The electric drive system mainly consists of three parts: motor, motor control unit and reducer:

Most of the time, user needs determine the direction of product technology evolution.

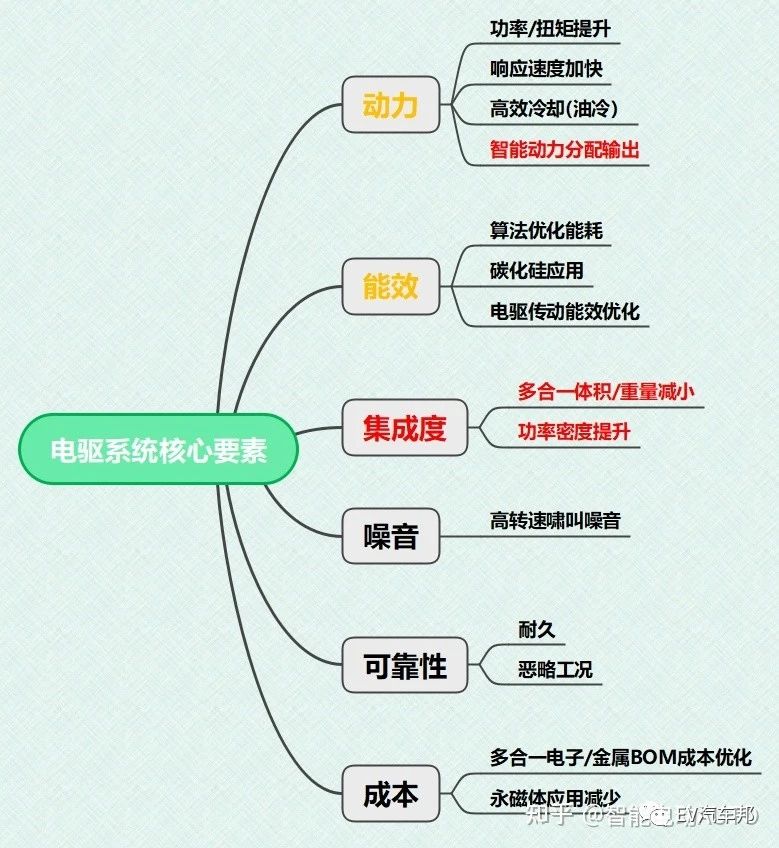

The core requirements of power units are: ① fast response and strong power; ② high efficiency and low energy consumption; ③ low failure rate, durable, stable and reliable. More potential requirements are: ① high integration to make more space in the car and front and rear trunks; ② reasonable cost (which will eventually be reflected in the price of the car); ③ no whistling and annoying at high speeds. The figure below summarizes the core elements of electric vehicle power units. In fact, the technology and evolution of electric drive systems are all centered around these aspects.

1. The power of the motor is currently sufficient, and there is little potential and necessity to squeeze it. In terms of the most important attribute of electric drive, "power", most electric vehicles currently have excess power. Take the 36w+ Tesla Model 3P as an example. Its acceleration can beat a performance gasoline car of around 200w in seconds. The 3w Hongguang MiniEV's starting acceleration is even more direct than many gasoline cars.

△ Some high-performance motor power parameters That is to say, the motor power is sufficient for most electric vehicles at present, and the high horsepower premium of traditional gasoline vehicles has become worthless on electric vehicles. The high power density motors listed in the above figure give people the feeling that the horsepower of electric vehicles is given for free. Instead of spending a lot of money on developing new power products and improving power parameters based on the existing more than enough motor power, car companies should spread the cost to other places that users can feel more.

Of course, for a few performance electric vehicles that pursue absolute power acceleration, such as Tesla Model S Plaid, Lucid Air sapphire, Hummer EV, Porsche Taycan Turbo S and other models. There are some new key technologies to improve power: such as flat winding coils, end transposition to increase slot fill rate, and optimize rotor structure to increase magnetic full rate, further improve motor power and power density. In recent years, more and more models have been equipped with direct waterfall oil-cooled motors to make motor cooling more efficient and help power output to continue without attenuation. There are also intelligent algorithms to optimize motor power output to achieve better power, energy consumption, and stable control. Personally, I think the above technologies are all considered core electric drive technologies!

2. The energy efficiency of motors has reached a bottleneck, and improving energy efficiency requires the application of silicon carbide

Based on the premise in Part 1 that motor power is sufficient or even excessive for most users, the following figure is a motor energy efficiency map. It can be clearly seen that in most daily speed ranges, the motor's energy efficiency is above 90%.

