Danang Juliardi - Indonesian Aerospace

Industry:

Aerospace/AvioNIcs

Products:

Software, Data Acquisition

The Challenge: Reduce the investment cost of aircraft sealing inspection equipment

through innovative testing methods. Increase the accuracy of test results and data reliability through automated process control.

The Solution:

Electronic equipment is used for comprehensive process sequence testing , and the test equipment is controlled by computer . The test system is changed from manual to fully automated method mode. The recording and processing of data test are checked by computer.

"The low-cost virtual instrument system based on user-developed VI is highly cost-effective. LabVIEW, as the key, provides DAQ hardware integrated in the test equipment and automated test plans and documentation. LabVIEW's flexible and friendly graphical programming environment greatly shortens the system development time."

According to FAR 25.841, spacecraft flying at altitudes above 8,000 ft must undergo pressure chamber testing . Until now, this type of testing has been done using traditional methods. The test methods do not allow for direct test results. Parameters need to be written in and calculated manually.

In order to simplify the test steps and improve the accuracy of the test data, we developed a test method based on computers and data acquisition equipment (DAQ). LabVIEW was used to automate the test data flow and data processing. The software application provides a graphical visual interface and a summary of the test results.

System Overview

As mentioned above, the old test method required manual data collection and analysis, which was very inefficient and the test performance was completely dependent on the operator. The operator was required to manually operate, record data, control and monitor the test during all test processes . The new test method has achieved innovative automated testing . We have improved the test steps and achieved computer-controlled data collection and analysis in a single integrated system.

Goals of the innovative test automation process:

● Reduce investment cost of test equipment

● Simplify the testing method

● Automated testing and control methods improve test performance and accuracy

● Independent control system monitoring capability

● Reduce the misinterpretation of test parameters

● Automatically generate test results

● Windows-based software control application

● User-friendly interface

Hardware Implementation

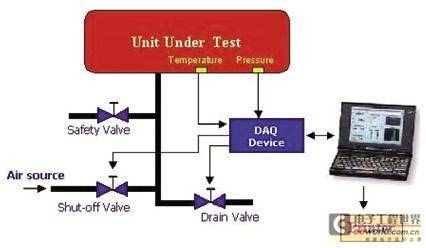

The automatic leak test equipment consists of a computer, data acquisition equipment, solenoid valves, gas source, pressure transmitter and temperature transmitter. The system can accurately, quickly and automatically measure the leakage level of a specific area of the spacecraft pressurized cabin. The computer and DAQ equipment are used to handle process control sequence testing and collect data. The control device controls the state valve at the corresponding value and collects data from the sensor. The leak test system uses a four-channel DAQ device. The channel is connected to the sensor and solenoid valve and wrapped in a cable.

The test process begins by compressing the chamber or unit under test until the pressure reaches a certain value. The pressure and temperature of the chamber environment are measured by sensors or transmitters. The transmitter converts the measured values into current or voltage.

The computer processes the cabin pressure and temperature data collected by the transmitter and DAQ device. When the cabin pressure exceeds the critical value, the solenoid valve will control the flow of the cabin pressure input. Figure 1 is a block diagram of the test system. [page]

Figure 1. Block diagram of the leak test system

Software Implementation

The leakage test system uses DAQ devices and is fully controlled by writing virtual instruments (VIs) using LabVIEW software. LabVIEW can control DAQ devices to read analog input signals (A/D conversion), generate analog output signals (D/A conversion), and read and write digital signals. Voltage data is input into the plug-in DAQ device on the computer and sent to the memory for storage and processing.

We developed the software in the LabVIEW graphical programming environment, ensuring the software's high modularity and scalability. LabVIEW is hierarchical, and any virtual instrument can be quickly converted into a module as a submodule of another VI. We configured the entire software into an independent virtual instrument, which includes a system controller, data acquisition, and data analysis and display.

