O Introduction

Electronic instruments and test laboratories are essential teaching experimental conditions for higher engineering colleges. In order to provide a certain experimental scale and ensure that each student can get practical hands-on training, traditional teaching laboratories generally need to purchase a large number of basic measuring instruments, such as oscilloscopes, voltmeters, signal sources, etc., which require large investments, fast technology updates, and difficult maintenance. Voltmeters are one of the indispensable measuring instruments.

Traditional digital voltmeters are designed using A/D converters and general integrated logic devices. Such designs are not convenient for system function modification and upgrading, lack flexibility, have complex wiring, and have a high failure rate. The digital voltmeter design with a single-chip microcomputer as the core is currently the most widely used design method, but its working speed is low, and function modification and debugging require the support of hardware circuits.

In the design of this article, the new technology of virtual instrument is combined to complete the design of digital voltmeter, which is not only more conducive to system integration, improves the test accuracy of the system, is suitable for laboratory measurement, and solves investment, maintenance and other problems, but also takes into account that the instrument is mainly used for teaching and experiments. When using it, students can define the function of the instrument according to their needs through operation and setting parameters; at the same time, modern measuring instrument systems are developing towards intelligence, automation, miniaturization, modularization and open systems, and electronic measuring instruments based on virtual instruments can meet this requirement.

1 System design and principle

1.1 System hardware design

Virtual instrument (VI) is a new concept proposed by

National Instruments

Corporation (NI)

in the late 1980s

. It is based on general-purpose computers and has specific hardware interfaces. Users can write applications through software development platforms to complete the functions of traditional instruments. Virtual instrument technology has been widely accepted and used in the industry and has become the mainstream of instrument technology.

According to the overall structural analysis of the virtual instrument, its structure diagram is shown in Figure 1. The internal functions of the virtual instrument can be divided into three functional modules: data acquisition and control, data analysis, and data expression. According to the different measurement and control function hardware, VI can be divided into four standard architectures: GPIB, VXI, PXI and DAQ. This design adopts the PC-DAQ architecture.

[page]

[page]

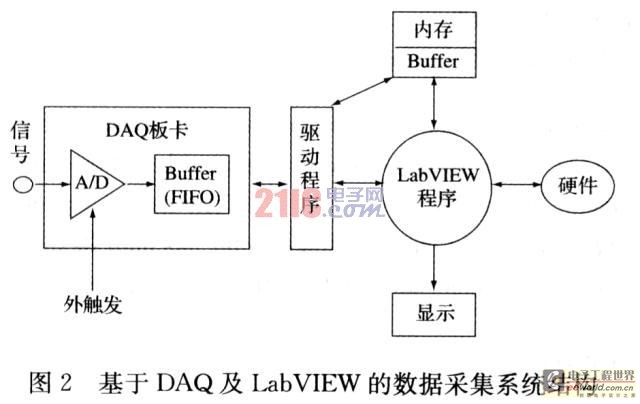

Data acquisition is one of the core technologies of LabVIEW. It is also the advantage of LabVIEW compared with other programming languages. In the design, PC-DAQ (Data AcQuisition) architecture is adopted according to the characteristics of the test system. The data acquisition part adopts NI USB-6009 DAQ, 8-channel single-ended input of analog signal, and the maximum sampling rate is 42kSa/s (multi-channel total). The data processing and data display part is implemented in the PC with LabVIEW 8.2. The PC configuration is: Pentium 4 CPU 2.00GHz, memory 256MB, hard disk 60GB. The acquisition system structure diagram is shown in Figure 2.

1.2 Voltmeter Design Principle

The digital voltmeter based on DAQ and LabVIEW includes the functions of DC voltmeter and AC voltmeter. The design principle of the DC voltmeter is shown in Figure 3, which adopts the voltage-time conversion principle. The

voltage-time conversion principle means that the measured voltage value is converted into the time interval △t during measurement. The larger the voltage, the larger the △t. Then the timing pulse is controlled according to the size of △t to count, and the count value is the voltage value. The voltage-time conversion type is also called VT type or ramp voltage type.

Traditional AC voltmeters are divided into peak voltmeters, mean voltmeters and effective value voltmeters according to the output response to the waveform. Their working principles are similar, but the parameters of the detection circuit are different: the peak voltmeter uses a diode peak detector, and the deflection of the meter head is proportional to the peak value of the measured voltage (arbitrary waveform); the average voltmeter generally uses a diode full-wave or bridge rectifier circuit as a detector, and the meter head deflection is proportional to the average value of the measured voltage; the effective value is often measured by thermoelectric conversion and analog calculation circuit. Therefore, different measuring instruments must be selected for different measurement objects.

2 Software Programming Based on LabVIEW

2.1 Software System of Virtual Instruments

In system design, the key to traditional instruments is hardware, while the key to virtual instruments is software. The core idea is to use the hardware/software resources of computers to softwareize (virtualize) the technology that originally requires hardware implementation, so as to minimize system costs and enhance the system's functions and flexibility. Therefore, to complete the test function of virtual instruments, software design is the key.

LabVIEW is a graphical programming language that is mainly used to develop software such as data acquisition, instrument control, and data processing and analysis. It is currently popular in the international testing and measurement and control industries, and is also widely used in the domestic measurement and control field. It greatly reduces the difficulty of program design, allowing test engineers to focus on realizing instrument functions rather than struggling with program text codes. The design of virtual instrument test software based on LabVIEW includes the design of the front panel and the design of the background graphical control program.