Moreover, the best energy efficiency of motors installed in most new energy vehicle models is currently between 90% and 95%, and some high-efficiency motors have even reached 96%. At this time, if you want to continue to improve the motor efficiency on the existing basis, the cost will increase exponentially, which is not so cost-effective for both car companies and users.

△ Energy efficiency MAP diagram of a motor

Therefore, improving the energy efficiency of the main inverter in the motor control unit has become a new direction for improving the energy efficiency of the entire electric drive system.

That is to replace the current mainstream IGBT modules with SiC silicon carbide modules!

△ Advantages of Silicon Carbide Materials

Silicon carbide SiC MOSFET has many advantages, including small size for packaging and integration, fast switching/conduction response and lower loss, high voltage resistance (10 times that of silicon-based), high thermal conductivity for heat dissipation, and higher power density.

△ Analysis of the advantages of silicon carbide

The most important thing is the motor control unit using SiC silicon carbide modules. Compared with the IGBT module solution, it can achieve an efficiency improvement of about 5% from the battery to the motor path, which means that it can save about 5% of the energy consumption of the entire vehicle.

Compared with the battery cost corresponding to the 5% increase in battery life used by car companies, and the negative impact of increasing the weight of the vehicle, even the silicon carbide module, which currently has a higher cost than IGBT, is the best choice!

In addition, compared with IGBT, silicon carbide has the advantage of being more resistant to high voltage (above 1,000 volts), and is more suitable for the 800V electrical architecture that more new energy vehicle models will be equipped with in the future. It is not only used in the main inverter, but can also be applied to high-voltage charging piles, high-voltage battery packs, OBC chargers, and DC-DC converters. It will have a greater place to be used and can further improve the energy efficiency and charging experience of the entire vehicle!

△ Application of silicon carbide devices in new energy vehicles

Here I would like to give special praise to the domestic brand BYD. BYD is the only car company in the world that has achieved self-developed and self-produced silicon carbide devices!

3. Integration has great potential and is the general trend. Cross-system integration capabilities will be the core technical competitiveness and provide higher user value!

The above mainly discusses the upgrade and optimization of individual components of the electric drive system. The all-in-one integration of electric drive system components is currently the general trend in the industry!

The highly integrated electric drive system has many advantages:

Greatly save volume and weight, reduce overall BOM cost, improve integrated assembly efficiency, and increase the overall power density of the electric drive system...

The value to users lies in that the small size saves more layout space, resulting in larger interior space and front and rear trunk volumes; reduced weight means longer mileage with the same amount of power; at the same time, BOM cost reduction also indirectly reduces users' purchase costs.

The evolution history of electric drive systems can be roughly divided into three stages:

From 2015 to 2017, there were three separate components. From 2018 to 2020, three-in-one became the mainstream. From 2021 to now, there is an integrated stage of all-in-one.

Although all-in-one is just a combination of components from multiple systems, system integration across components and fields is a test of technical and engineering capabilities. Currently, only a few large companies with accumulated experience can do it.

Compared with motor power improvement and energy efficiency optimization, the comprehensive benefits brought by all-in-one integration will be more obvious, and it is undoubtedly one of the most important core technologies of new energy vehicle electric drive systems!

Previous article:In-depth discussion of the principles and applications of core technologies for new energy vehicles

Next article:What are the semiconductor devices in automotive electronics?

- Popular Resources

- Popular amplifiers

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- What are the functions of the Internet of Vehicles? What are the uses and benefits of the Internet of Vehicles?

- Power Inverter - A critical safety system for electric vehicles

- Analysis of the information security mechanism of AUTOSAR, the automotive embedded software framework

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- I would like some advice on troubleshooting the mnemonic reading device in the analog circuits book?

- Summary of STM32 serial port sending and receiving data

- A brief explanation of FPGA static timing analysis

- [TI star products limited time sale] + Buy, buy, buy!

- [Xianji HPM6750 Review] CoreMark running test

- [Runhe Neptune Review] Six-tone LED light

- Huawei Electromagnetic Compatibility Structural Design Specification V2.0

- TMS320F28035 timer interrupt routine

- [TI mmWave Radar Evaluation] 5+AWR1443 EVM Board Sensitivity (Minimum Distance) Test and Summary

- 【ESP32-S2-Kaluga-1 Review】Getting weather information via https

Multi-port and shared memory architecture for high-performance ADAS SoCs

Multi-port and shared memory architecture for high-performance ADAS SoCs

京公网安备 11010802033920号

京公网安备 11010802033920号