1 Overview

Reference address:Battery Management System HIL Test Solution

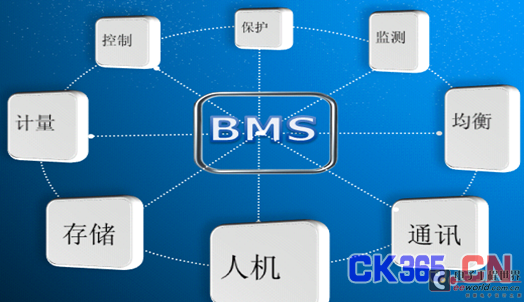

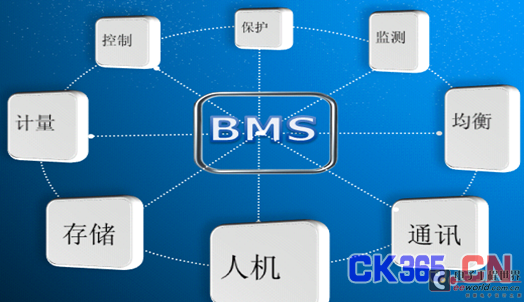

The Battery Management System (BMS) is an increasingly important key part in electric vehicles and a core component in key technologies for monitoring operation and protecting batteries.

Figure 1-1 BMS functions

There are many disadvantages to using real battery packs to test BMS:

• Extreme operating condition simulation brings safety risks to testers, such as overvoltage, overcurrent and overtemperature, which may cause battery explosion.

• The SOC estimation algorithm verification takes a long time, and the actual battery pack charge and discharge test takes a week or even longer.

• It is difficult to simulate specific working conditions, such as the slight SOC difference between battery cells during the equalization function test, and the slight temperature difference between the battery cell and the battery pack during the battery thermal balance test.

• As well as other BMS functional tests, such as battery pack operating voltage, single cell voltage, temperature, SOC calculation function, charge and discharge control, battery thermal balance, high voltage safety function, equalization function, communication, fault diagnosis, sensors and other tests, OEMs are faced with many challenges.

2. Solution

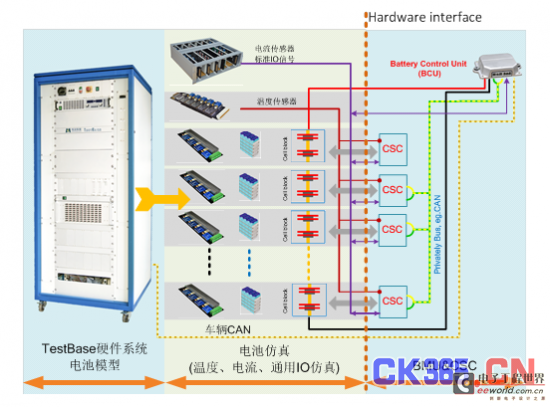

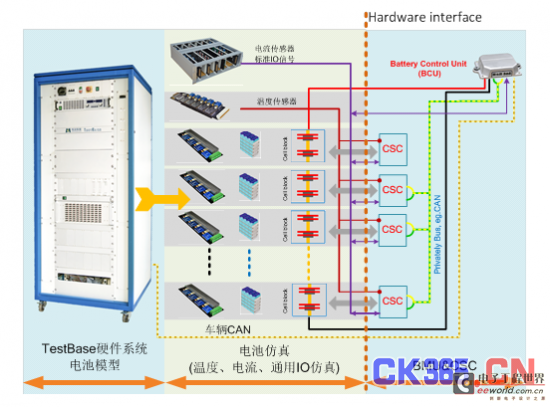

In the face of the above challenges, Hirain Technology provides a BMS HIL test solution based on TestBase. The system solution mainly includes the following parts:

• Real-time simulation platform: Developed based on the PXI bus series boards provided by NI , it consists of real-time processors, real-time I/O boards, etc., and can perform fast data calculations.

• Battery simulation board: used for single cell simulation. Combined with the battery simulation model, it can dynamically output the voltage and temperature of the single cell;

• Battery simulation model: It adopts the equivalent circuit principle to model and calculate the voltage, current, temperature, SOC and other state quantities of the battery when it is working.

Figure 2-1 Overall solution for battery simulation

The above system solution uses the battery cell simulation module independently developed by Hirain Technology, which has been successfully applied to the BMS HIL projects of new energy vehicles of multiple OEMs.

Application Areas

• Simulation of battery modules or cells;

• BMS balancing, insulation and SOC estimation algorithm verification;

• BMS charging and discharging, high voltage safety testing;

• Communication and functional verification based on actual vehicle conditions.