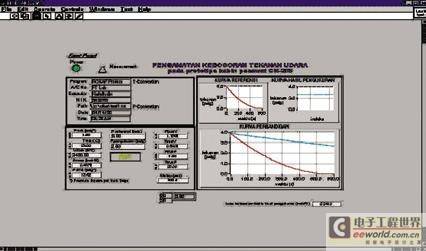

We integrated the seven VIs into the final main VI. Through the graphical user interface (GUI) of the main VI (as shown in Figure 2), users can observe the leak test monitoring process of the pressurized cabin. During the test execution, the computer displays the main LabVIEW VI interface, which includes several menus: user authentication, parameter setting, output waveform drawing, etc. The interface displays "GO" when the test passes, and "NO GO" when the test fails.

Figure 2. Graphical user interface and result display window

The operation of software testing is very simple. First, the test equipment must be installed as the test configuration. Then initialize the parameters or variables, such as pressure, temperature, chamber volume, allowable leakage area, and test duration. After completing all configuration settings, you can start the test . The software functions include system control and data processing. The software can also control the status valve, read sensor data, and process or analyze the collected data.

To monitor the test status on the computer screen, the GUI displays three graphs: ratio curve, reference curve, and measurement result curve. The tank leakage area value and the results of all test processes are also visible. The operator does not need to record data during the test .

The printing of the final test result report is simple, and users can easily complete the test documentation. The variables used in the measurement process and the test results are saved on the disk, and the data is saved in text format and can be opened by Excel or text editor.

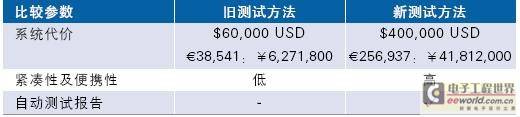

Table 1. Comparison between new and old test systems

System Performance

The VIs we developed for automated verification meet all the requirements. They exceed the old test system in terms of test speed, cost, and compactness while meeting the accuracy requirements of different functional tests . Each VI completes the data acquisition, measurement, and comparison with thresholds. The GO or NO GO flag controls the power supply shutdown in the event of a failure or completes the final test report after storing the test results . The table above compares the old test system and the new system based on Vi.

The main reason for the reduction in test time is the ability to perform the steps of control system configuration, data acquisition and display, and test report generation in succession.

in conclusion

The low-cost virtual instrument system based on user-developed VI is highly cost-effective. LabVIEW, as the key, provides DAQ hardware integrated in the test equipment and automated test plans and documents. LabVIEW's flexible and friendly graphical programming environment greatly shortens system development time.

This study serves as a foundation for implementing easily modifiable systems in further hardware and software platform development, and can even integrate other types of tests or complete similar system tests .

Previous article:How to Create and Tune a LabVIEW x86 Client DLL with Multicore Support

Next article:LabVIEW and SCXI provide a configurable measurement system for helicopters in flight

Recommended ReadingLatest update time:2024-11-16 14:31

- Popular Resources

- Popular amplifiers

-

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang)

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang) -

Arduino Nano collects temperature and humidity data through LabVIEW and DHT11

Arduino Nano collects temperature and humidity data through LabVIEW and DHT11 -

Modern Testing Technology and System Integration (Liu Junhua)

Modern Testing Technology and System Integration (Liu Junhua) -

Computer Control System Analysis, Design and Implementation Technology (Edited by Li Dongsheng, Zhu Wenxing, Gao Rui)

Computer Control System Analysis, Design and Implementation Technology (Edited by Li Dongsheng, Zhu Wenxing, Gao Rui)

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- There are three questions about LC series-parallel circuit, transistor static operating point, and 4G 5G diffraction capability.

- EEWORLD University ---- Live Replay: Microchip Security Series 10 - Automotive Cybersecurity

- Appearance characteristics of chip resistors

- Has anyone used a 15v to 3.3v converter?

- When low EMI power supplies meet crowded circuit boards, what do you do?

- EEWORLD University ---- OpenCV 3 with Python 3 Tutorial

- Siemens 230RC opens for 3 seconds and closes for 3 seconds

- Stack Overflow Technology from Entry to Mastery

- Design of Automatic AC Voltage Stabilizer

- Competition control competition materials and excellent works sharing

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang)

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang) Arduino Nano collects temperature and humidity data through LabVIEW and DHT11

Arduino Nano collects temperature and humidity data through LabVIEW and DHT11

京公网安备 11010802033920号

京公网安备 11010802033920号