Creating detailed, simulation-friendly CFD models for automotive applications is not an easy task and requires a lot of manual work. This is a challenge faced by every OEM, and Toyota Motor Europe wanted to find a solution to this problem and significantly shorten the overall design cycle. In the end, they completely eliminated the previous manual process through an innovative CFD pre-processing workflow.

Toyota's watertight geometric surface can automatically create sealing patches

Accurately predicting the vehicle's exterior aerodynamics, heating, ventilation, and air conditioning effects requires setting up a simulation domain that includes a large number of components in CAD format. The main difficulty in dealing with so many components is creating the "watertight surfaces" that are required for proper CFD analysis with a finite volume solver. To do this, gaps need to be filled, surfaces that are not in contact with the fluid need to be eliminated, and interference issues need to be resolved before generating the surface and volume meshes. These tasks are usually done manually before using pre-processing software with CAD processing and meshing capabilities, which is labor-intensive and extremely time-consuming.

“

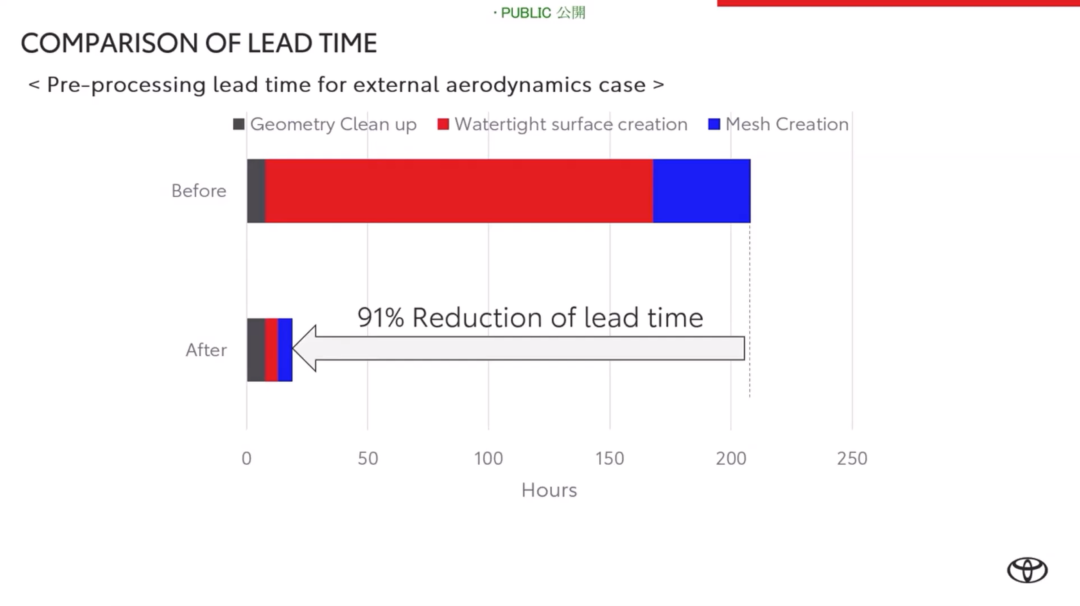

Automated CFD pre-processing workflow reduces our total lead time by 91% and man-hours by 97%

At Toyota Motor Europe, we have chosen Cadence Omnis Autoseal and Omnis Hexpress as our standard workflow for CFD pre-processing. This has reduced our total lead time and man-hours by 91% and 97% respectively, while providing high-quality meshes and excellent layer coverage. Thanks to the high degree of automation and standardization, we can easily generate meshes from CAD models without long learning curves.

——Antoine Delacroix

Vehicle Performance Engineering R&D Manager, Toyota Motor Europe NV/SA

In a webinar hosted by Cadence, Antoine Delacroix, R&D manager of Toyota Vehicle Performance Engineering, explained in detail how they established an automated pre-processing workflow that combines the powerful gap-filling capabilities of Cadence Omnis AutoSeal with the Omnis Hexpress “body-to-mesh” approach to completely eliminate manual work in the process. This process enables them to generate runnable models in a split second with little to no manual intervention, greatly reducing simulation cycle times.

It is recommended to watch in a WIFI environment and pay attention to adjusting the volume

Omnis software technology and workflow are now integrated into the Cadence Fidelity CFD software platform, a comprehensive computational fluid dynamics (CFD) solution for a variety of industries, including automotive, turbomachinery, marine, aerospace, etc.

Fidelity CFD introduces a new generation of fluid solvers that provide high-order numerical formats, scale-resolved simulations, and massive hardware acceleration capabilities to help improve simulation performance and reduce development cycles while ensuring accuracy.

Previous article:CANape High-Performance Data Logging and DDS

Next article:Corelit's ultra-low power domestic SIT1043 CAN transceiver is used in automotive ECUs

Recommended ReadingLatest update time:2024-11-16 09:40

- Popular Resources

- Popular amplifiers

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- What are the functions of the Internet of Vehicles? What are the uses and benefits of the Internet of Vehicles?

- Power Inverter - A critical safety system for electric vehicles

- Analysis of the information security mechanism of AUTOSAR, the automotive embedded software framework

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Are there any recommended books for beginners in circuit development?

- MSP430 G2553 Launchpad implements capacitance measurement

- [GD32L233C-START Review] 12. Button - External Interrupt

- [Qinheng RISC-V core CH582] Environment configuration and lighting test

- Design and implementation of image cropping circuit based on FPGA

- MSP430 Launchpad MSP430g2452 SHT10 Temperature and Humidity Sensor

- Establishment of RF chip/modem chip design team

- F28335 uses external SRAM for program simulation

- Looking for experts in Helmholtz coil magnetic field

- How to use the VGA_SYNC_N signal in the VGA of DE1-SOC?

More Hot Air (Tony Kordyban)

More Hot Air (Tony Kordyban)

京公网安备 11010802033920号

京公网安备 11010802033920号