Features

• Achieve voltage simulation of up to 150 cells by connecting in series;

• Conveniently and accurately realize battery temperature and insulation detection;

• Realize high voltage power on/off and pre-charge relay control;

• Accurately simulate the characteristics of each battery cell and simulate each sensor;

• Meet CAN, LIN and SENT communication protocols;

• IO and equipment can be customized according to the customer's actual BMS.

3. Product features and advantages

3.1.Battery simulation model principles and characteristics:

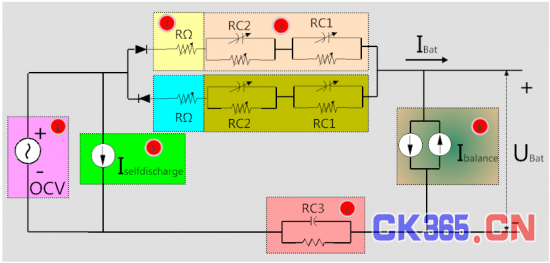

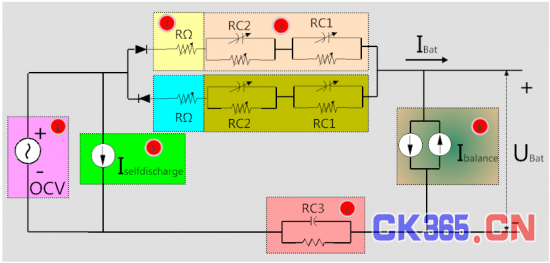

The battery simulation model is based on the equivalent circuit method and takes into account the impact of factors such as polarization loss and self-discharge loss at different stages of the battery cell on the battery voltage and SOC, which significantly improves the steady-state and transient response of the battery model. The modeling principle is shown in Figure 3-1.

Figure 3-1 Battery simulation model principle

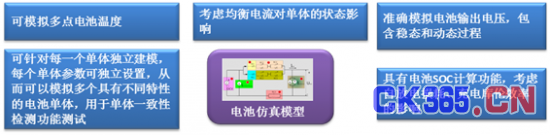

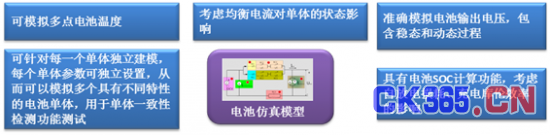

The battery model function is shown in Figure 3-2:

Figure 3-2 Battery simulation model characteristics [page]