2.2 Software implementation of voltmeter based on virtual instrument technology

According to the principle and test method of digital voltmeter analyzed above, the system can complete the test function of DC and AC voltage. The voltmeter designed in this paper is mainly used as laboratory teaching equipment, mainly to let students master the circuit structure of voltmeter, the working principle of voltmeter, the test method of voltmeter and the different responses of AC voltmeter to sine waveform and non-sinusoidal waveform. Then the virtual voltmeter should have the functions of power switch control, input parameter control, waveform display, peak value, effective value and average value, and adjustable sampling of input signal. [page]

Based on the analysis of the principle of digital voltmeter and the general method of program design, the software flow chart of the virtual DC voltmeter is shown in Figure 4.

The front panel is shown in Figure 5.

The front panel consists of two parts: input control and output display. It is easy to operate and has a friendly interface. Input control is used to control the operation mode of the system. The system can perform two functions: simulation and testing. The range selection is used to set the voltage range. For different DC inputs, the detection range is set; the output display is used to display the measurement results. Two display controls are used to display the voltage waveform to be measured and the standard voltage waveform. At the same time, the panel simulates the pointer of the pointer instrument to indicate the size of the measurement. The two Boolean array indicator controls respectively display the results of each comparison and whether the range is exceeded. Due to the randomness of the test, the program also designs an automatic alarm function.

2.2.2 Implementation of AC voltmeter

Based on the analysis of the principle of AC voltmeter, in the design process, the tool module provided by LabVEW is used to analyze the collected voltage signal through different forms of detection, calculation, etc. to obtain the effective value, peak value and average value of the AC voltage signal. For a pure AC voltage, the positive half-cycle signal and the negative half-cycle signal are symmetrical, and the average value is equal to zero, so we generally do not directly measure the average value. When designing, press Functions>>Nu-meric>>Absolute value to get the absolute value of the AC voltage, and then find the average value, that is, the full-wave average value; the maximum value of the AC voltage is the peak value. The data can be compared to find the maximum value, which can be processed through Waveform MinMax; DC value is used to measure the DC component and RMS value is used to measure the effective value. In this way, all the tests that rely on hardware circuits are implemented by software, improving the performance and integration of the system. The design flowchart is shown in Figure 6.

In the test, the voltmeter designed based on USB6009DAQ can sample the highest frequency of the sine signal to be 65000Hz, and the highest amplitude of the displayed waveform is 11.35V. [page]

3 System Analysis

The range of the virtual DC voltmeter affects the accuracy of the test for different DC inputs. When measuring voltage, the measured voltage should be above 2/3 of the range. The general range should be selected to be more than 3 times the measured voltage. When the input DC test signal is between 0 and 3V, the test range should be selected at 10V, and the test error is basically 0.0012V. During AC testing, the signal generator is used to send out the test signal, and the test values of the virtual voltmeter and multimeter are compared with the oscilloscope. The test values of the virtual voltmeter are shown in Table 1. During the test, attention should be paid to setting the sampling rate reasonably, which is an important way to reduce the measurement error.

The measured values of the oscilloscope and the digital multimeter (three and a half digits) are shown in Table 2.

The average value of the sine wave peak value measured by the virtual instrument is: 11.49801V.

The average value of the sine wave peak-to-peak value measured by the multimeter is: (23+23+23+23+23+23+23+23+23+23)/10=23 V, and the peak value is: 11.5V. The measurement error of the two instruments is 0.00199V. It can be seen that the designed virtual voltmeter can meet the measurement needs of the laboratory.

4 Conclusion

The digital voltmeter based on DAQ and LabVIEW can realize the functions of the digital voltmeter. The visual front panel controls construct the user interface of the instrument, which has strong human-computer interaction and a friendly interface. After debugging and running, the design can meet the design requirements of the digital voltmeter for laboratory use; and the system function expansion is convenient. By adding some software, the functions of filters and signal sources can be realized, which can solve the problems of technical update and maintenance difficulties of existing experimental equipment.

Previous article:Dynamic Test System of Radio Altimeter Based on Virtual Instrument Technology

Next article:LabVIEW Robotics Module - Special Algorithms and APIs in the Robotics Palette

Recommended ReadingLatest update time:2024-11-16 21:55

- Popular Resources

- Popular amplifiers

-

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang)

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang) -

Arduino Nano collects temperature and humidity data through LabVIEW and DHT11

Arduino Nano collects temperature and humidity data through LabVIEW and DHT11 -

Modern Testing Technology and System Integration (Liu Junhua)

Modern Testing Technology and System Integration (Liu Junhua) -

Computer Control System Analysis, Design and Implementation Technology (Edited by Li Dongsheng, Zhu Wenxing, Gao Rui)

Computer Control System Analysis, Design and Implementation Technology (Edited by Li Dongsheng, Zhu Wenxing, Gao Rui)

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- LSM6DSR iNEMO inertial module related information

- Qorvo Receives Samsung Mobile Quality Award

- PCI Bus

- Meditations on MCU——static

- A Field Guide to the Internet of Things

- Comparison of these two circuit structures

- Can the op amp inputs exceed the power supply range?

- The fight against the epidemic has made the improvement of medical electronic technology a focus of attention. Let’s take a look at this article. What do you think?

- SDRAM controller.rar

- Sharing--Wireless Charging Bluetooth Speaker Manufacturing Process and PCB Design Appreciation

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang)

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang) Arduino Nano collects temperature and humidity data through LabVIEW and DHT11

Arduino Nano collects temperature and humidity data through LabVIEW and DHT11

京公网安备 11010802033920号

京公网安备 11010802033920号