1. Hardware circuit

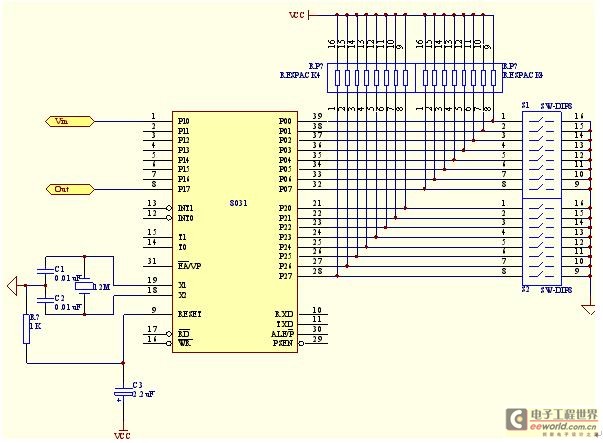

As shown in Figure 13 , the design principle diagram of the flow measurement system based on the eddy flow sensor is shown. In this experiment, we use P1.0 as the input and connect it to the output of the eddy flow sensor . In order to improve the measurement accuracy of the flow, we use P0 and P2 as the frequency multiplication input. Under different flow conditions, we choose different frequency multiplication. Obviously, when the measured flow is large, the frequency multiplication we choose will be reduced accordingly, and the accuracy will be reduced accordingly; vice versa. In this experiment, we use P1.7 only to verify whether the frequency multiplication is correct.

Figure 12 Schematic diagram of flow measurement system design based on eddy current flow sensor

2. Circuit Principle

Specific implementation process:

(1) Use the level change of the P1.0 signal and timer T0 to measure the period of the input signal: Set timer T0 to mode 0 timing. Before the rising edge of P1.0 arrives, start timer T0 to start counting the internal clock. After the next rising edge of P1.0 arrives, turn off timer T0 and read the count value M to start the next timing process. The input signal period is:

(4) The output signal should not only be frequency-multiplied, but also be in phase with the input signal, that is, the rising edge of the frequency-multiplied output signal should appear at the same time as the rising edge of the input signal. In analog circuits, automatic phase synchronization is achieved by a phase-locked loop circuit, which gradually achieves the synchronization purpose by phase detection and closed-loop adjustment of the input and output signals. In digital circuits, synchronous phase locking can be achieved by controlling the starting point of the output signal relative to the input signal. To this end, synchronization takes one input signal cycle as a period. At each rising edge of the input signal, timer T1 is started and P1.7 outputs a high level. After timer T1 generates (2N-1) timing interrupts, timer T1 is turned off and P1.7 outputs a low level, waiting for the synchronization moment of the next period.

3. Experimental Procedure

Figure 13 Phase-locked frequency multiplication Program flow chart

To summarize, the flow rate Q measured by the eddy current flow sensor is the pulse frequency f0 output by P1.7 divided by the product of the frequency division number and 48.67, that is, Q=f0/(48.67*N).

Previous article:Design of omnidirectional solar irradiance measurement system

Next article:Remote Data Acquisition and Measurement Based on INTERNET

Recommended ReadingLatest update time:2024-11-17 01:29

- Popular Resources

- Popular amplifiers

-

Analysis and Implementation of MAC Protocol for Wireless Sensor Networks (by Yang Zhijun, Xie Xianjie, and Ding Hongwei)

Analysis and Implementation of MAC Protocol for Wireless Sensor Networks (by Yang Zhijun, Xie Xianjie, and Ding Hongwei) -

Introduction to Internet of Things Engineering 2nd Edition (Gongyi Wu)

Introduction to Internet of Things Engineering 2nd Edition (Gongyi Wu) -

西门子S7-12001500 PLC SCL语言编程从入门到精通 (北岛李工)

西门子S7-12001500 PLC SCL语言编程从入门到精通 (北岛李工) -

Modern Motor Control Technology (Wang Chengyuan, Xia Jiakuan, Sun Yibiao)

Modern Motor Control Technology (Wang Chengyuan, Xia Jiakuan, Sun Yibiao)

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- Rambus Launches Industry's First HBM 4 Controller IP: What Are the Technical Details Behind It?

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- Have you ever used a domestic DAC chip?

- Raspberry Pi 2 Model B Review - by freebsder

- Are there any experienced teachers in the motor control field?

- [RVB2601 Creative Application Development] RVB2601 Get Weather Widget

- Make a shy mask by yourself, shut up when you see people, and drink milk tea while wearing it

- Today at 10:30, Microchip's live broadcast with prizes is in progress...

- Relay contact material selection question, please answer

- Current Sensing Using Nanopower Op Amps

- Smart Micro MM32SPIN25PF is compatible with MM32F031CBT6

- TMS320F28335 GPIO pin general input/output port

Analysis and Implementation of MAC Protocol for Wireless Sensor Networks (by Yang Zhijun, Xie Xianjie, and Ding Hongwei)

Analysis and Implementation of MAC Protocol for Wireless Sensor Networks (by Yang Zhijun, Xie Xianjie, and Ding Hongwei)

京公网安备 11010802033920号

京公网安备 11010802033920号