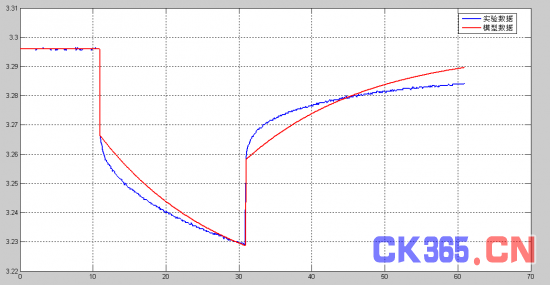

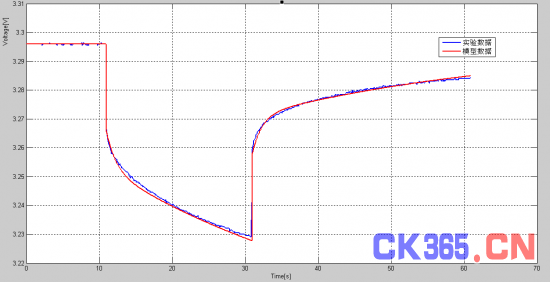

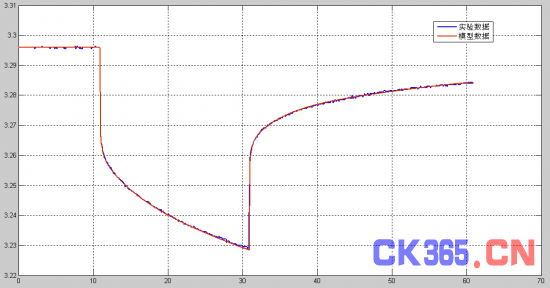

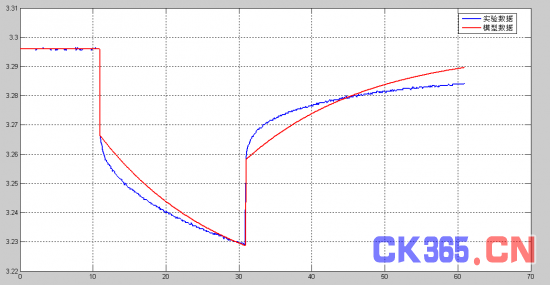

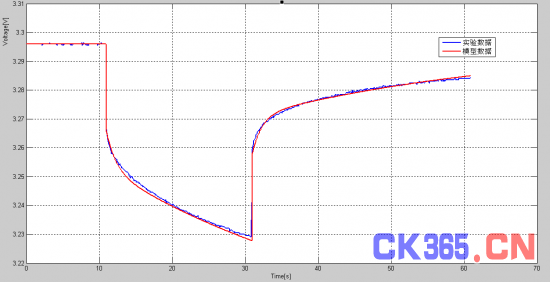

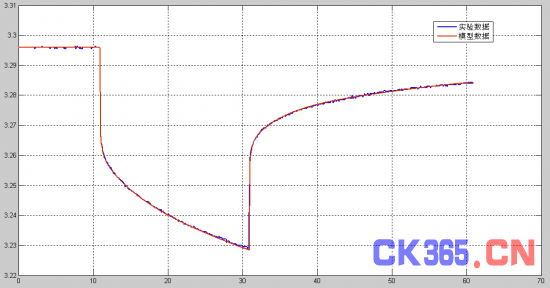

The comparison between the battery single-cell pulse discharge test simulation curve and the real single-cell pulse discharge curve is shown in Figure 3-3:

Figure 3-3 Battery model simulation comparison curve

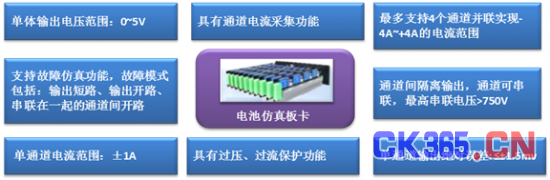

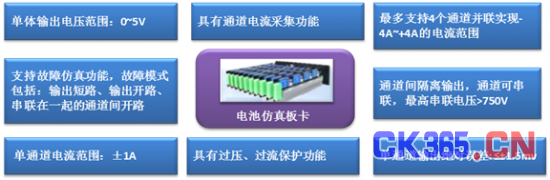

3.2. Battery simulation board functions and features:

After the battery model calculation is completed, the status information of the single battery in the battery model is output to the battery simulation board, such as the single battery voltage signal, and the single battery voltage signal is sent to the BMS daughter board to realize the simulation and test of the single battery voltage. The battery simulation board function is shown in Figure 3-4:

Figure 3-4 Battery board functions and indicators

By combining the resistance simulation board and the insulation resistance simulation board, the temperature and insulation resistance of the single cell can be simulated. The specific parameter indicators are shown in Figure 3-5:

Figure 3-5 Specific parameters of the battery simulation module

4. Summary

Compared with BMS testing using real batteries, HIL testing using battery simulation technology has the following obvious advantages:

• Safe and energy-saving: Avoid high-power charging and discharging processes, and avoid potential safety hazards to testers;

• Easy to create various BMS faults, so as to comprehensively test the BMS diagnostic function;

• Realize simulation of battery packs of various specifications (number of cells, voltage level) through software and hardware configuration;

• Battery status, such as SOC, temperature, etc., can be modified quickly online to improve test efficiency;

• By modifying the model parameters, the battery aging, cell inconsistency and other phenomena can be simulated;

• Can simulate the whole vehicle operating environment.

Previous article:Measurement Technology for Industrial Motion Control

Next article:Wafer-level radio frequency (RF) testing of IC chips

- Popular Resources

- Popular amplifiers

Recommended Content

Latest Test Measurement Articles

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

MoreSelected Circuit Diagrams

MorePopular Articles

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

MoreDaily News

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

Guess you like

- Welcome to the 5G era: There are countermeasures for mobile phone antenna design

- EEWORLD University - Solar System Design Made Simple

- EEWORLD University ---- Medical monitoring and wearable devices

- Photodetector Array Signal Processing

- Application of wireless power transmission technology in underwater transmission

- EEWORLD University Hall----Live Replay: ST's IO-Link-based environmental monitoring and predictive maintenance solutions

- FAQ_About the pulse problem when the output port of BlueNRG-2 remains at a low level in low power mode

- There are still some problems with the PCB diagram drawn by a novice

- 【TGF4042 signal generator】+ Dual channel comparison test

- 3. Microcontrollers used in previous "Control" competitions

Battery Management Systems for Electric and Hybrid Vehicles

Battery Management Systems for Electric and Hybrid Vehicles

京公网安备 11010802033920号

京公网安备 11010802033920号