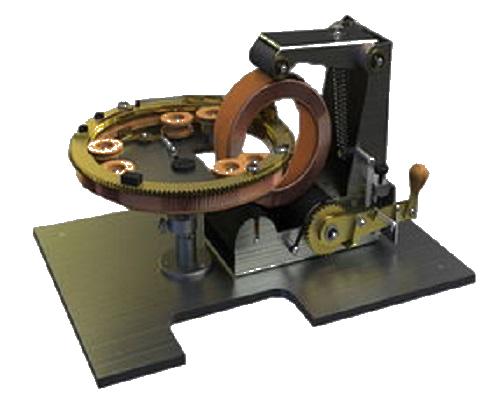

Winding machine used to produce toroidal transformers and toroidal coils - toroidal winding machine

Source: InternetPublisher:司马缸砸光 Keywords: Magnetic ring ring winding machine flat winding machine Updated: 2020/10/25

What is a toroidal winding machine? What is its function? Simply put, a toroidal winding machine is a winding machine used to produce toroidal transformers and toroidal coils.

composition:

The ring winding machine consists of three parts: the machine head, the clamp, and the machine base. Unlike the flat winding machine, the same machine head can only be used for different wire diameters after replacing wire storage rings of different specifications. Products with different inner diameters are wound, and the clamps also have corresponding clamping ranges.

Generally, there are the following consumable parts on the ring winding machine that need to be replaced frequently:

(1) The wire storage ring, also called the steel ring (Shuttle), is one of the most important parts of the machine head. It is used to complete wire storage and winding work; its quality directly affects the service life and indirect costs. and the quality of the wound products.

(2) Support wheels, also called guide wheels. Different machine heads have different numbers of support wheels, and their materials are directly related to their service life.

(3) Clamp roller, the life of this component is related to the wire diameter, size and material of the wound product.

(4) Belts, side sliders and other consumable parts.

working principle:

Fix the magnetic ring, pass the wire through the magnetic ring and hand it to the robotic arm. The robotic arm will pull out the required length of winding in one go. Then it comes to the beginning of the magnetic ring. The wire passes through the magnetic ring for the second time and is handed to another clip. Temporarily fixed, the robotic arm returns to the end to clamp the wire, and then performs a second cycle. The wire passes through the magnetic ring for the third time, and the loop is completed in a reciprocating cycle.

The ring winding machine consists of three parts: the machine head, the clamp, and the machine base. Unlike the flat winding machine, the same machine head can only be used for different wire diameters after replacing wire storage rings of different specifications. Products with different inner diameters are wound, and the clamps also have corresponding clamping ranges.

In general, not only the products produced by the ring winding machine are completely different from those of the flat winding machine, but the consumption cost of the entire life cycle is also greatly increased. Once a flat winding machine is purchased, it generally only incurs the cost of making different tools. However, after a ring winding machine is purchased, different wire storage rings and support wheels need to be replaced according to the wire diameter and size of the products produced. Since the copper wire is always stored from the storage One side of the wire loop slides out (belt type and side sliding type), and the wire storage ring is unevenly stressed. After a certain period of time, the wire storage ring and the support wheel need to be replaced before production can continue! Of course, the added value of the toroidal coil is higher than the average The winding is much higher and can completely bear the cost.

Precautions:

In general, not only the products produced by the ring winding machine are completely different from those of the flat winding machine, but the consumption cost of the entire life cycle is also greatly increased. Once a flat winding machine is purchased, it generally only incurs the cost of making different tools. However, after a ring winding machine is purchased, different wire storage rings and support wheels need to be replaced according to the wire diameter and size of the products produced. Since the copper wire is always stored from the storage One side of the wire loop slides out (belt type and side sliding type), and the wire storage ring is unevenly stressed. After a certain period of time, the wire storage ring and the support wheel need to be replaced before production can continue! Of course, the added value of the toroidal coil is higher than the average The winding is much higher and can completely bear the cost. The above is the analysis of the ring winding machine, I hope it can help you.

- 5 Converter Topologies for Integrated Solar and Storage Systems

- Single-power supply circuit for ISO122P/ISO124

- BA6104 five-digit LED level meter driver integrated circuit basic application circuit

- Isolated two-wire current loop circuit (XTR101, ISO100)

- Driving circuit that controls LED brightness using PWM signal

- LED Driver ZD1680

- Dynamic power supply for power amplifier controlled by thyristor

- Adjustable regulated power supply with current limiting protection

- MAX1811 Lithium Battery Charger Production

- Automatic charger made with LM3914

- Winding machine used to produce toroidal transformers and toroidal coils - toroidal winding machine

- Power circuit of STR5412

- Power circuit b composed of intelligent thyristor modules

- Output 12V-10A power supply circuit

- Three-way DC-DC converter circuit

- 300A-18V three-phase thyristor voltage regulating electrolytic power supply circuit

- Diamond differential input power amplifier power circuit

- Karaoke light controller circuit (1)

- Common power circuits and applications 05

- Always ready power circuit

京公网安备 11010802033920号

京公网安备 11010802033920号