePopular Articles

- Intel promotes AI with multi-dimensional efforts in technology, application, and ecology

- ChinaJoy Qualcomm Snapdragon Theme Pavilion takes you to experience the new changes in digital entertainment in the 5G era

- Infineon's latest generation IGBT technology platform enables precise control of speed and position

- Two test methods for LED lighting life

- Don't Let Lightning Induced Surges Scare You

- Application of brushless motor controller ML4425/4426

- Easy identification of LED power supply quality

- World's first integrated photovoltaic solar system completed in Israel

- Sliding window mean filter for avr microcontroller AD conversion

- What does call mean in the detailed explanation of ABB robot programming instructions?

MoreDaily News

- STMicroelectronics IO-Link Actuator Board Brings Turnkey Reference Design to Industrial Monitoring and Equipment Manufacturers

- Melexis uses coreless technology to reduce the size of current sensing devices

- Melexis uses coreless technology to reduce the size of current sensing devices

- Vicor high-performance power modules enable the development of low-altitude avionics and EVTOL

- Chuangshi Technology's first appearance at electronica 2024: accelerating the overseas expansion of domestic distributors

- Chuangshi Technology's first appearance at electronica 2024: accelerating the overseas expansion of domestic distributors

- "Cross-chip" quantum entanglement helps build more powerful quantum computing capabilities

- Ultrasound patch can continuously and noninvasively monitor blood pressure

- Ultrasound patch can continuously and noninvasively monitor blood pressure

- Europe's three largest chip giants re-examine their supply chains

Guess you like

- ISD4003 series high fidelity voice recording and playback IC

- Three closed loop servo motor motion control

- How to build a 3D parts library in AD14.3

- The latest technology trends of FPC

- Two-input AND gate engineering files and test files

- Design of a dual 10A output switching power supply based on L4970A

- Application of HT46R47 in mobile phone charger

- Help others and achieve self-realization——EEWORLD Q&A List (11th issue)

- EEWORLD University ---- TI-RSLK Module 14 - Real-time Systems

- Design of digital phase-shift trigger unit based on CPLD

5962-8687701QPA

5962-8687701QPA

京公网安备 11010802033920号

京公网安备 11010802033920号